Not much left to get ready before the body shop now, but I tackled the sills.

First step was to get the sill protector vinyls off. These were a little bit stubborn but a bit of heat (not too much otherwise the vinyl just stretched and tore) and they came away slowly and gently.

As gentle as I could be the vinyl still took some paint off the sill. Not a real issue as I was going to sand the sill anyway and it would be covered by the Exige clam, but still a bit of a pain leaving a step in the paint I had to sand flush.

A bit of 120, then 240 before finally 320 saw the surface flush. Bit overkill for an areas that ultimately won’t be seen.

The driver sill had a sticker talking about the fuel filler cap. I tried to peel it of but it was so brittle it just broke away in tiny pieces. In the end I decided the best method would be to sand it off.

I took some 120 grit and over a little while it eventually sanded off and I blended the surrounding surfaces.

I took the front clam and doors off to allow for the masking to begin. The doors would stay off as they can be easily transported off the car and need sanding as well which will be much easier loose.

I took some frogtape and began to tape up the surrounding pieces. The interior sill but was quite easy as the tape slid underneath most bits of the aluminium and wrapped over well. I’ll let the body shop do the rest/main taping.

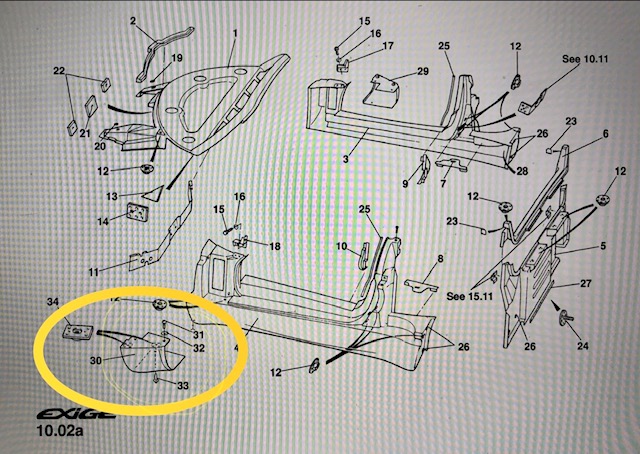

I noticed the front clam fixing needed to come off to sand behind them. I would have to put them back on afterwards to fix the front clam for transportation. Removing them also let me tape up around the windscreen. Also since these photos I have removed the extra door shim that I missed and taped over first time round.

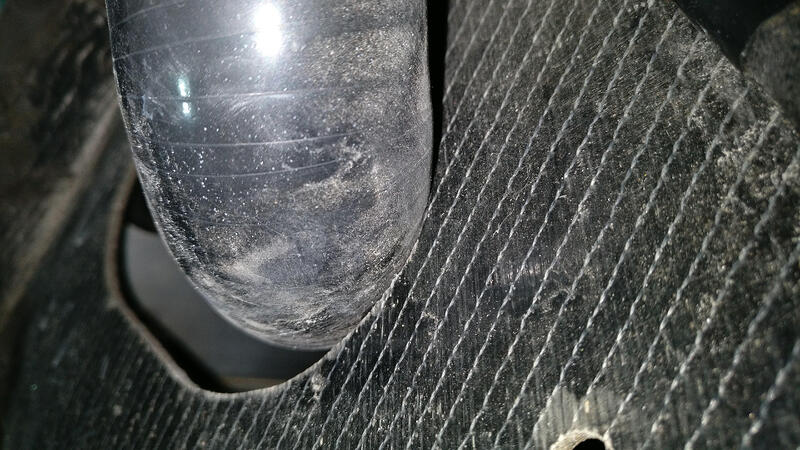

I was a little surprised to find the underside had gone rusty and had rotted the fibreglass a bit. I scraped out a bit of the loose bits but wanted to leave most the material still there as it isn’t doing any harm and gives the plate material to fix against.

I taped up around the windscreen and the front of the sill down the aluminium, plus all underneath too.

I then took the roof off to get better access to the top of the B pillar and tape up around the roll bar.

I was pretty anal with the taping, where every little jot out and kink in the tape was were the rubber adhesive was, so the respray should miss all the black adhesive and hopefully should be very hard to tell that the paint has been changed, rather than having overspray. Again probably overkill as this won’t be seen really. I did the same on the back as I did at the front and taped all down the chassis and underneath the car.

When taking the 320 grit to the sills I noticed that they were quite badly stone chipped, probably from the amount of trackdays the car does, not being a garage queen and also being nearly 23 years old. I started taking some 120 grit to it, but it was taking ages and thought it would be better to leave these areas to the body shop to quickly blitz over them with their machines.

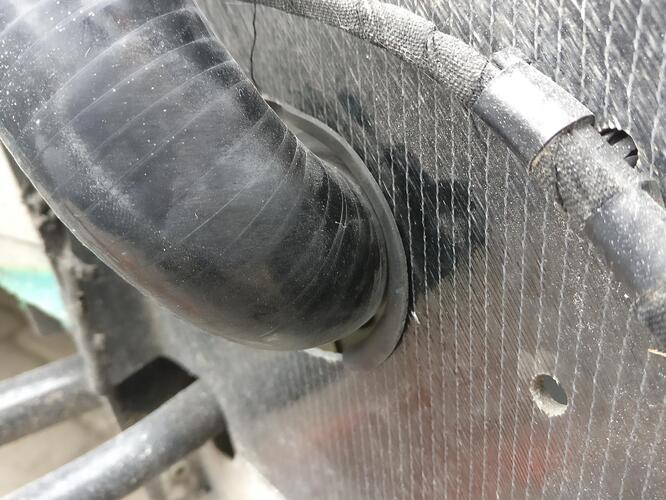

Something different on the driver’s sill is the hole in the back of the sill by the engine mount.

I was able to get my hand up into the inside of the sill and place 2 strips of tape on the underside. I could have left this open but didn’t really want paint sprayed up inside the sill and onto the chassis rail.

I finished off with tape on the outside which strengthened the strips underneath

With the doors removed I took off the striker latches and taped them up along with holes left by removing the small soft top clip things. I tested pulling off the little rubber edge trim but they were well glued on so I carefully taped them up.

I have never seen my car so bare!

Here is how I left the front clam fixing part of the sill, should still be strong as most material was left, just a little moldy.

I forgot to take a picture of the fully sanded and taped sill before I put the clam back on, but happy I spent the extra time getting the tape where I wanted, so hopefully at the end you won’t be able to spot the colour change.