Tell 'em you have a Porsche. They’ll be around like flies on sh1te ![]()

Fixed that for you Tim ![]()

I do agree though,…especially EVO mag, they’ve gone a bit mental on the Pork.

Can I suggest our little seen member ChevronB37as a possible writer?

He’s shaping up as a journo with online and print articles. Plus, he is the custodian of The83Man’s Exige.

Good idea! He certainly has some talent.

Anyways back on topic…come on Pat I bet you’ve not spent the weekend sitting on your arse, g’is an all update then eh ![]()

I certainly have not ![]()

Ok so next test was to run the car upto temperature, managed to do a 30minute fast idle. Checking temperatures and pressures via the software all the while:

Engine develops a very healthly 6.8bar cold idle oil pressure, dropping to around 3.2bar hot idle. Got the rad hot, both fans came on, but coolant stablised about 85degC, oil about 100degC. This was in about 5degC ambient so I expect the car would probably overheat if I had to idle/crawl in traffic on a hot summer’s day for an extended period but I’ll try to avoid doing any such thing ![]()

At the mo it’s running very rich, I’m awaiting an expensive NTK wideband to begin sorting that out.

Uncovered a slight oil leak from one of the scavenge hoses, but noting major and good to find it now and not later when on the rollers.

I also swapped out the mechanical fuel pressor gauge for the Bosch fuel pressure sensor I’m going to be using and now need to calibrate that.

Next job is to do a full oil change as the engine was sat for so long before it was in my possesion I’m wary of it being a little dusty. A full oil flush now, and another after mapping will give me peace of mind ![]()

Once that’s done I’ll try and run it up again, hopefully with a few more revs and throttle this time. Then work on transient fuelling (blips) with no load (stationary) then it will be rolling road time so we can map with load on the car.

Hopefully more progress later in the week…

cheers,

Pat

Fantastic Pat,…looks like you’re still on a trajectory that will see the car out to play at Anglesey ![]()

I bet your neighbours love you eh as you conduct your 30min fast-idle test. Just wait until you get to the transient fuelling tests and you’re there all day blipping the throttle ![]()

More vids when you get a chance…

Updates: (apologies nothing picture-worthy)

Fixed oil leak, oil change done.

0-10bar fuel pressure sensor fitted in place of mechanical gauge. Sensor calibrated and work started on closed loop PID program. (but I think this will take a while).

All temperature sensors calibrated as best as possible (all within 5degC of true temp and 8degC of each other which is pretty good. Coming from an OEM background you’d be surprised on the production tolerances on all OEM temp sensors!). Sensible ignition and fuel compensation tables for water and air temperatures and battery voltage inputted as starting points.

Had it upto 4500rpm so far. It got a lot louder ![]() (it’s not actually that loud at idle). It will respond happily enough on a gentle throttle but won’t blip still yet as fuel pressure isn’t stable enough, and there is still no transient fuel or ignition in the map. Don’t really fancy taking it up much higher revs-wise until we get to the RR with a nice big fan and proper AFR measurement in place.

(it’s not actually that loud at idle). It will respond happily enough on a gentle throttle but won’t blip still yet as fuel pressure isn’t stable enough, and there is still no transient fuel or ignition in the map. Don’t really fancy taking it up much higher revs-wise until we get to the RR with a nice big fan and proper AFR measurement in place.

Confirmed that the alternator works ok, but the biggest problem at the moment is not being able to the back the EWP off when it’s not needed. Running it flat out at idle is overkill and is also more than the alternator can handle. For some reason the EWP isn’t responding to the PWM signal from ECU in the way that it should so I either need to try another Pierburg EWP (suspect mine may be faulty) or possibly in the short term fit a bigger alternator…

Still working hard on it! More soon

cheers,

Patrick

Good work! Enjoying this, although much of it is unfathomable to me . . .

I seriously hope that the next few weeks go smoothly Pat and we get to hear that V8 ringing out as you pound up the hill towards Rocket ![]()

![]()

One month to go Pat, give us all an update and your current feeling as to whether you going to make it…

Would be just to see it !

It’s not looking good! I have to pull the gearbox again to swap the propshaft… ![]() apparently Ferrari accidently through-hardened them all and it appears the standard ones fail at will!

apparently Ferrari accidently through-hardened them all and it appears the standard ones fail at will!

F355 GTS Propeller Shaft Snapped Clean Off!!!!!!

http://www.fcars.co.uk/forum/showthread.php?14645-355-Flywheel-Free-wheeling

Pretty gutted. The only silver lining is I don’t think the engine has to come out. Still I suppose if this was easy everyone would be doing it.

Annoying as I had just provisionally booked a rolling road session for Wednesday 9th March. If that had gone well I think I might have made it!!

Ben, will advertise my Anglesey spot on the thread unless you know of anyone who’s already expressed an interest?

Sorry for the bad news, I had the engine blipping nicely as well!! ![]()

Nooooooo ![]()

You not tempted by a Caterham CDX rental car Pat?

There’s already a waiting list for the event Pat so if you do decide you can’t make it at all then contact BAT.

Like you say if it was easy…

Keep us up to date, when the shakedown is scheduled I really hope to be there!!

if you need someone to take the anglesey space I know a man

Update time!

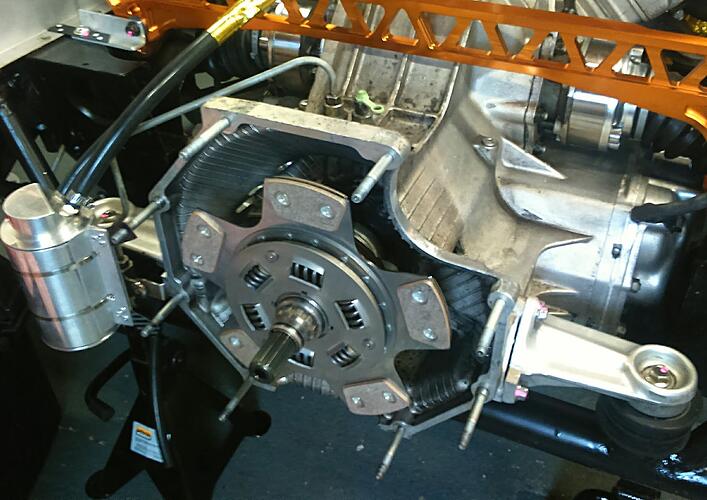

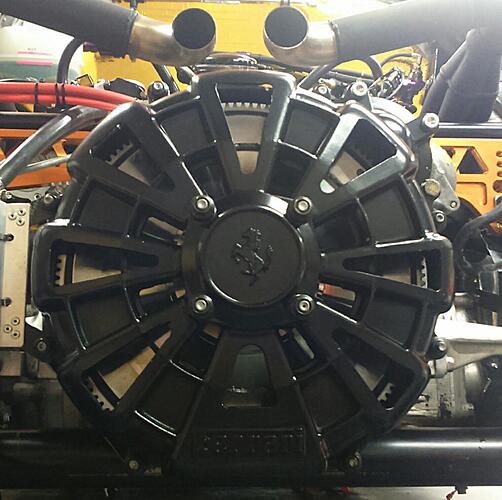

So while fixing the broken shaft I addressed another area I’d identified for improvement on the car - the clutch and flywheel.

As standard the F355 ran a dual mass flywheel. The two elements inside the DMF are torsionally damped by some sprung elements, but also by a special Kluber grease. The cars are notorious for problems when the grease has either liquified from a gearbox oil leak from the ‘triple seal’ on the transfer shaft, or solidified through absorption of dust and other debris.

In order to avoid these issues on my 2nd hand 'box (and because I spotted room for a very significant weight saving) I decided to switch to a traditional single mass, lightened flywheel, with a sprung-centre paddle clutch (the standard F355 friction plate is not sprung as it is assumed the DMF does all the torsional damping).

I also swapped out the F355 solid transfer shaft for one from the Ferrari 348 which is gundrilled from both ends and 30% lighter.

The flywheel and clutch were provided by MD Clutches. The flywheel is completely custom and nearly 50% lighter. The sprung clutch is adapted from a Ferrari 360 unit.

The pressure plate and all the clutch release gubbins are carried over, and I swapped in some Ti bolts for added intertia savings on the pressure plate.

The total weight savings are 4.8kg a saving of 27% on the total clutch & flywheel assembly.

I also put some work into the clutch cover. I’m becoming pretty blasé to taking an angle grinder to Ferrari components now, which I’m not sure is a good thing!

Anyway another 250g saved and I’m very pleased with how it came out. ![]()

Overall 5050 grams saved. 4800 of them rotating mass, and all of them hung out behind the rear axle!

Hope to be back on track for final mapping soon.

cheers,

Pat

Great work Pat ![]()

I am really enjoying following this thread ![]()

great work on the clutch assembly!

Yup fantastic work. Keep us up to date Pat, once it’s ready for exercise I really hope to see it. Spa in July would be ideal no ![]()

Amazing.