have a look at the life PDU and panels, no brainer when you have their / syvecs ECU

You’re right, completely forgot to look at Life/Syvecs. Do like the look of the Cosworth one though!

Some forms of motorsport switches rule over membrains i.e bumpy terrain or is drivers eyeliner must remain fixed forward and little time to look at membrain to make sure you are push the correct button. I.e hill climb or sprint events or high speed levels of motorpsort.

i usually put my eyeliner on before the start ![]()

Know what you mean, this is predominantly a tidy up of non-essential wiring so dash mounted panel should be fine. What is or is not needed can be discussed but right now the wiring needs tidying and simplfying.

Haha bloody predictive text phones.

Bumpy terrain ![]()

Haha, classic ![]()

Your car just gets better and better Chris. Its fantastic that you’ve really taken on the continued development of the car, or to put it another way,…take on a car that’s had a load of money thrown at it and throw a load more money at it ![]()

![]()

Put simply i enjoy doing it!

Its driven me mad with failures, wasted track sessions, endless researching, cost of parts etc but i’d do all over again because when it works its an awesome little car!

Yup many of us can relate to that and we all love reading about the car’s development on this thread.

Roll on 2016!!

Cheers Ben ![]()

Anyone know if the TTS Engine mount kit moves the engine significantly backwards and if running a Quaife would be an issue with it?

Will try to make contact with Darren to ask the question directly…

depends on who’s mounts your coming from, also you need to consider the rotation too

Thanks Tim ![]()

After much deliberation we’ve decided to stay with the setup we have and not try to move the engine back which will give us even more problems to solve.

CPS Drivelink are going to copy the uprated shaft so we have a spare, its one they made anyway, and they’re going to take the CV Joints back that they made and make new cages for them out of 300m, the same material the shafts are made from. Basically make the joint as strong as possible and have one complete spare shaft with joints ready to pop in. Lead time about 4/5 weeks.

Lets hope along with the better grease, breathers, stiffer springs, higher ride height and more solid rear end it helps towards solving the CV joint issues.

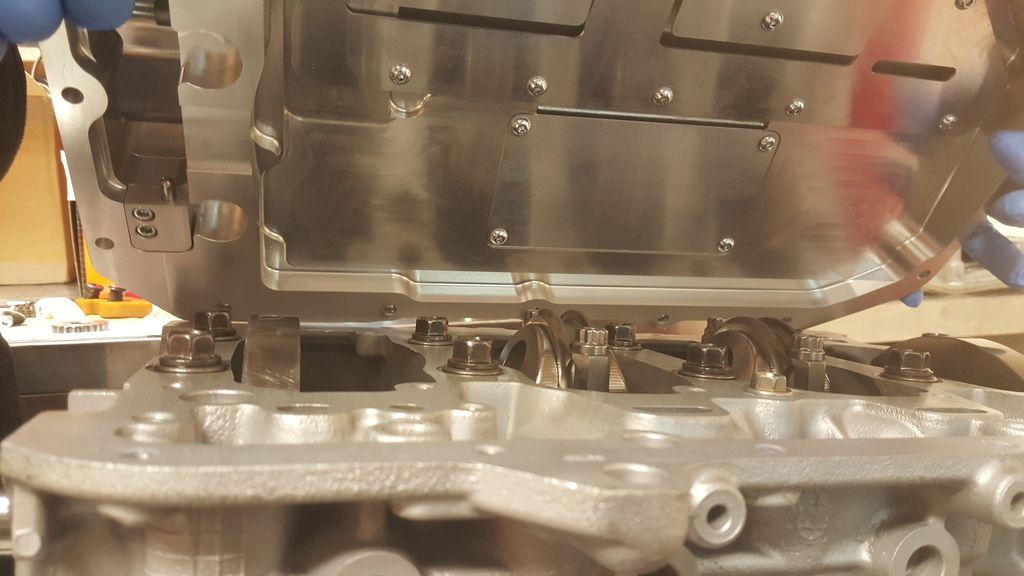

New engine was collected from TDi-North today…

New AT Power Dry Sump pan is also attached…

Did have a problem initially though, the K20 Dry Sump is designed for a standard crank and with mine having a beefier stroker crank it was catching on the sump and wouldn’t turn…

Neil (TDi-North) marked off what was needed to be taken off…

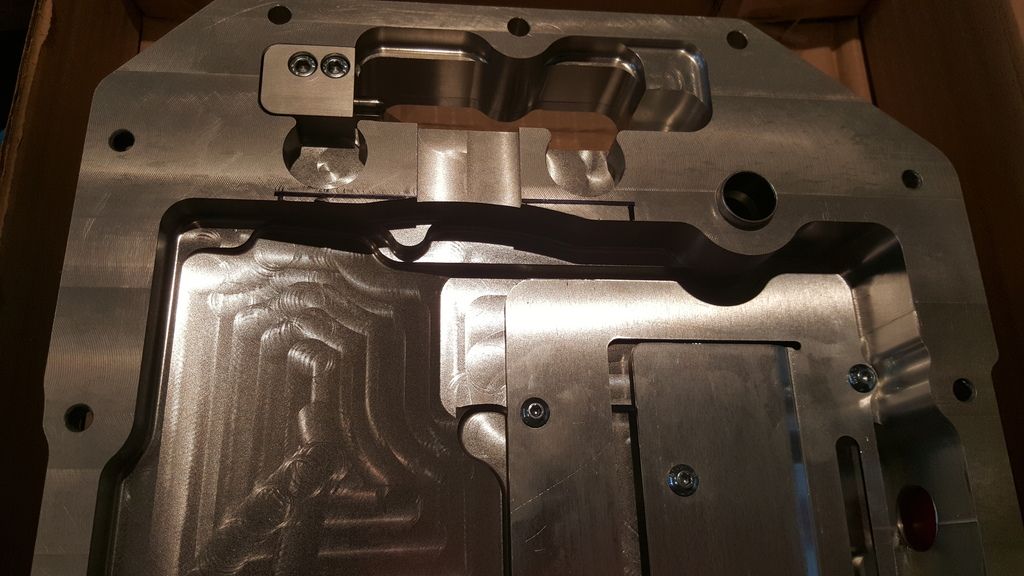

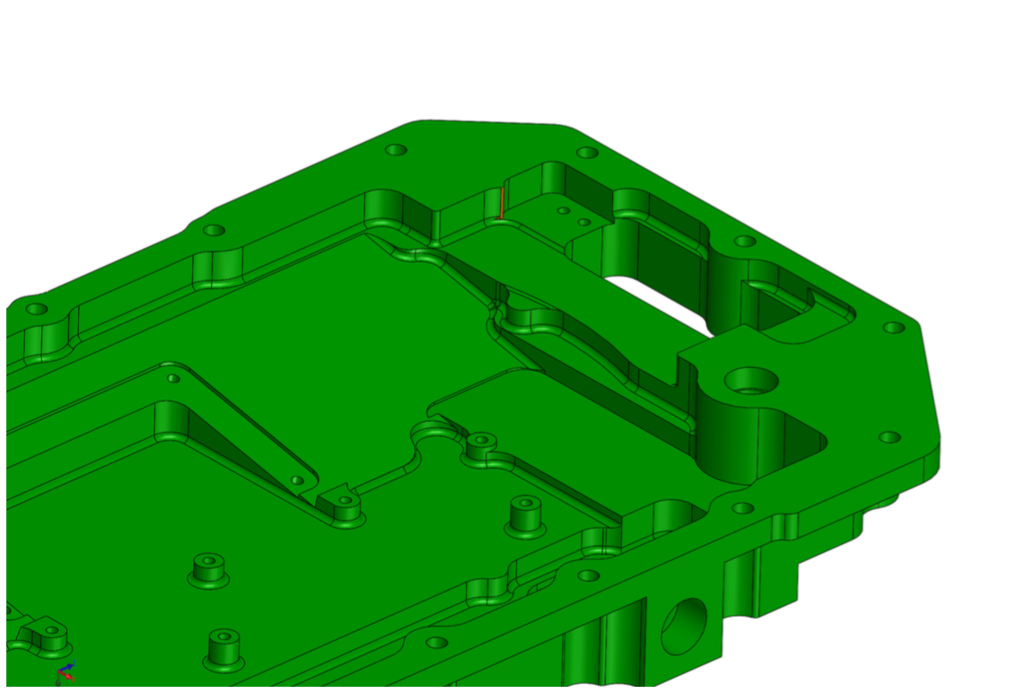

As it happened the K24 Sump design which caters for raised bearing caps has this area removed…

AT Power kindly took the sump back, CNC’d it and got it back to TDI-North in 3 days ![]()

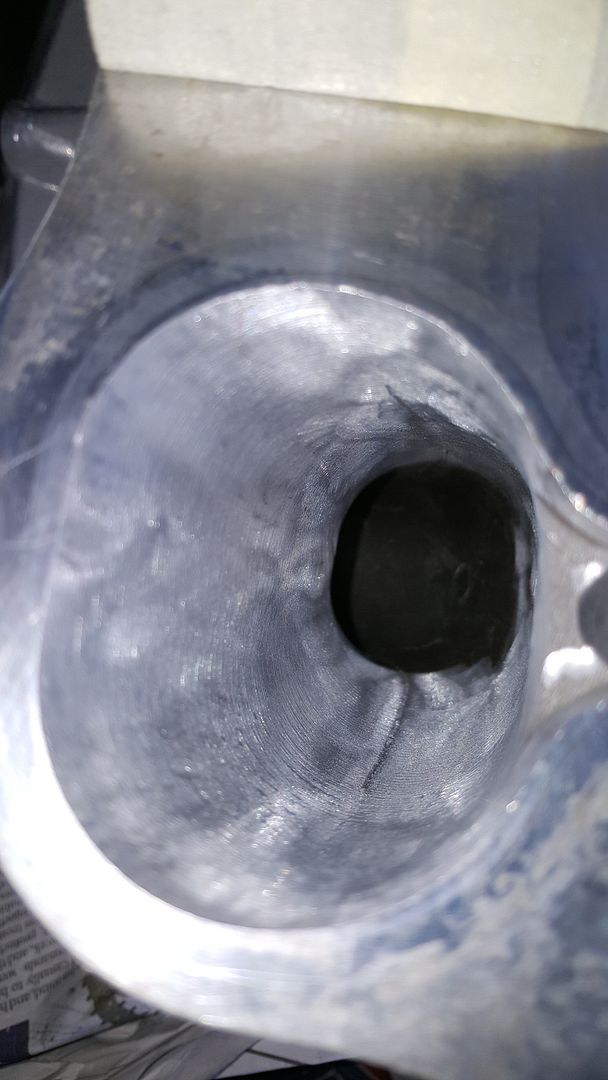

Heads have also been done, Clockwise CW2 Cams, Supertech valvetrain, ARP headbolts, Toda cam chain and tensioner, ported and polished…

Time to get it fitted and finish this thing!!

a loverly spec!

I like your head. A lot!

Cheers lads ![]()

TDi spec’d the heads to suit the bottom end, they also ported the manifold so together it should flow well…

Dropping engine off on Monday, sump lines and tank also need installing, exhaust needs sorting then hopefully Dyno January!

That looks like a proper motor that. Hopefully lots of reliability found for 2016 eh Chris. Looking forwards to seeing the car on circuit next year ![]()

where is it being mapped?

Ben, it has worked well using both Clockwise & TDi-North, having these 2 advising on a Honda build is a good place to start from. I’m not worried about the engine reliability it’s more what the extra torque is going to do, revealing the next weakness or firing up old reliability issues. I’m ‘only’ aiming for 400 bhp but then again look at the problems i’ve had at 300!

One thing i’ve learned is that 300 bhp in these cars is quick and thats with me being nowhere near as good as some of the drivers on here and having had relatively little seat time. The plan is to try and strike a balance between what we could get power-wise and what will make it reliable so i’ve bought a 4 port boost solenoid just in case we need to reign it in a little to protect the Gearbox, Shafts etc from the possible torque levels in certain gears.

Tim, Romain Lévesque will be mapping, hopefully at TDI-North (Warrington) if Paul is OK with that, seeing as though they built the engine and have a Dyno in house it makes sense (plus its near me!). Its always nice to get a car mapped somewhere that specialises in your particular car or engine, there’s always a chance if something fails they might have it to hand and not blow the session. As ever i’ll share all information from the mapping session, good or bad, but if you fancy popping along you’re more than welcome and will tell you when.

Good on you Chris, pushing the boundaries and really developing the car. Its gonna be quite something with the new motor installed ![]()

In other news, will we be treated to something that looks a bit like this at Anglesey ![]()