Due to my car originally being a lightweight Elise, the sheer panels fixed into the side of the longerons as opposed to the top like the Exiges. Because of this I planned to make hybrid sheer panels for the conversion, Elise fixing with Exige profile.

Before I sold my Elise clam, I made a very rough template which would hopefully give me a base for my hybrid panels, including the fixing positions for the longerons and ECU. Unfortunately I didn’t have long to make the template as the buyer turned up to take the clam away very soon after I got it off the car.

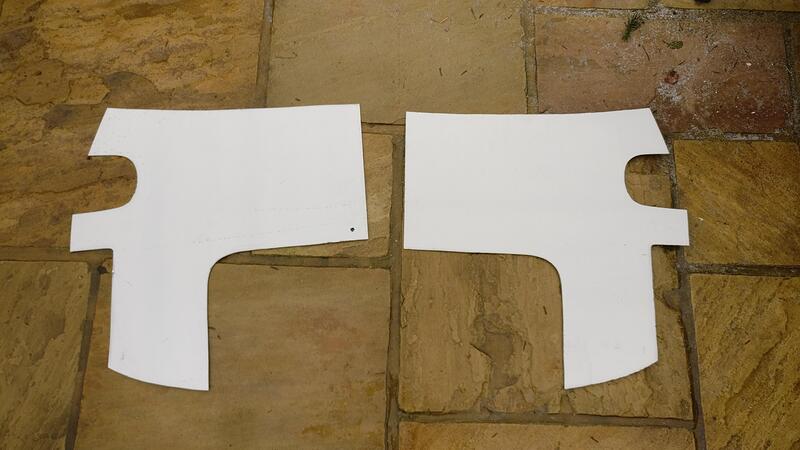

I transferred the patchy template onto a cleaner sheet of cardboard and went for a test fit.

The test fit went well, but I had overlooked the position of the rear spoiler supports, which obviously weren’t on the Elise. This would need amending and a few other areas too.

To stop water, stones and other crap building up against the sheer panel (which happened on my Elise) I left a gap at the bottom by the drainage hole. Hopefully this allows water to carry the small stones and dirt out as there’s only so much the wheelarch liners keep out. Below is how much crap was stuck in just one side of my Elise clam, most of which should fall out the bottom of my Exige clam.

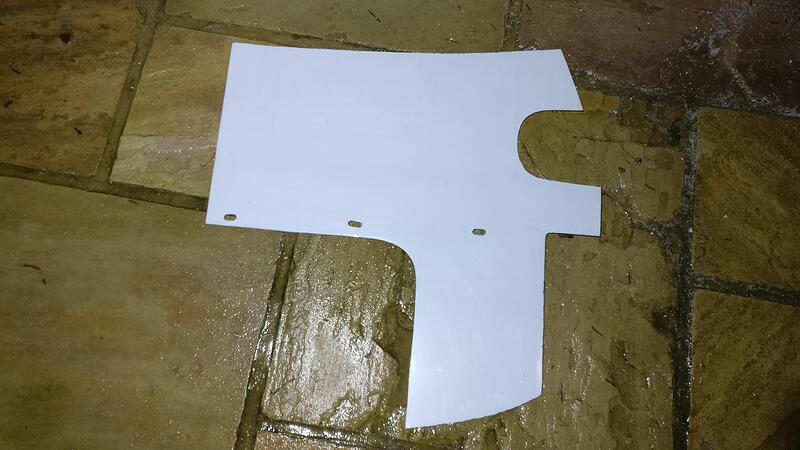

More crude cardboard was cut and stuck until I was happy with my final version of the template. I left a hole by the lights to allow me access to the indicators without the need for taking the wheelarch liners out and also the loom to pass down to the fog and reverse lights.

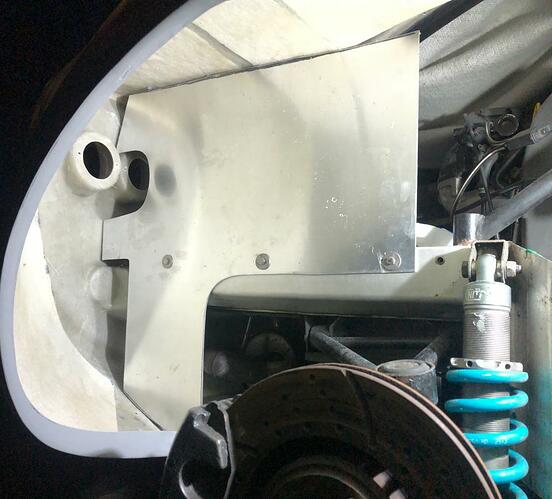

I transferred the outline onto a 2mm sheet of aluminum. I could have gone thinner, 1.2mm was probably the OEM thickness but once I realised it was too late. I enquired about returning it but I’d have to pay a re-stock charge, so stuck with 2mm.

I had to buy a jigsaw to cut the sheets, good tool to have so didn’t mind. The panels were easy to cut out, I left a bit extra where the panels meet the clam to give myself a bit of adjustment room if needed. I then took some files, sand paper and a sanding block to smooth off the edges.

I didn’t have many tools available to make the fixing holes. I took a small drill bit to get some pilot holes before moving to a larger drill bit which cut the outer edges of the rectangular holes. Once these were drilled the holes were just big enough for the jigsaw blade to fit though, this got rid of most of the material in the middle. I then took some needle files to get rid of the extra middle material and finish the edges. They’re not the neatest but as long as they’re in the right place that’s all that matters.

A final test fit and I am happy with the position and shape. I still need to drill the holes for the spoiler brackets, but rather than fixing or bonding the rest of the sheer panels to the clam I am going to use rubber edge trim where the panels meet the clam to wedge it all together. This will not only ‘seal’ and act as the bonding to the clam, but the rubber should act as a good insulator against any vibrations should there be any.