Simply staggering! Can’t wait to see{and hear} it at Anglesey.

“Well done!” seems hardly adequate by way of congratulations

A nice way to improve a Ferrari ![]()

Fuel capacity is about 37 Litres (yet to measure exactly). The tank has an internal collector with one-way ball valves.

I haven’t extended wheelbase or bodywork at all. Just standard S1 Elise/Exige geometry apart from the EliseParts S2 uprights…

cheers

Popped over to my local scrap yard today to pick up a 355 engine & box…sold out…bloody useless! ![]()

Nice to see something different from the usual conversions. Stunning workmanship!!

![]() funny

funny

In anger, my Cup260 only gets 8-miles/gallon… will that 37-liters get you 100-miles range?

Very cool project though… I wish I had the recourse to do something like that.

Lookss like a Lotus…Sounds like a Ferrari …Utopia.

Amazing build quality …can I borrow you for a few weeks to redo my rebuild?

well done. Cant wait for the start up video.

Just awesome ! looks like a top quality job .

Indeed … Superb engineering.

Who’s gonna trump this ??

Moomin , how’s about squeezing one of your F1 V10’s into your S2 ??

I know you have a few of em ![]()

Slowly coming to life! ![]()

Fitted the remainder of Ryan’s hard work at the weekend. It all fell into place really nicely which means A) I did a reasonable job measuring up and B) he got it all spot on to the diagram I made. Had it cranking over though the proper loom now (had previously had it cranking but only on jump battery)

Next step will be running through testing and & calibrating sensors once I have full comms with ECU (waiting for a piece of Cosworth software)

cheers,

Pat

Probably a bit impractical mate with the pit crew that would have to follow you to start it ![]()

Full 9 hour day spent on Friday with a friend of mine who does engine calibration in F1 and two laptops and we got pretty close!! ![]()

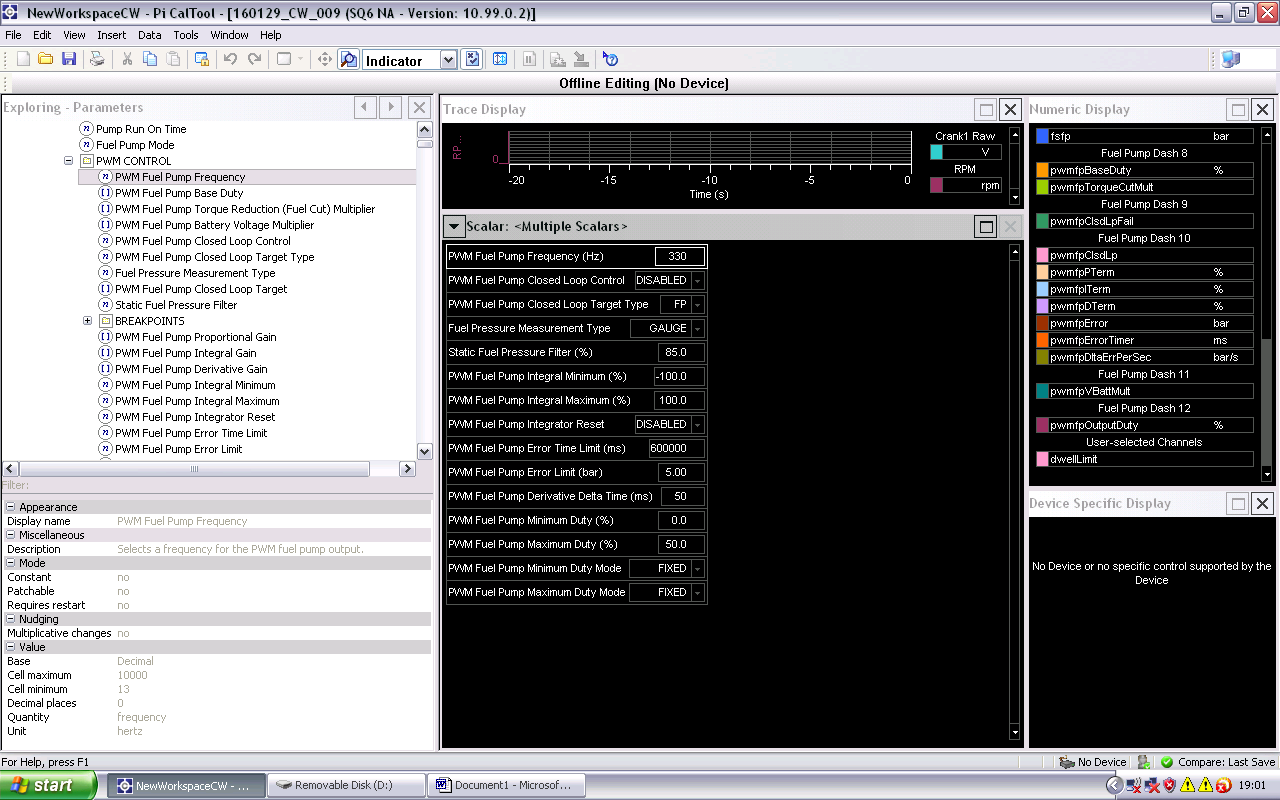

All sensors now calibrated bar fuel pressure. However we did successfully get the PWM control of the fuel pump working which was one of my big worries as I’m sort of treading a new path in the way that I’m running that so it was a big relief to hear the pump run up to pressure as it should.

We have base fuel and ignition maps set up for cranking and idle, and all the fuels compensations input for the whole map which will save rolling road time later.

We got cranking and a good solid trace from the cam sensor. However getting a funny trace from the crank sensor which I’m 99% sure is due to pins being mixed up. Without this we got no SYNC and therefore no spark or fuel but we are very close now ![]()

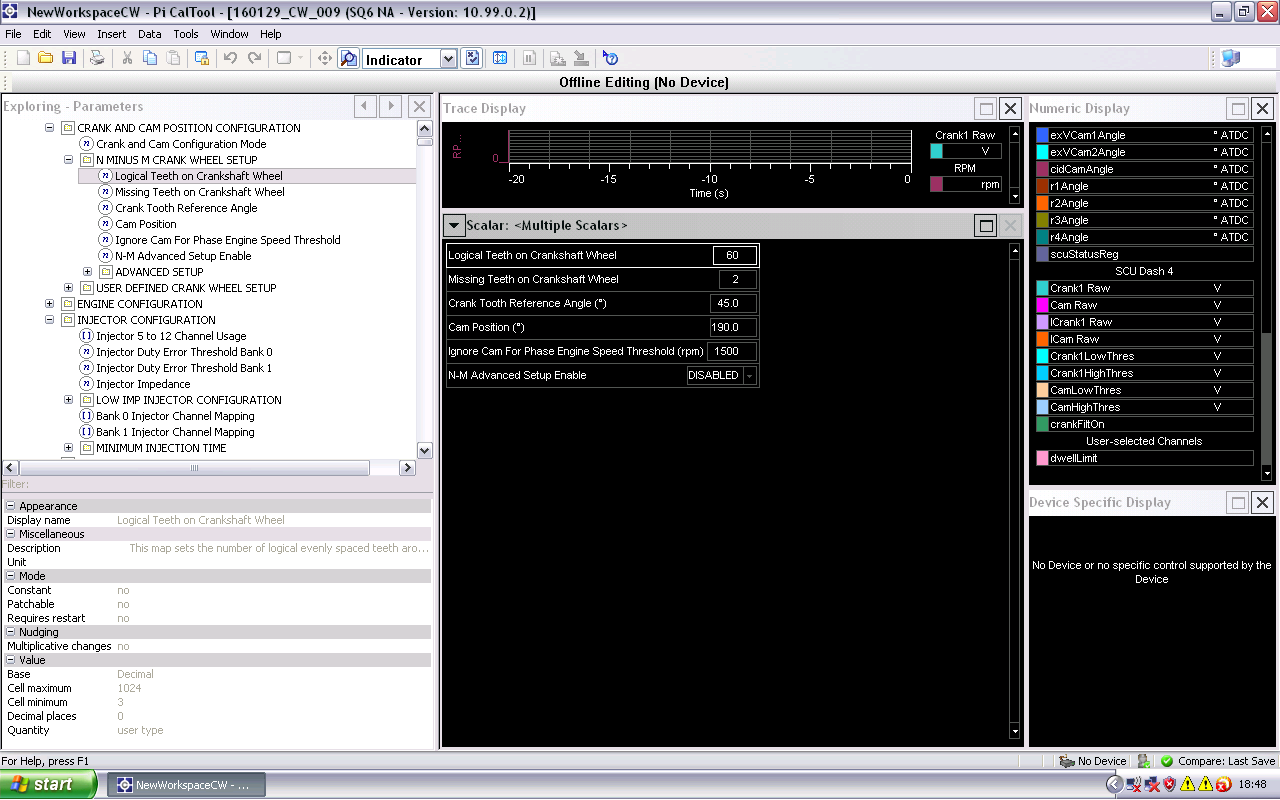

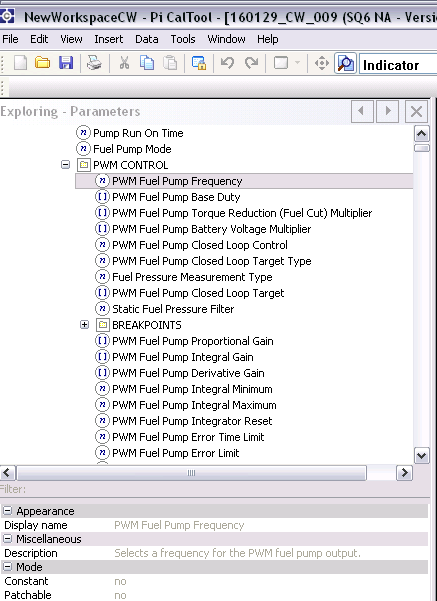

Here’s a couple of screengrabs showing what we’re working with and lots of the options for closed loop, PID fuel pressure control in Pi CalTool…

I dont understand anything shown on the screen grabs but keep up the good work. I hope its ready for Anglesey as it will be epic seeing this do a few laps.

Yeah keep going Pat looks like you’re making great progress!!

Astounding, the technical capability of some people.

On tenterhooks waiting for next instalment

IT LIVES!!!

Is it for sale?

IT LIVES!!!

Great news Pat, hope you get to Anglesey so can see and hear it ![]()

Well done!

I didn’t understand the screen shot either but worried about the ‘number of teeth missing on the crankshaft =2’ bit!!