Afternoon all.

I thought I’d start a thread about a new project which we’ve spent the last 8 months or so trying to get going. It came about due to my Time Attack car needing a proper Honda K20 dry sump system and no current off-the-shelf systems being quite what we wanted. Mainly due to packaging reasons. Therefore we approached AT Power, a UK company who are starting to specialise in a new wave of dry sump systems and who have plenty of previous experience with the Honda K20. In fact, they already make a normal style K20 dry sump system. Added to this, they also have the benefit of being able to produce their own pumps.

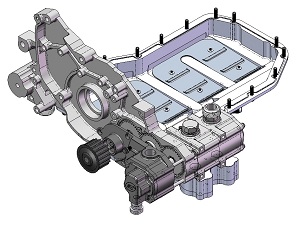

So, rather than following the norm this new K20/K24 concept involves driving the pump internally, therefore ending the need for the crank/pump pulley and drive belt. With this in mind it also seemed appropriate that the pump should be mounted directly onto the sump pan with the scavenge ports running through the pan itself and directly into the pump. This removes the need for so much pipe work/fittings under the pan and should also reduce potential leak paths, whilst at the same time saving on plumbing costs.

It’s planned for the system to use four stages. One for the pressure stage, two for scavenging from the pan itself and another scavenging internally, directly from the head.

There will also be provision for a turbo oil drain, by building a feed into one of the scavenge galleries.

Pressure/return ports will be positioned to allow for the shortest possible pipe runs (i.e intake/gearbox side)

Turbo drain/scavenge port machined into pan.

Built-in adjustable pressure relief/valve.

So, a few details about the pumps themselves:- (Final pump spec/flow rate/gearing to be finalised after testing)

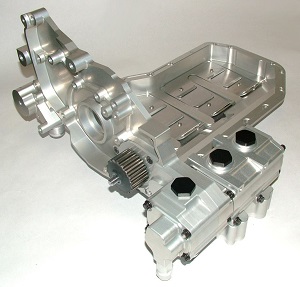

Machined from billet & not cast.

Dual-ported to aid rotor fill at high rpm and deliver a more stable oil flow sooner & for longer.

Stages dowelled for true alignment.

Bearings at front & rear of the shaft.

ARP fasteners used throughout the pump.

Common female inlet/outlet port threads.

The sump pans will also be machined from billet aluminium.

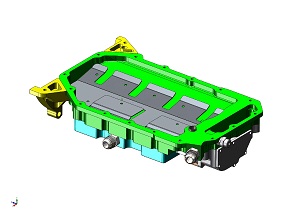

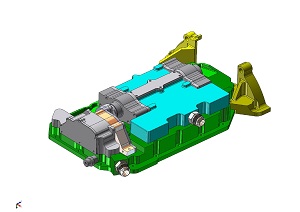

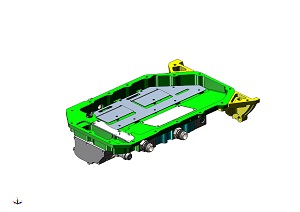

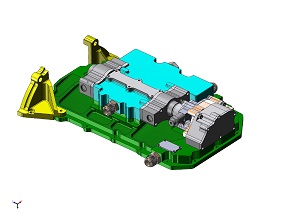

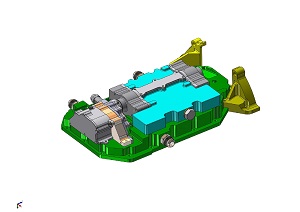

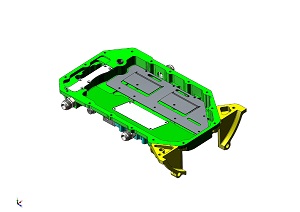

I’ve put up a picture of their latest Evo system drawing and prototype to try and give a taster of what AT Power’s ability is. The K20 would not be able to work like this image as the chain for it will not allow it to be driven to far outside of the silhouette of the skirt of the block. This means that in comparison, the pan may grow a little in depth due to housing the pump although it is still expected to end up around 1/3 shallower than the standard pan.

The technical drawings for this system are being produced at the moment and should be finished by the end of the month. Then once the design has been signed off, a fully functional prototype will be machined and built up, ready for some vigorous testing, both on the bench and on track.

I’ll be fitting one of these systems to my car but I’m also trying to see if anyone else is interested. If enough people potentially want a kit, then there may be the option of doing some sort of group buy. I already have a small list a people but could do with getting a better idea of overall numbers to see what sort of deal I can arrange. So if anyone is interested, please send me a message with some contact details so that I can keep you informed about progress. On a side note, we’ll most probably be working with ProAlloy to make us an oil tank to use with this system. However, this will be a tank with a difference and I’ll hopefully be able to provide info about this too in due course, as the kits will not come with any pipework or oil tanks.

At this point it’s probably worth mentioning that I have absolutely no financial involvement with AT Power with regards to this project. I have nothing to gain from it (financially) apart from ending up with a suitable system that’s available for me to buy!

Well I think that’s about for now, but I’ll try and keep this thread up to date with any additional info I get.

Thanks for reading.

Jamie