I will start off by saying DO NOT try and short cut this job. As you’ll see I went all around the houses just to end up doing what I wanted to avoid.

I sourced a solid small bore manifold and think it’ll be a much better fit for my engine set up than the large bore Janspeed flexi I have currently. I believe it is an EBD manifold going by the fixing bracket by the cat end, which Dave Andrews highly recommends on his website. Although my head is a Vulcan head (near identical to a VHPD) as far as I’m aware it hasn’t had any additional porting, so the large bore is probably not the best option. The small bore should match the port size much better and the longer pipe sections replacing the flexi section should improve torque a little bit.

First step was to remove the sports cat. Pretty much a decat pipe with a bit of baffling in the middle.

Next step was to remove the flexi section. Nice and easy with just 2 nuts to undo and it slide through the hole and away.

Although it fit through the gap between the heat shield and brace bar, I would have to remove one of the fixings on the brace bar to allow the solid one to fit before bolting it back.

To save the fuse blowing in the alternator I found the fuse and removed it. As a bit of extra protection I also disconnected the battery.

Before I went too far I tested to see if any of the manifold nuts would be a pain. Thankfully as they were recently put on when the Janspeed went on they all came loose fine and left the bolts in the head.

Next up was to remove the nimbus heat shield. His was new on when the Janspeed went on and fixed up 4 bolts, 2 at the top and two at the bottom, which were only accessable from under the car.

With the heat shield out the way I took the 5 manifold bolts off and put them somewhere safe.

I then unplugged the lambda sensor. The new manifold had a sensor with it that was pretty new so not going to bother swapping them over.

I removed a couple of bolts for the throttle cable and moved it to the side to get a bit more clearance.

I was hoping to avoid taking the engine mounts off, but I just couldn’t get the clearance. I started with the lower engine stay bolt which let me rock the engine back and forth a bit, but it wasn’t enough.

I supported the engine underneath while I undone the RH side engine mount. This allowed me to pull the engine back a bit, but still not enough to give me clearance. I also removed the alternator in a failed attempt to get the required clearance.

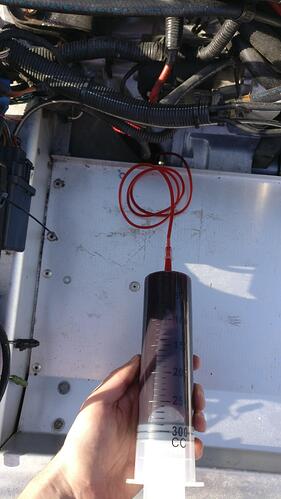

In the end I decided the only way I was getting the manifold out was to remove the oil filter. I don’t have any oil here at the moment so wanted to avoid this, especially as the oil in there is less than 300 miles old. I placed a bucket underneath and removed the bleed bolt on the sump. Once that was drained I removed the oil filter and let the remaining oil in the drain out.

All this fuss could have been avoided if I’d just made the decision to remove the oil filter. I honestly don’t know how you’d get the manifold out without removing it. Don’t do what I do and try to take short cuts because it won’t work here, or certainly I couldn’t make it work.

With the manifold off I was able to measure the size of the exhaust ports. Being a metric person I don’t really know inches, but I believe that’s how exhausts are measured.

What I was happy to learn was that the new manifold would match the exhaust port so there would be no nasty step either too small or large.

The Janspeed manifold may have been better if the exhaust was ported more, but I’m confident that I’ve made the right choice for this engine and head.

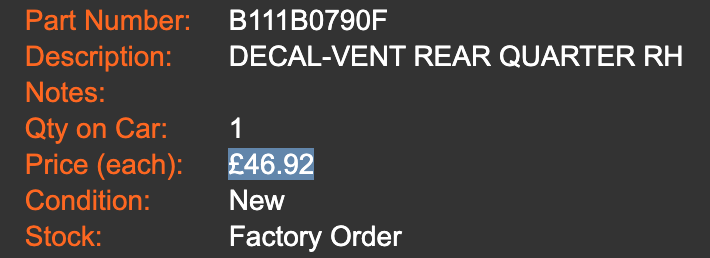

Here’s the hole I would have to fill with the new manifold.

I got all new gaskets ready to put everything back together.

I got the new manifold most the way, but had to drop one side of the brace bar down to allow the manifold up into the gap.

I got the manifold onto the studs but couldn’t get it sitting flush on its own, so I had to use the nuts to pull it against the gasket.

I torqued them down to 45nm in the order shown.

I popped the heat shield back on along with all the other bits and bobs I removed to get the proper position on the manifold for the next step.

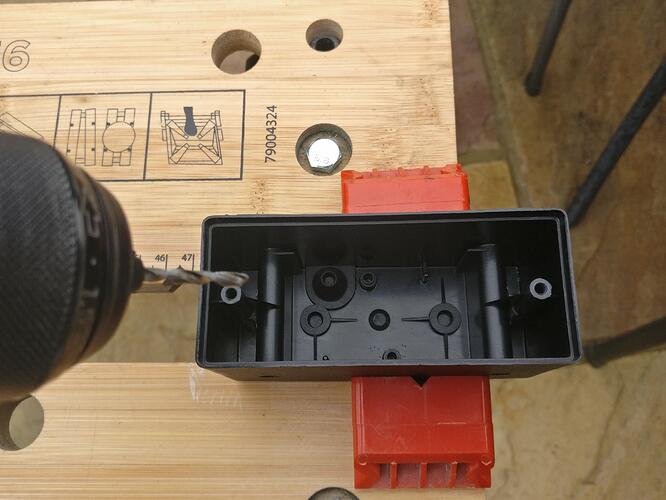

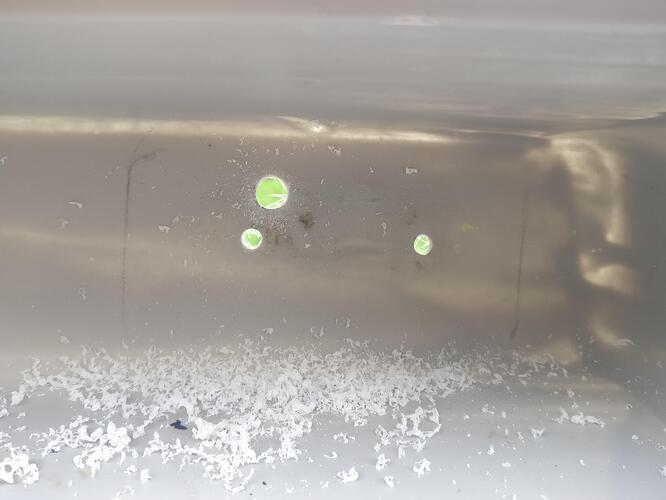

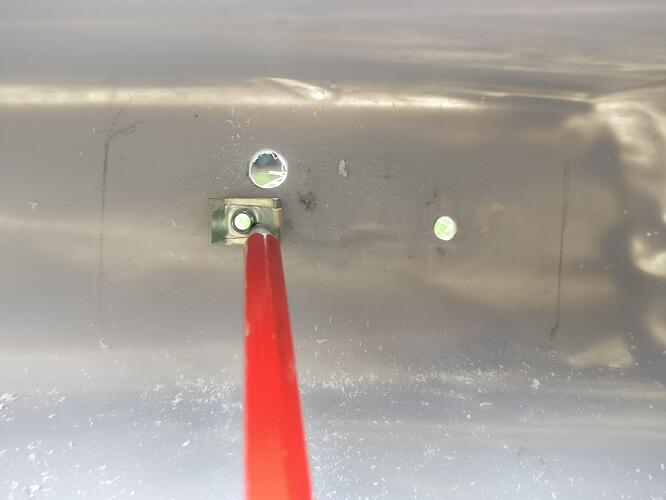

The manifold didn’t come with a fixing for the back section, so I had to make one. It is very DIY and bodge but I am hoping it will do the job. It would give me some adjustment room if needed. I had to drill the rubber mount lower because of the length and the gauge of the L piece.

I mounted the rubber to establish where to drill the mounting holes on the exhaust. I finished it with loctite on the threads to help secure everything. I’ll have to see if it actually works and is strong enough, but it was a very cheap way of sorting a bracket.

To finish everything I had to put the cat back on. To seal the gap I bought some exhaust paste to go with the new gaskets.

With not having any oil to fill the engine back up with I couldn’t start it to hear what it sounds like or to cure the exhaust paste, but I’m happy I don’t have to do that job again for a long time!