Moving onto the disc brakes, I remembered that the rust on them really stood out against the black of the wheels and looked crap. For the finished car I wanted to stay away from this as best I could.

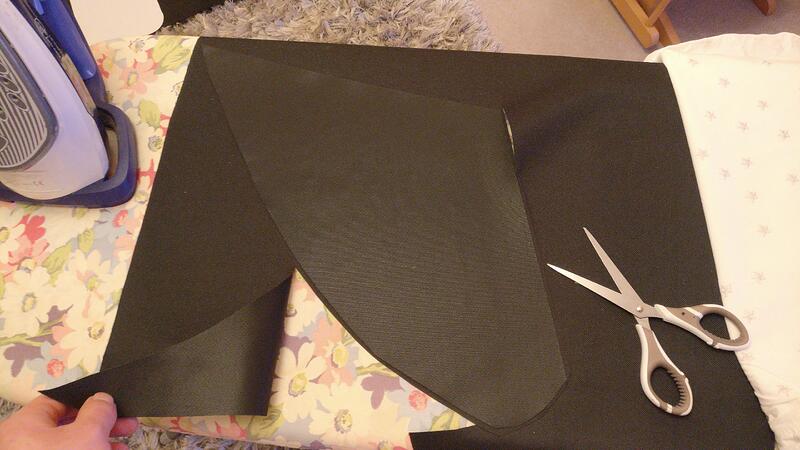

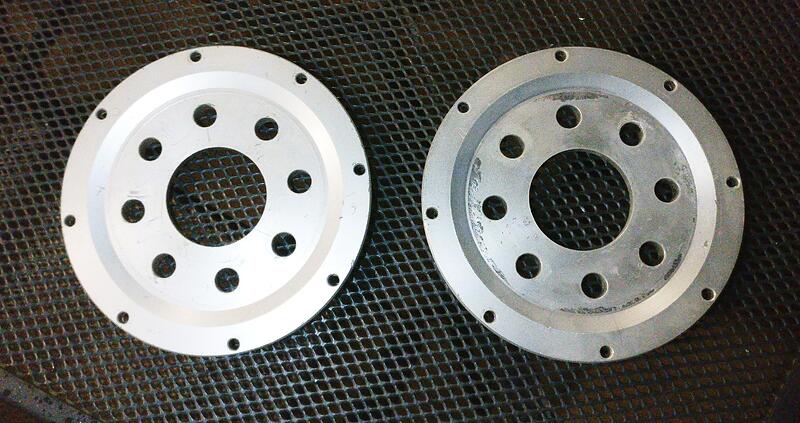

Generally the ally belled discs were in good condition, but I felt I could improve them.

I needed to separate them, so took out the bolts and tried to push the bells out. Unfortunately they were stuck solid, so I used a block of wood and a hammer and shocked them out.

All separate and ready to have some work done.

The bells were pretty grubby, but I didn’t want them to stay silver as I felt they would stand out too much against the black wheels.

I cleaned them up and got them ready to paint.

I felt it was important to keep the mating surfaces free of paint, so I masked these areas off.

As I’ve said before I don’t like shiny stuff inside wheels and like to hide things as best as I can, so I bought some matte black paint. Due to the high temperatures the bells and discs will go through I bought some stove and BBQ paint.

I gave the bells a few light coats of the paint, sanding afterwards to get a nice flat surface ready for the final coat.

Here are the finished bells, the paint isn’t very durable so will have to see how they hold up.

I to the discs now, where I wanted to clean up the surface rust. The AP Racing discs aren’t too bad, but the fully cast ones have been on the car a while so have a fair coating of rust on them.

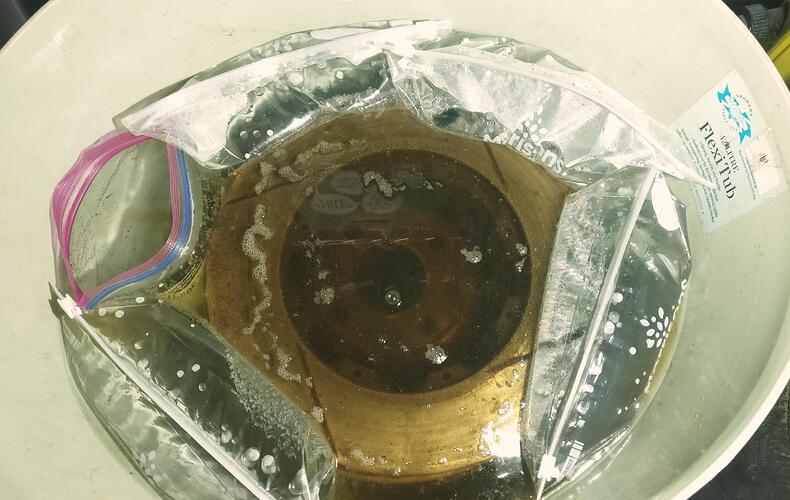

I found a thread that said vinegar cleans up rust safely, so I bought a couple of cheap bottles to give it a go.

I got a large bucket and placed a few small wooden blocks in the bottom. I used these wooden blocks to separate the discs so the vinegar would be able to penetrate all surfaces.

I placed the blocks on the contact areas for the pads so any rust that wouldn’t be penetrated wouldn’t be an issue as it would clean up under general driving.

All stacked ready for the vinegar.

Unfortunately the vinegar didn’t quite cover the 6 discs, but I had an idea.

I filled sandwich bags up with water and places them around the discs. This displaced the vinegar more and meant the discs were them fully covered, and being in sealed sandwich bags the water didn’t dilute the vinegar solution.

I had also read to add some salt to help speed up the process, so bought some super cheap table salt and scattered it into the solution and gave it a stir.

After only a few hours the water was turning rusty so I knew it was working.

Unfortunately, the day after I was told to get the car ready to go to the bodyshop, so I had to take the 4 fully cast discs out and put onto the car. I left the 2 AP Racing discs in the solution for another 3-4 days. The solution was definitely filled with rust after the 4 days.

I kept the solution to use for the cast discs once the car is out the bodyshop and will follow the same process as a what follows here. I’ll post some pictures of them finished shortly.

I took the discs out and scrubbed them with wire brushes to remove as much of the loose rust as I could, changing the water for fresh occasionally.

Once the discs were as clean as I could get them I used some sodium bicarbonate to neutralise the solution on the discs in some clean warm water.

I would have liked to have left the discs with this appearance, however they would only rust again so I decided to paint them to match the bells.

After the bicarbonate bath I dried them as quickly as I could with a towel and a hair dryer and then taped up the pad contact patch. I had to move fast to avoid as much fresh rust build up as possible. You can see in the first pictures the rust was already starting to build again.

Due to the fast moving pace the spraying was pretty rubbish and was runny in some places, but I managed to cover all exposed areas and inside the vanes with the matt black paint to match the bells.

I then left the discs for 24hrs next to the boiler to cure.

I then gently tapped the bells back onto the discs, being careful not to chip the paint.

I bought some new AP Racing bolts as safety components aren’t worth the risk to reuse.

I gently tapped the bolts through and used tape to mark which ones I had torqued. I torqued each bolt to 14nm.

Here are the completed front discs. After torquing and removing the tape I found a bit of paint had made it’s way onto the pad contact surface, probably because I was rushing and put a few layers on too thick. On one disc I thought I would sand the paint off, but then realised it would probably be easier to just put an old set of pads in and go for a quick drive to remove the paint.

I am half tempted to spray the bolts if I have any paint left after spraying the fully cast discs, if not I think they won’t stand out too much.

![]()

![]()

![]()

![]()