Whilst waiting for the chargecooler bracket/install to be resolved I wanted to finish a few bits off.

Suspension is all out of the house, so that left wiring and ECU stuff. Apologies in advance if this one is a bit long and dry, by its nature - there aren’t many photos to post here.

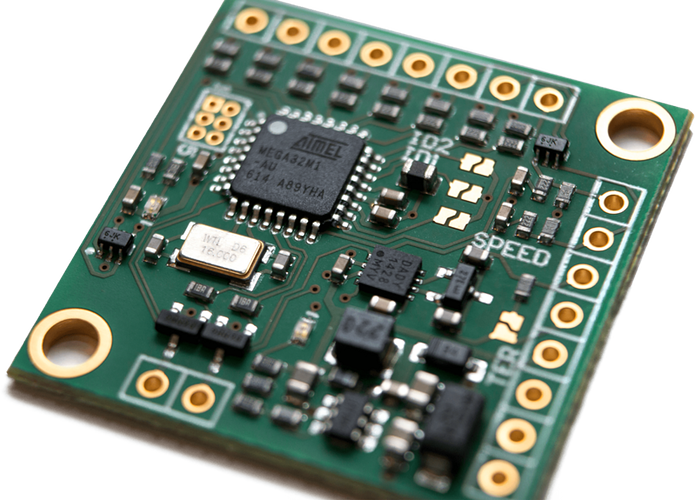

As per the theme of this thread, this part of the project would be fitting a load of parts that I took from my Exige before selling it. Specifically the small ECUMaster stack of stuff I have.

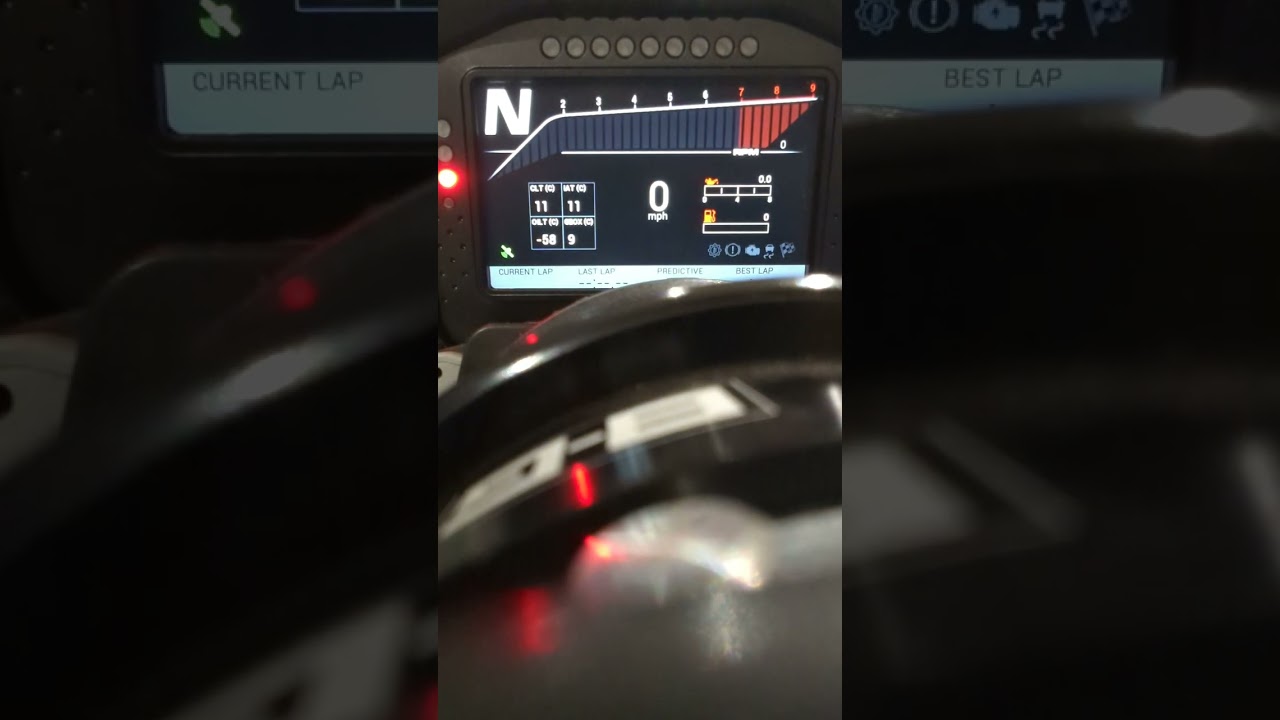

(the dash has been in since summer, but with a limited feature set because the CANbus data in the pre-2008 Lotus cars is very limited).

Adding to the dash would be the EMU Black ECU and the EDL-1 data logger. Not photographed are also:

- ECUMaster GPS2CAN (lap timing etc)

- ECUMaster CAN Switchboard (adds a shed load more I/O into the CAN network)

- ECUMASTER USB2CAN (allows management of the various equipment via the CAN network)

- TPMS 2 CAN (tyre pressure and temp monitoring real time)

For anyone who’s not worked with a CAN network in a car before, they’re really a doddle. It’s just a serial bus network with a start node and an end node (can be any equipment that has a termination resistor, usually enabled/disabled by software) which in this case is the ECU and the ADU. It has just two wires, Can H and Can L. You can splice into these to create spurs from the network and add as many CAN appliances as possible. You can also daisy chain spurs, within reason. My ADU already has a spur coming from it with the GPS2CAN unit on it, so I’ll branch out of that under the front clam where there’s plenty of space to store the TPMS module and the CAN expansion module (more on that in a future post).

My goal for this car is to make as much as this stuff plug and play as possible. I do not want to be hacking into the factory wiring unless it absolutely cannot be avoided, and I want returning to ‘stock’ to be as simple as unplugging the kit and plugging the standard ECU back in.

I’ve almost achieved that goal, but with one exception.

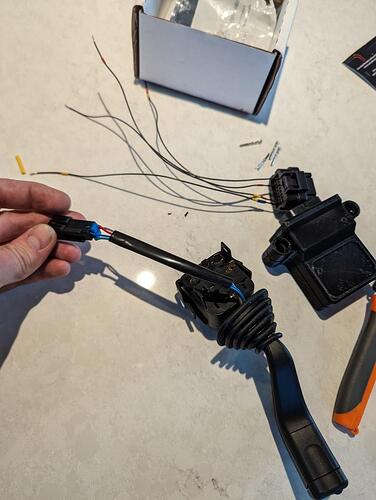

The Lotus ABS unit sends data to the standard ECU to provide wheel speed data for all four wheels. Even though the EMU Black is a PnP unit for the 2ZZ Lotus cars, it was not pinned for the 4x wheel speed sensors because it lacked the I/O capacity. The ADU dashboard that I have acts as an expansion module, and has digital inputs to take this wheelspeed data… so I’d have to splice into the wiring from the ABS unit to the ECU, and divert it into the dashboard. The Dashboard then sends the wheelspeed data over the CAN network for the ECU to use for TC activities.

I have been thinking about this for most of the summer to try and find an efficient way to avoid hacking into the wiring, I even considered making an adapter harness for the whole ECU but ran into difficulties sourcing the appropriate connectors etc, plus the costs were just spiralling.

In the end, I decided I’d need to compromise here and cut the standard wiring, but I did it in such a way that I feel it’s both robust, tidy and easily reversible.

In effect I chopped the four wires, and added a 4 pin DTM connector. This would allow me to re-join it to the factory wiring from the wheel arch if needed, without any tools or recrimping. An additional male connector was then added to the four wires leading to my ADU.

A simple and tidy splice hidden by heatshrink would have been the way any other installer would do it, but I feel this way gives me a perfect rollback.

With that done and tested, I moved onto some other ADU housekeeping. The ADU writes its logs to external USB and previously I had this wound up and stuffed into a random panel gap somewhere out of the way, but wanted a neater install. Same for the D9 serial connector for the USB2CAN module.

I’d be sacrificing (drilling and cutting) pretty much the only interior component which is common across the Elise/Exige range (and hence easy to replace if returning to stock) and ran the wiring to this, with the USB stick and D9 port sticking out, out of eye line just below the unit.

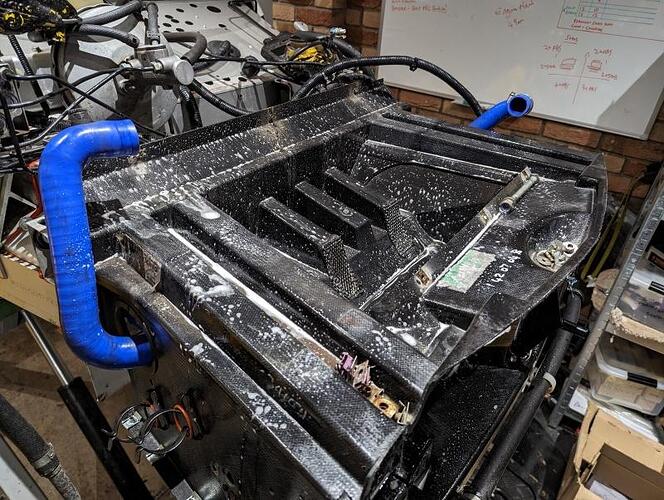

Continuing my theme of butchering the original car as little as possible, I next came up with a wiring plan which would eliminate any splices or cuts into the original engine bay wiring.

The ECU was already PnP so the bulk of it was taken car of by the stock connectors, but pins that are empty on the OE Lotus application are used by the EMU for the wideband lambda and the EDL data logger, so pins were added for those.

For various requirements I needed ready access to +5v, +12v and grounds. Obviously picking up a random earth point covers one of those things, but for the +5 and +12 I ran a trunk of wires all the way back from the ADU. As the ADU was a custom home made adapter harness, I could cut and splice into that to my hearts content. Running back through the gear lever tunnel to the rear bulkhead I had all of my analogue inputs (for various sensors), +5 and +12v. From there it split off to the various parts of the engine bay.

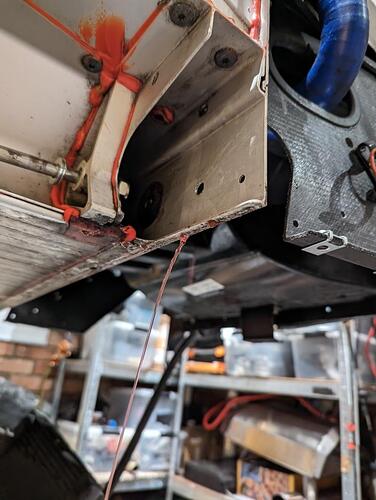

Also in this trunk were the two switch to ground outputs that the ADU provides. These are controlled by software and are connected up to a pair of relays that I’ve mounted in the battery box.

(needs tidying up, I know I know)

These relays will power the chargecooler pump, and the gearbox oil cooler pump (more on this later). Software in the ADU controls when these kick in, the CC pump will be running pretty much whenever the ignition is live and the gearbox oil cooler will be when the gearbox oil sensor reports a certain threshold.

From the battery box and relays, a small sub harness will go off into the engine bay to the two pumps.

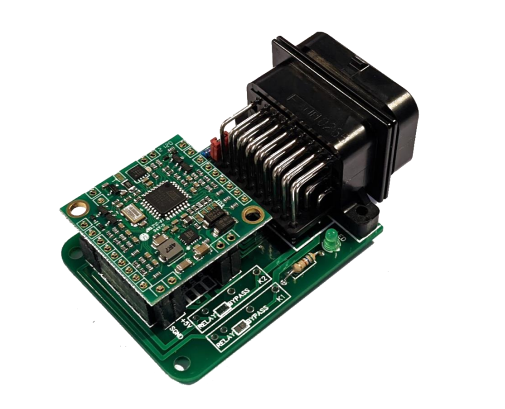

Back to the ECU, I added two pins for the wideband adapter. These add to the four narrowband pins in the OE loom via this adapter harness, made and sold by RRR Engineering:

As readers of my Exige thread will know, I was plagued by lambda sensor failures on my previous EMU install. Since ‘retiring’ the ECUMaster kit on my Exige, the fault was finally acknowledged and a wiring fix was proposed that would add a trace amount of voltage to the WBO VS wire via a 150k resistor. By all accounts, this drastically improves sensor life so I modified the adaptor harness accordingly and added a resistor in to a +5v taken from my “ADU trunk”.

Another issue I had with the EMU on my Exige has also been resolved via a software update. Most (all?) OEM’s have redundant potentiometers for their DBW sensors at both the pedal and the TB. If those readings don’t agree with each other (known as a plausibility check), the car throws a DBW fault code and (probably) goes into limp mode. Clearly a very important safety feature for DBW cars.

The EMU supports all of that, but it was missing the potentiometer correlation options within software to match the Toyota/Lotus setup. This meant that the secondary potentiometer from the TB was being ignored by the EMU for my car (despite being an active wired in input), and any other Toyota/Lotus car out there.

I’m happy to report though that I raised this as a feature request, sent logs over of my potentiometer voltages and their relationships and within 10 days ECUMaster uploaded a new firmware version for this check.

Onto the EDL logger, it has four pins with only three of them actively used (fourth added for a possible future featureset).

+5v (again taken from my ADU trunk)

Ground

Transmit (redundant, for now but pinned into the Receive pin on the ECU)

Receive (pinned into the Transmit pin on the ECU)

The RX and TX pins on the ECU were unused on the Lotus install, so this was just a case of pinning them into empty ports. These can be left in place if the car is ever returned to standard or depinned. Whatever.

I added a 2pin DTM connector to get my power and ground from the ADU trunk.

The 2-Eleven has a rotary dial for TC level in the OE wiring. This didn’t require any hardware changes at all to work with the EMU, just a quick scaling of the voltage table for it. The EMU treats the first ‘click’ of the dial as the TC-Off position, whereas Lotus used a dedicated toggle switch. I’ll be recycling that toggleswitch as my map switching button.

Aside from the physical wiring, I did a heap of software stuff to rejig the CAN stream and get the ADU displaying the wealth of data from the ECU. There wasn’t much left after that than to get the actual ECUs swapped out.

I’m very happy with the install, just aesthetically it looks loads better than how my Exige was wired in without little spindly 22awg wires reaching across between the two ECU plugs etc. I acknowledge that my approach of running a trunk from the ADU, and adding DTM connectors everywhere has added weight and complexity but I’m also very happy that by undoing a couple of plugs, swapping the lambda sensor and induction kit is all there is between standard and modified.

Time for first power up, no engine running yet because bits of my engine are still scattered all over the garage! Couple of tweaks to tidy up the config and display setting, but I had all the basics covered. Oil Temp is showing -60ish because it was unplugged at time of filming.

Page scrolling is done by the old trip reset button, ‘race mode’ is my map switching which currently just changes throttle mappings - might do more later depending on the dyno experiments. Plan to run a map close to OE power, and one which is unleashed. I have some more buttons that I’ve not got a use for yet, but I’ll come onto those in a future post if I can think of something.

As for the actual mapping, it’s provisionally booked and as I may have mentioned earlier the plan is to run two maps. One will be close to OE power output in an attempt to preserve the gearbox, the ‘race mode’ will be uncapped on whatever it makes. Not sure yet whether we’ll be using purely throttle mappings to achieve this, ignition maps or a combination of the two. We’ll see how it responds on the dyno.

Bit of work to do before then though