Hi all,

Introduced myself long time ago. Some know me from seloc. As I found lots of information here in the past decade, and I have the window banner of exiges.com on the front, I need to put my car here ![]()

After stopping with driving cars on track in 2000 I started driving motorbikes. Fast road, track and the ring. After losing a bunch of mates on and off the ring and mates stopping with trackdays I sold everything and started with cars again.

S2 135R was great but it did not catch me

I made side step to an Evo 6. Some trackdays, the ring and snow tyres in the german mountains later I sold it. Fast and fun but also getting bored.

I wanted an original Exige S1 but I did not want to make a tracktoy our of an original exige s1.

A noble but an idiot mistake as back then they where 18-20k…

So bought the Elise, like pictured below. Lots of osmose and paint chips but with an old Duratec installation that was reliable and worked but was far from optimal. Exhaust header very narrow and lots of heat next to drive shaft, intake that sucked in lots of warm air and very very noisy. Cooling was ok but not perfect.

Picked it up near London, drove it on the train and back home through France, Belgium and into Holland.

Couple of weeks later a trip to the ring.

On my way home I noticed my ears started to have a beep and the passenger had the same fun. Also noticed the lack of power due to heat soak, car peaked at 200km/h.

So it was a fun day but it needed an Exige body and the conversion needed improvement.

Short search made me rent a van and drive to, if remember correctly, to the west midlands to pick up copies of the exige clams with a motorsport roof and engine cover.

Also later bought from him a motorsport rear wing and supports and good to go!

Couple of months later it rolled out of the garage.

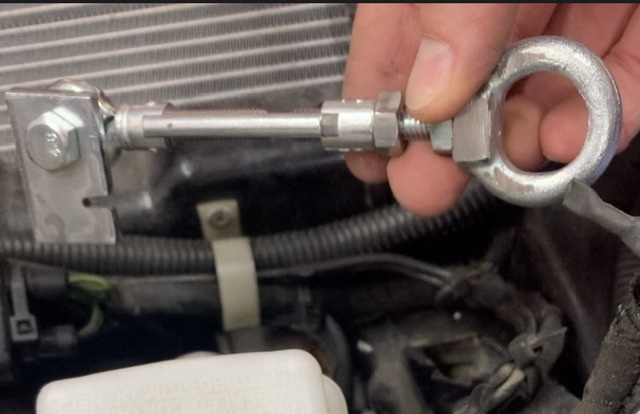

And months and months later, with an new used 2l duratec as the first one killed itself (camshaft did not get oil so got stuck) and a full over the subframe 4-2-1 with repackable exhaust, jenvey airbox on the ITB’s, lightweight flywheel and replaced the old nitrons with a fresh set of quantums shocks it was much better to drive on street and track. Had lots of small trips to the Eiffel, visited the ring without doing a lap, toke it to work a couple of times and did some trackdays. Busy times as I was only in Europe a couple of weeks a year, rest I was in the US.

Zolder (one of the many charity days)

Zolder sideways on a different day

Zandvoort

Spa

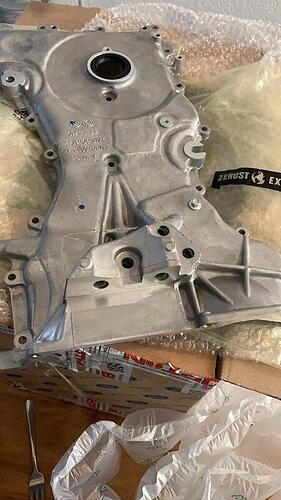

I found a brand new Duratec 2.5 i4 engine and decided that I first wanted to make the conversion technically 90% as I noticed one of the mounts broke, cooling was not 100% and the oil ran hot on Zandvoort. Not so strange as on one of the days it was close to 40 degrees Celsius. The sea was a better option!

The new Duratec engine. 500cc extra.