Have a look at this: http://ferotus.blogspot.co.uk/ - just seen on Seloc: there’s lots of discussion about it on the chat section there.

It’s looking like a nice build, be interesting to see how it turns out.

It is truly fantastic work and a great build blog. It really is gonna be something exceptionally special!

I’d already been in contact with Pat and suggested Anglesey might be an ideal shakedown venue if the car is ready ![]()

Hello all,

I did try to sign up on here around a year ago, but the registration system defeated me!! Ben’s message reminded me to try again with success this time. ![]()

Thanks for the comments. Yes the car is 95% physically complete now but there is still a lot to do on engine set-up and mapping from scratch.

I’m also planning on running some reasonably sophisticated, ECU-controlled strategies for engine ancillaries, which I know will take a reasonable amount of rolling-road and track time to optimise. (closed loop fuel pump control, 2x PWM controlled fans, PWM controlled electric coolant pump).

Nevertheless I am going to push to try and get the car out for Anglesey if at all possible so hopefully I can meet a few of you there!

cheers,

Pat

Hi and welcome Pat, great that you’ve joined…what about a few build pics on here to give people an idea of what you’ve done?

Friend of mine has a 355 which sounds great at high revs.

Huge welcome to exiges.com Pat! Thanks to Sean for sorting out Pat’s login.

We’re all looking forward to Anglesey but the prospect of that V8 in that car being wrung out on the way up to a Rocket,…wow just wow. Gonna be lots of very special vehicles at Anglesey this year,…can’t wait!

Ok so 18 months of hard graft crammed into a couple of posts for anyone who hasn’t been following the blog:

May 2014 - Cat D (light clam damage only) 1999 Elise purchased.

2 days later:

Didn’t originally set out to buy a F355 engine, but couldn’t turn this one down! Found it on ebay ![]()

Spent about 7-10 days working out how to fit it transversely. Was planning on using a 2009 Focus RS gearbox.

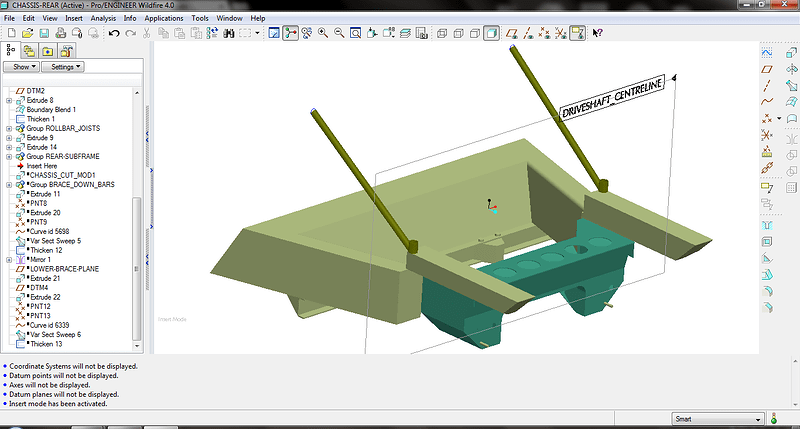

CAD’d up the engine and engine bay in a couple of evenings. (I have about 4000+ hours on ProEngineer)

Realised the measurements weren’t stacking up. So bought the bullet and got the angle grinder out. Knowing in the back of my mind that the car could be better as a result (lighter, much lower, more central CoG)

Bought a matching F355 manual transaxle:

Fast forward 3 months (Dec 2015), rear structure is re-braced and engine mounts complete:

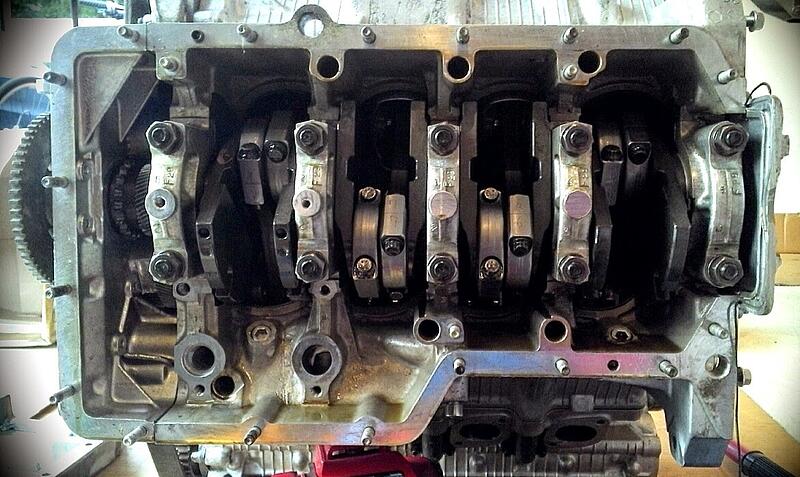

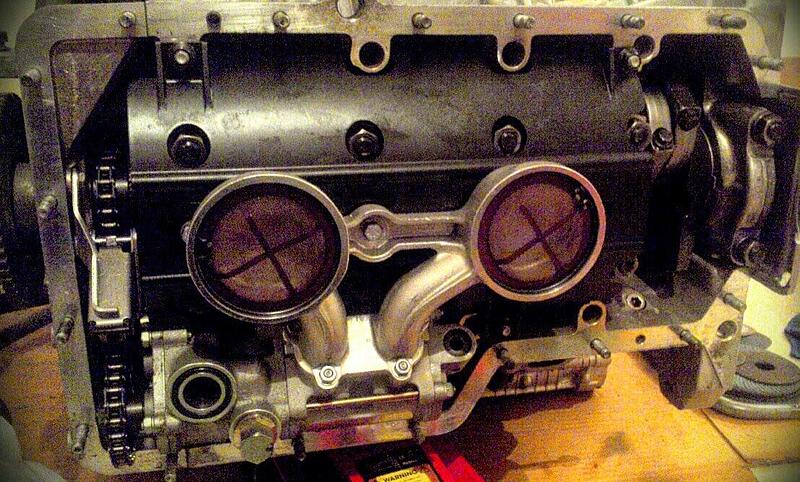

Rebuilt the F355 oil pump and checked inside for peace of mind:

going to have leave it there for tonight, more tomorrow!

Awesome Pat, following with much interest. Can’t wait to see and hear it once its all done. The gear lever setup is awesome!!!

I don’t go on SELOC, but no doubt all of the arm chair engineers are nit picking the crap out of your car. Tell them bollox and stick to Exiges.com

Hope to meet you at Anglesey.

yeah welcome, looks an awesome project!

Welcome Pat one of the best sounding engines ![]()

Welcome Pat, that looks like a fantastic project, look forward to seeing the progress ![]()

so where were we?

Built a bulkhead. Fitted engine.

E92 M3 manifolds:

became a perfectly suited, lightweight and exactly equal length custom exhaust system:

this:

became this:

became this: (and fitted perfectly first time!)

Gearlinkage was built. This was not a straightforward task but the end results are very satisfying.

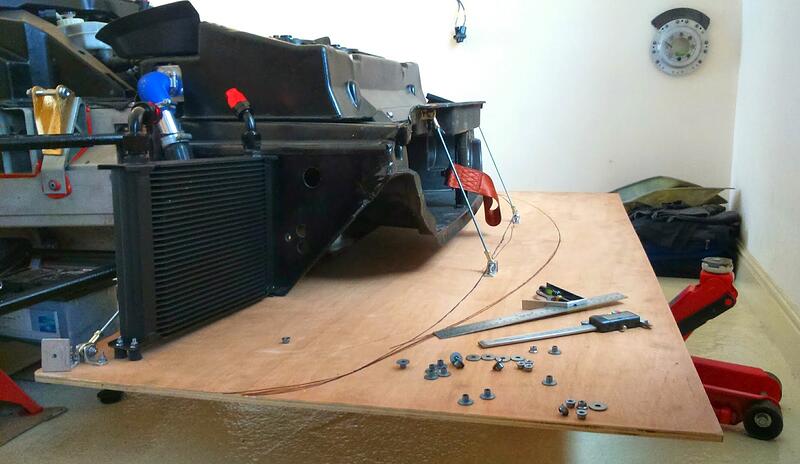

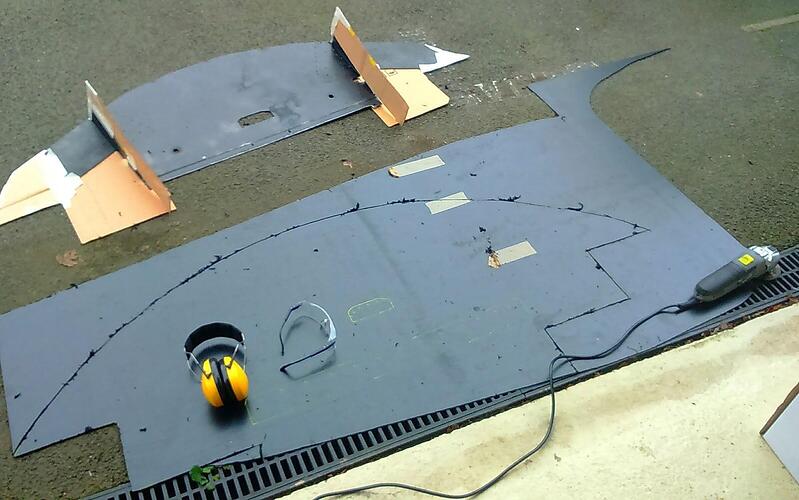

Built a splitter:

Bolted on a rather large wing… Tooled up my own polycarbonate S1 engine hatch (I will post more on this later)

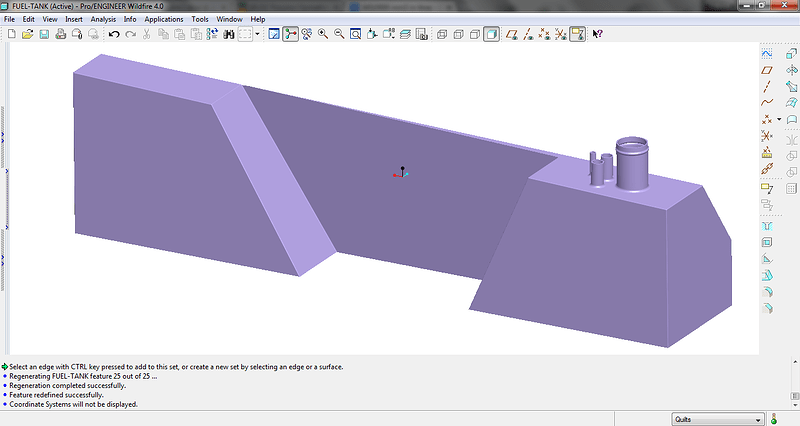

Wrapped the car orange, bolted on all the easy stuff like EP bush kit, pilbeam-design lower rear wishbones, EP S2 race uprights, EP throttle linkage, Freno Carbon brakes, Nitron NTRs, quick rack, snap off steering wheel, Reverie driver’s chair. Comissioned custom driveshafts. Designed custom dry-sump oil tank. Plumbed in 56mm core all Ali rad and a large oil cooler. Pared down the standard wiring loom. Wired custom screen demist solution and replaced toggle switches. Fitted a plumbed in fire suppression system.

Now you’re upto date. At the moment I’m just finishing off a diffuser:

That’s the last 18 months massively condensed down into a couple of posts. I’m sure there are probably some bits I’ve missed so if you have any Q’s fire away!! I have completed all the work myself with the exception of welding aluminium fuel tank, welding aluminium dry sump tank, welding the exhaust manifolds and wiring the Engine & Comms loom that Ryan is doing for me.

Pre-empting the most obvious questions:

1) …about 400bhp

2) …somewhere under 800kg

3) …120dB?

![]()

Fuel economy? ![]()

Looks fantastic Pat, I have been following. Would be mega to see you and the car at Anglesea ![]()

WHAT …A…CAR!!!

Might do the same to mine next weekend ![]()

Bonkers brilliant.

Absolutely fantastic Pat, keep up the good work ![]()

Utterly awesome… I’m completely in awe of the engineering something like this takes. 120dB ?! - hope you get chance to use it!

I think you should stop being a girl Pat and aim for more than 120db!!! ![]()

Thanks for the comments guys!

Not really sure how loud it will be. I am planning on a motorcycle style removeable dB killer if need be for certain trackdays.

Hopefully receiving the last bits of loom this weekend, so fingers are crossed for first attempt to start the engine next week. Very excited! ![]()

That must be understatement of the year! After all the hard toil I’d imagine the first time you hear that starter-motor whir and you awaken the beast…wow that is gonna be dancing around the garage territory ![]()

How much fuel did you get into that tank? And did you baffle it?

How much did you extend the wheelbase? It looks like you pushed that engine as far forward as you possibly can…