That’s a great feeling, somehow I never feel like I’m at that point until the final day of the project! Lack of planning on my part I guess…

Wow I hate working on cars sometimes. I was busy making small progress, the new driving spot lamps and brackets went on, I did the indicators clip repairs, I managed to get the ac pipe off with heat and a dremel to carefully split the nut.

Then putting the new pipe on I wrecked the new condenser. A spanner was promptly thrown across the garage. Basically I didn’t hold the nut well enough on the condenser side so it twisted and sheared off the connection. seriouslylotus will be getting another order from me to replace it again! Another half day plus to take the entire thing apart and replace it again too.

Before you splash out on a new condenser, can you notget it alloy welded back on ? Its only a radiator after all ?

Unfortunately not, I did a proper job of it. Took

90 minutes to strip it all apart again this afternoon. Then spent a while cleaning things up in the wheel arches to make myself feel better.

Ooof that stings. I came extremely close to doing the exact same, I felt it going and just “caught it” with a bit more pressure on the “static” spanner.

They really are delicate, the whole system is really.

Here you can see the broken indicator clip. Offside was like this already and the nearside one broke while removing it

Cut off the remains and filed back

Measured up to drill the hole and rivet the new clip on

Not too bad a job, in all it took probably less than 10 minutes per side.

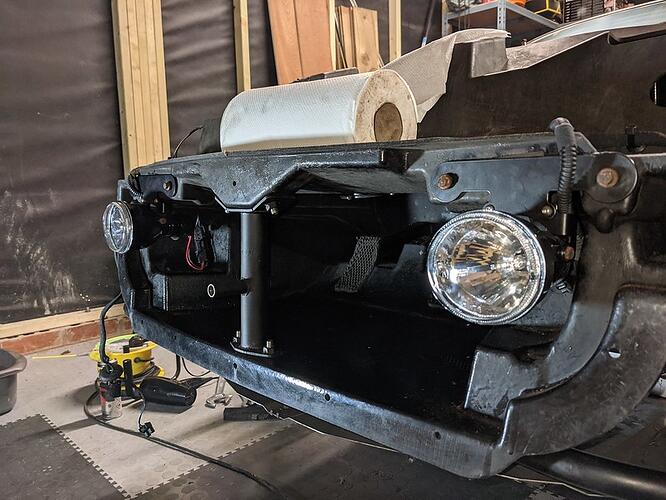

New lamps and brackets fitted - after checking photos from some of your builds on here I’ve since found out the wiring routing on mine isn’t right so I’ve redone it now.

I’ve stripped all the rad pack off the car again and while I’m waiting for the new (new) condenser I did a quick bit of cleaning of the chassis etc in the front.

Looking good Andy, I still need to do a bit of magic sponging on my chassis… tedious but quite satisfying.

New New condenser arrived during the week, went out to the garage for the afternoon today and started putting everything back together for the second time.

I managed to get the ac lines connected up this time without damage, hopefully they are OK. I got the new drier in, that wasn’t too bad. All the wiring loom is in place again, the oil lines connected back to the coolers etc.

I think the next step is to back fill the oil coolers until oil comes out the bleed nipple at the oil filter sandwich plate. That means getting the rear in the air and the undertray off.

Then I’ll refill the coolant and fire up to bleed and check for leaks. Found a mobile ac guy who will hopefully be coming end of next week to test the system so need it all buttoned up by then.

No need to fill oil coolers just top up oil a little and start engine it self bleeds. Give the engine a warm up stop and check oil and top up if needed.

I swear this car is trolling me right now. I was busy bleeding the coolant when I knocked off the front hose bleed screw from the perch I left it on. It fell into the front compartment and disappeared down a tiny hole to never be seen again underneath the hvac unit.

Good ideas to procure a replacement are welcomed while I go and kick something.

Top work. First time I realised I needed new indicator brackets, was on the M1 at 70mph (honest) , when the nearside indicator ended up on the rad grill.

Not sure what to do yet. Apparently discovery td5 bleed screws might work, I ordered one cheap from ebay on the off chance but I need the car running before the ac guy visits on Thursday and the screw probably isn’t going to arrive in time. I might have to order new silicone replacement pipes from eliseparts tomorrow on next day delivery.

I tried to retrieve the screw for ages, even fabricating a suction retrieval device with a Henry hoover and garden hose stuck down the hole but with zero visibility its just blind fishing.

If you just need the car running before the ‘proper’ plastic screw arrives, can you just bodge it? Stick a proper bolt in with the correct head - washer or flange head preferably and maybe tape it up for good measure? You might not even have the car running long enough to open the thermostat anyway if you’re just pressure testing the AC system.

Bit late now, but the screw doesn’t even need to come out when bleeding - just undo it a little bit and the air/coolant can bubble out.

Yes, I’ve found a bolt and an o ring which looks like it might work. Will test after work tonight.

I tested after dinner last night in sub zero temperatures. It was pretty hard to get the car up to temp out there! My replacement bolt sort of worked, in that it worked initially but eventually the o-ring wasn’t enough to help seal the flanged bolt head against the pipe and it started to seep coolant out once the system was fully pressurised.

I have a plan now though, whatever happens this will be enough to help me get the AC system testing done this week. I’ll wait for the LR bleed screw to arrive later this week and see if that works. If not I’ll order the silicon pipes from Eliseparts for the weekend and be done with it.

That sounds familiar! Trying to bleed the coolant system when you can barely make it to 80degrees in the first place ![]()

Small update, the air con guy came out and pressure tested the system, no leaks. Vacuumed and filled the system with gas/oil and everything worked as it should. That’s the good news.

The bad news is he thought the pressure on the return line to the compressor was low (10psi he expected about 20). Possibly due to blockages, maybe the expansion valve needs replacing, can that be done with clam on? He said the concern would be if not enough oil got back to lubricate the compressor. He still thought it’d be OK to use in normal road driving though.

To replace the expansion valve the clam can stay on but the system needs to be drained of gas

AC celebration was premature, went out a few hours later and nothing now, compressor won’t clutch in like it did this morning. Could it have lost all the gas so fast? It held pressure with the nitrogen pressure test this morning. I’ve also just put in the elise parts order for the rad pipes to fit this weekend, the Land Rover bleed screw was probably OK until I over tightened it. One disaster after another right now. Hard to do comprehensive AC tests and checks until I button up the cooling system properly because as soon as the stat opens I have a small coolant loss problem!

Wjen you engage the system does the radiator fans start ? Revs slightly rise ?