TE Relay ![]()

[quote]Originally posted by deltav

small update tonight…Car is back in the workshop and the stripdown has begun to sort some of the new mods we want to do.

floor pans off and up on axelstands

arch liners out, front splitter off,

New rear wing is here. a quick size comparison…

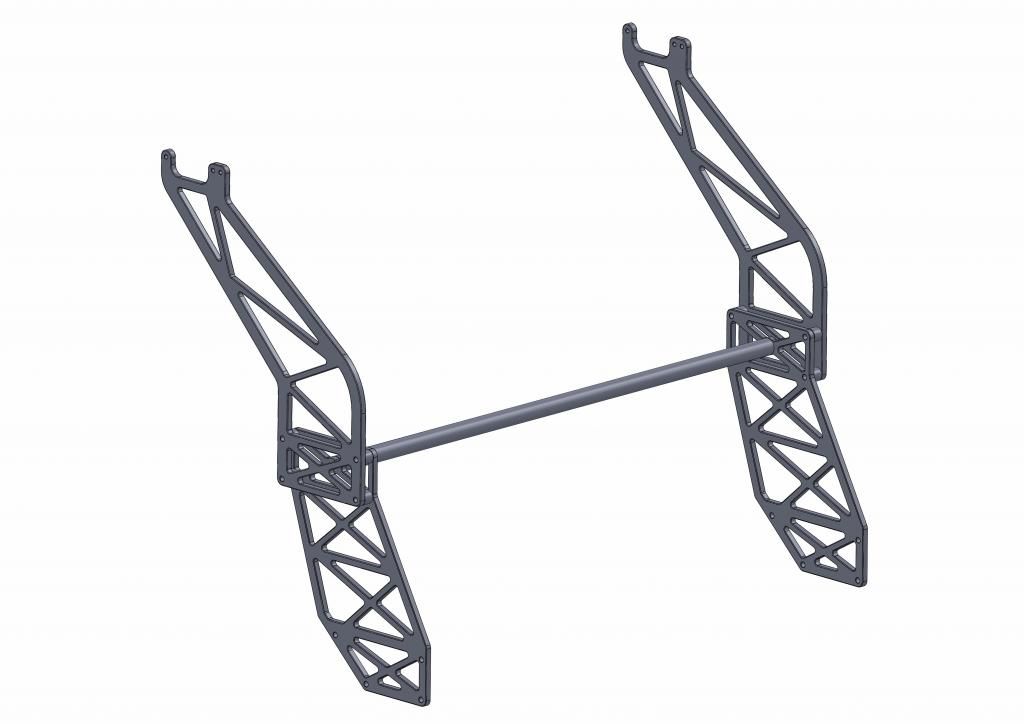

Also managed to sit down tonight and draw up the proper wing mounting brackets

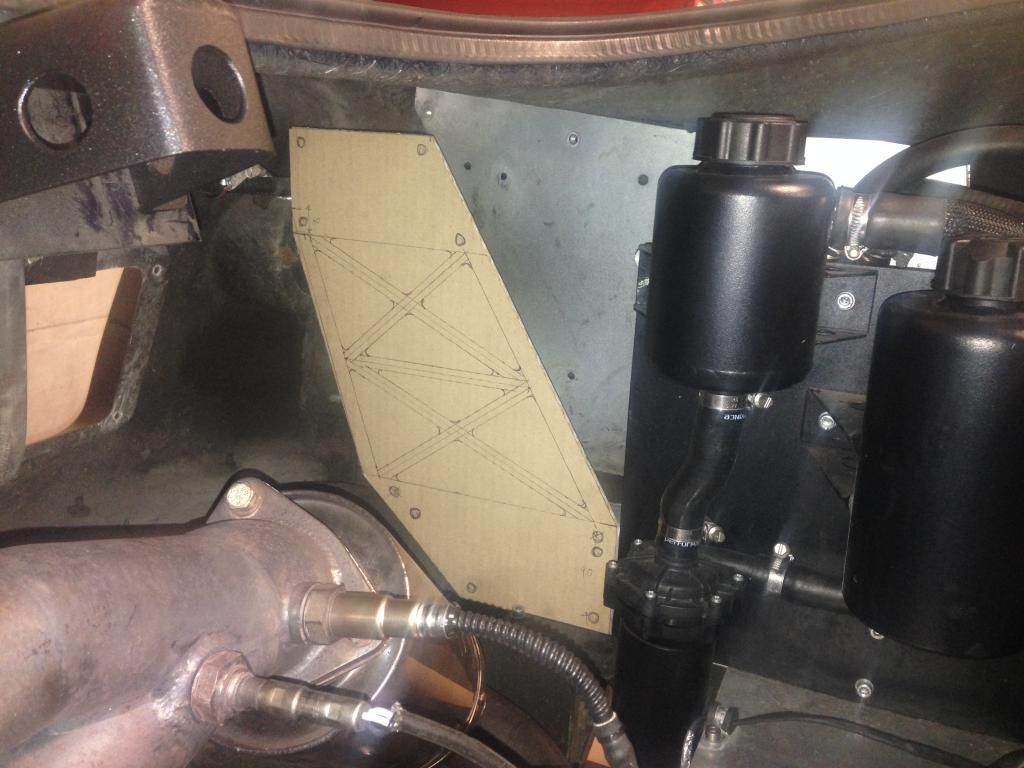

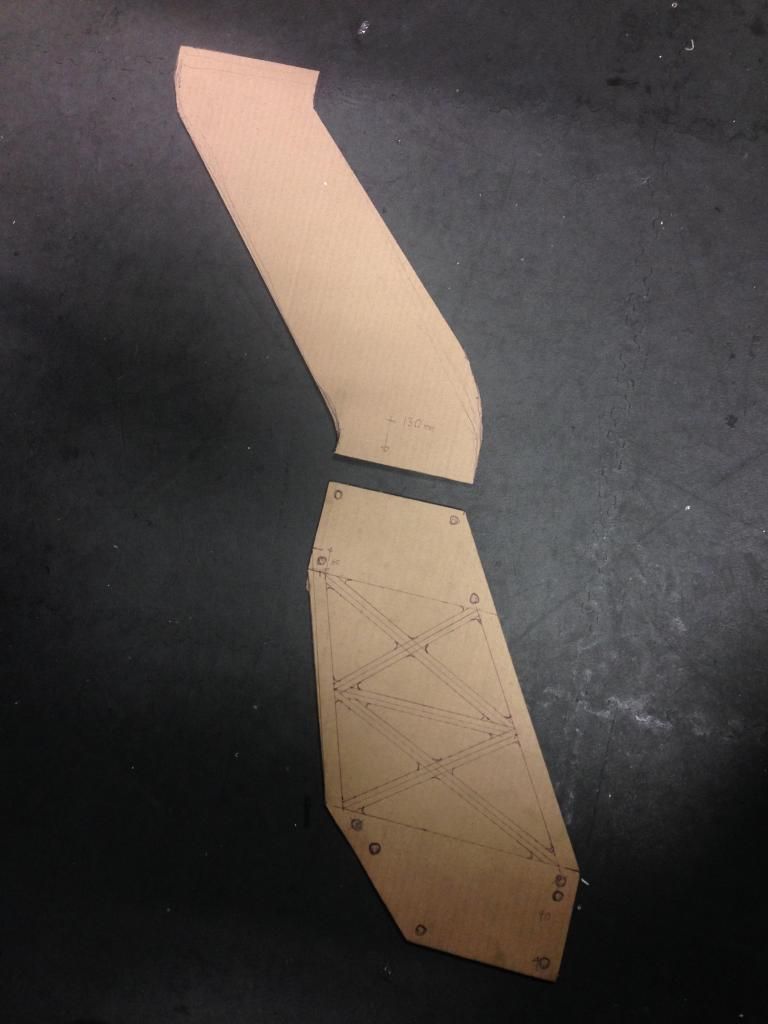

Made some mockup templates for the new spoiler brackets… going to make them in 2 pieces so that the clam can be removed quite easily by leaving the main lower bracket boleted into the main chassis box.

shocks all removed and stripped down,

old softer springs and the harder ones we will be replacing them with

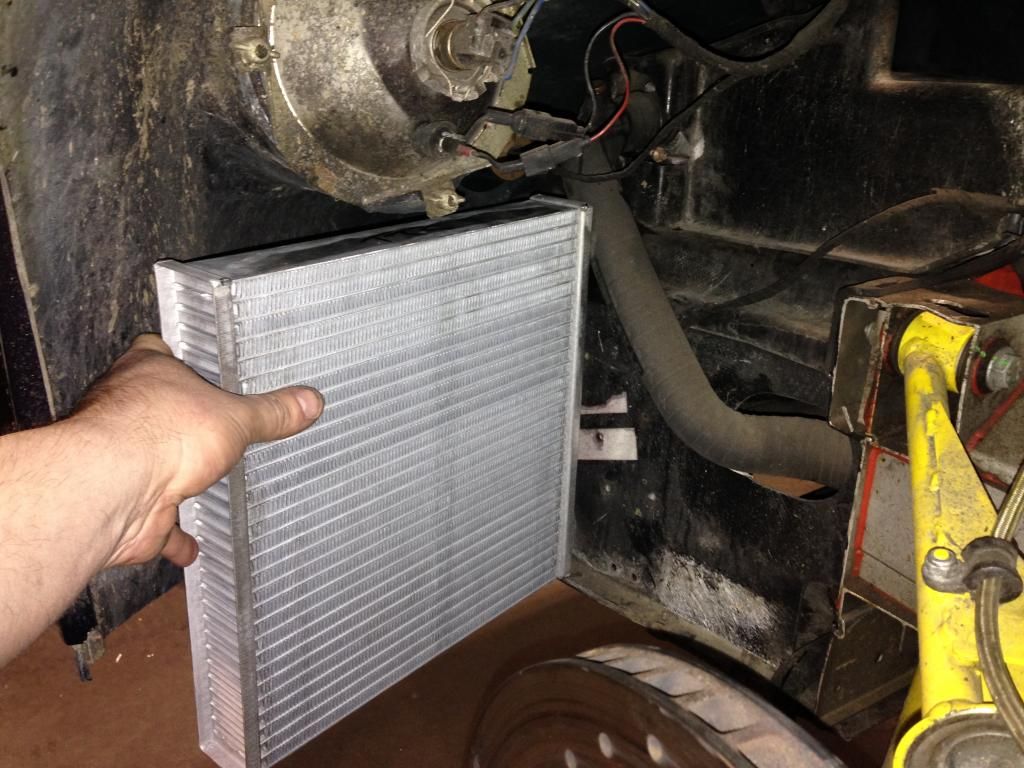

Had a bit of a poke around with the new charge cooler pre rads. all looks pretty straight forward to mount and run the pipework so will get into this at the weekend.

And finally we have a new BOV to go on, changing out the 40mm recirc forge supersize for one of there new 50mm atmospheric valves. this is mainly to cut down on noise as the recircs make a hell of a noise when your just blowing them off to atmosphere!

Just made some 2 part pylons myself for the same reason, need a good polish and anodising (Badger Anodising in Bham). Mine don’t look as high as yours nor do they look so far over the rear of the car but you may want to add a secondary brace hole on the upper mount above the clam. Maybe an 8 or 10mm hole just incase you do get a slight movement… I did on my one piece last year, tiny amount but enough to make me do it again. Anyway they are not fitted yet, bottom part is braced like Gav’s and the top part is Titanium rod, 8mm, 10mm if I need to…very possibly.

I actuallt had a good chat with del at DJ racecars about the brackets. He normally advises running 6082 T6 brackets at 6mm thick, However due to the distance and height as you say we are actually going to run 10mm thick 6082 brackets to aid side to side flex, It is best if possible to get away without braces directly under the wing as you don’t want to disrupt the airflow underneath the wing profile if possible.

Oh and they will be machined with 4mm corner rads on each side so the air is not hitting such a blunt object

Right then…quite a lot achieved today really.

New front splitter has been made…

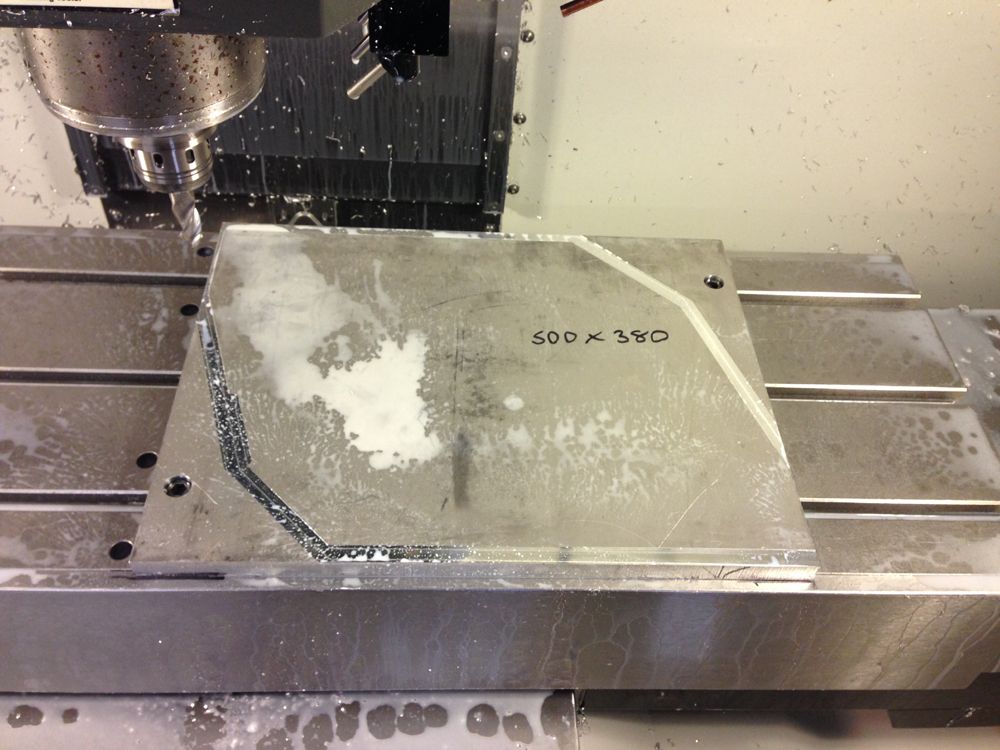

Had to stick it in the old bridgeport to machine the back edge down a little so the thicker sheet would slide over the rivnuts in the chassis.

We mocked up the wing brackets with some 2mm sheet. I got told this looked stupid and I needed to change it before something got thrown at me. lol,

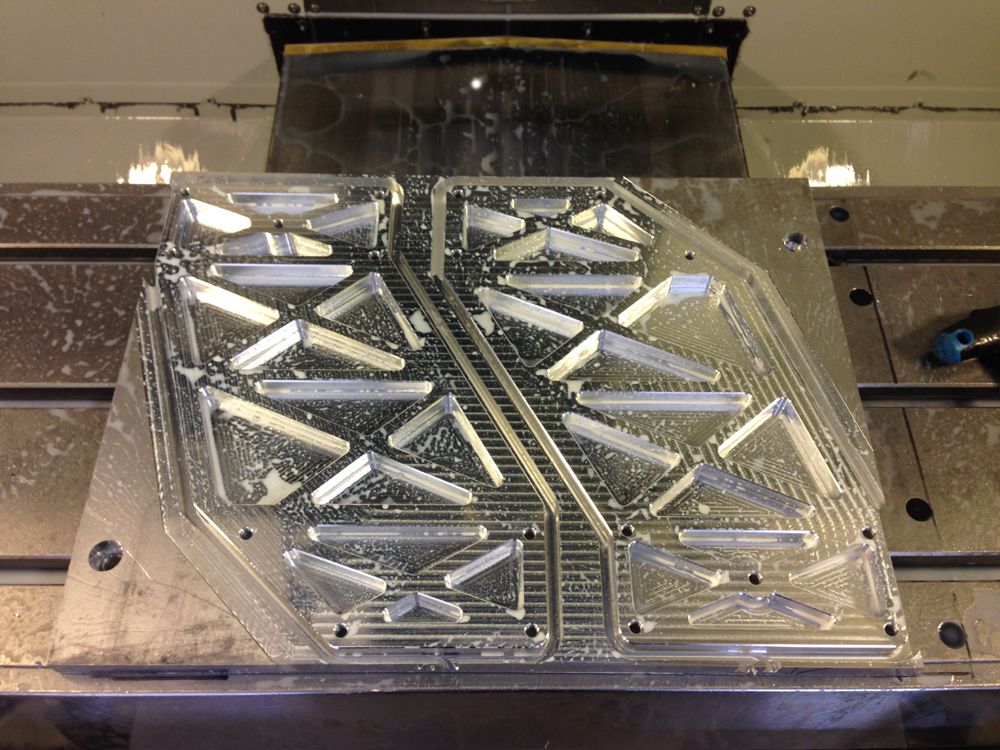

So I made some mods and dropped it 60mm and moved it forward 50 just to make it a little more sensible for the road. Then we hit the cnc ![]()

Have put a 4mm rad on the outside edges to to help the air get around the brackets a bit as they are 10mm thick. Also need to glass up the old slots in the clam from the old wing, will do this when the clam comes back off next week.

Then marc started making a mess by cutting out the new vent slots in the front wings…

I will bond the mesh into these next week

Also today lots of things done that you cant see. New battery isolator wired in, oil and filter change, some shims needed changing on the suspension, split boot on a trackrod end etc etc,

Then last job for the day was to remove the re-circ valve from the charge cooler and weld on the new 50mm external Forge BOV.

Excellent ![]()

Love the wing pylons, but bit shocked by the splitter and canards, they look lethal.

Looking good!!

Splitter will have a rubber trim on the leading edge once powder coated, and I insisted that the canards be removable, only for TD use.

Seems a shame to cover that up with bodywork ![]()

Why the offset on the pylons rather than straight?

It’s because the wing isn’t built for an exige so the brackets aren’t in the right place, and if mounted off the outer side of the chassis rails then taking the clam off would be a right ball ache as I would have to cut and modify all the standard clam brackets down onto the chassis.

An elegant solution, then.