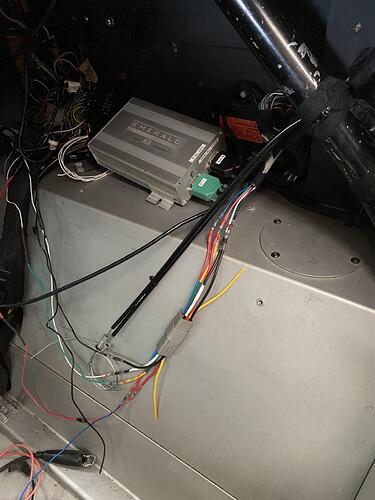

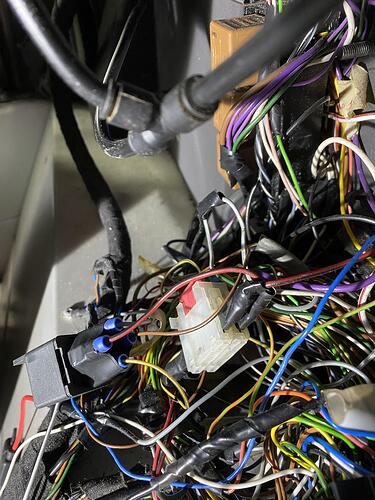

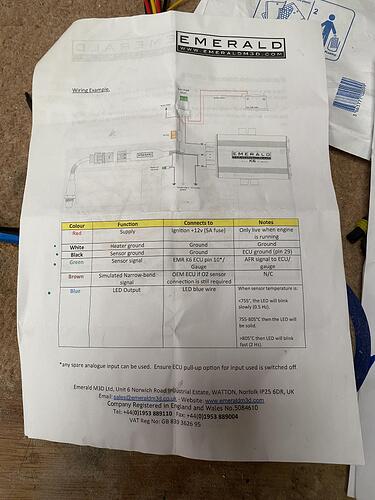

Managed to find some time to wire in the wideband to test that it all worked before tackling the loom mess and unfortunately it didn’t. The little LED that is supposed to light up was not.

I check my wiring again. Still nothing. Contacted Emerald and was told yep the LED should light up. So took just the LED off and put it across a battery and sure enough it worked. Hmmm.

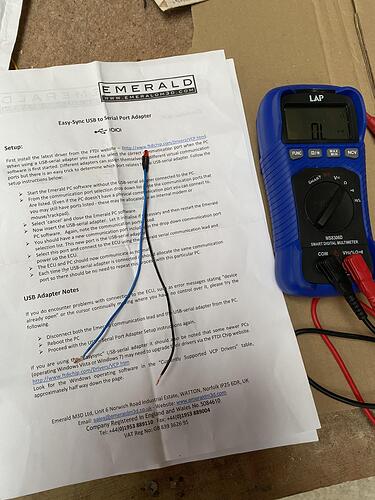

I checked the feed to the LED and it is a constant 2v which to me seems a little odd as the LED is supposed to blink when the lambda is cold (I’m not that confident here but surely the signal to the LED should pulse?) I will need to call Emerald again.

I put tools down and went for a coffee to think.

Suddenly had a thought - the main feed to the wideband controller comes from the fuel pump relay (T off the main feed to the fuel pump), this is as per Emeralds wiring diagram.

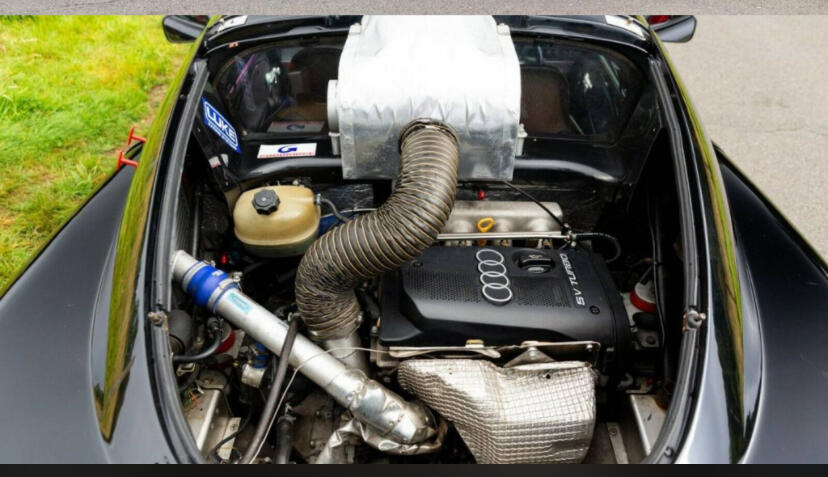

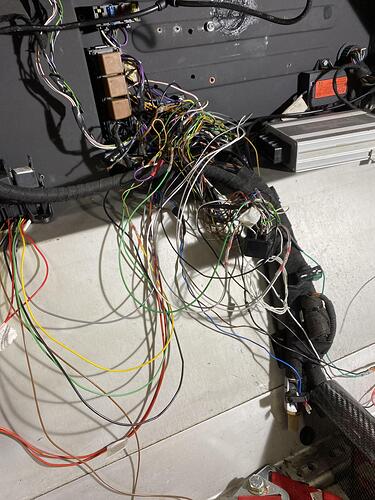

On the Audi conversion there is a second in line high pressure fuel pump so decided to check and sure enough the wire I have connected into goes to the positive feed to the secondary fuel pump.

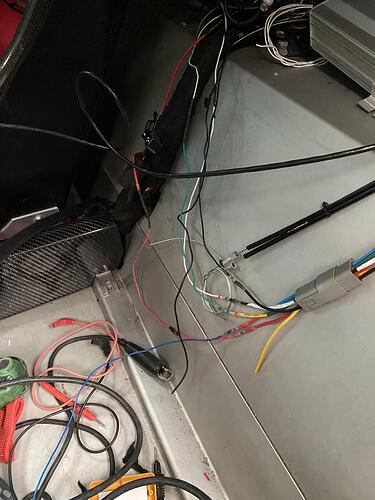

Then for some reason whilst the engine was running and I was thinking, I touched the fuel pump relay to see if perhaps there were loose wires and I found that the connector on the relay which feeds both the secondary fuel pump and my newly wired in wideband lambda was getting hot. Hmmm

Not the relay itself, just the terminal and connector. Ok usual thing is poor contact causing resistance. However the connection is tight and clean. Hmmmm

The had a thought - if there a short somewhere?

Cut off the feed to the lambda in case it was something I had done. So now the car was back to as it was before I started and sure enough fuel pump relay connection feed to the fuel pump still getting hot.

Next I checked if there was a short to earth with a multimeter and sure enough there was.

Touching the multimeter to the terminal on the fuel pump relay (which feeds the inline fuel pump)and to chassis earth. Done when the engine is not running and hence when the relay has not switched on the live feed). There is a direct feed to earth!!! Hmmmm

This is where my stupidity kicks in

So I think I have found something at least. So my thought process was “Yey, this is it, I’ve wired the lambda live feed into a bad fuel pump live feed and this is my root cause.

Next I take the fuel pump off and test it with a multimeter- sure enough across the terminals there is a direct connection. This is it I stupidly think.

New fuel pump ordered and tested before I fit it and oh!

It also has a direct connection across the terminals. Damn!

My next action was to walk off, lock the garage and try to forget about it for a while…

Any thoughts, insults or words of encouragement welcome