With dyno day fast approaching. I got the car outside and made sure that it did basic things… like forwards, backwards and stopping.

The forwards and backwards were OK, the stopping less so. I slammed on the best I could at <5mph and triggered a couple of tiny lockups. This allowed me to re-bleed the brakes and get a bit more air out, nowhere near ‘done’ yet but probably safe enough to drive onto a trailer, and maybe up and down the road a few times when bodywork is back on.

Out of curiosity I put the wishbones back on without any camber shims. On the Elise/Exige cars it’s a struggle to get more than ‘book’ camber of about 0.5 degrees at the front. Aftermarket arms/machined uprights/etc can be had, but even then my Exige maxed out at 1.5deg.

With no shims, the 2-Eleven goes full stance mode!

I lobbed some shims in just to give me a closer starting point for when it comes to geo. 2-Eleven will be aiming for similar to what I ran on the Exige, as per the book.

With that sorted, one final check over of the car (found a cam position sensor unplugged!) it was time to load onto the trailer.

Trailer did not like being woken up, with one brake jammed on for its first 4-500 metres. Luckily it sprung loose…

Strapping the car down without bodywork on was an absolute delight. I’m going to resent the bodypanels when they’re back.

I was booked onto the dyno at 4pm, over in Liverpool so meant for a lunchtime departure. Lovely day for it, pleasant drive over the M62 and no trailer gremlins after the brake freed up.

Parking on the industrial park was a concern, but luckily it was chucking out time for more places so the little carpark was deserted and I didn’t feel guilty doing this…

Back to EFI Tuning.

I stumbled across Chris a little bit by accident when I wanted the Exige mapping. I’d wanted a second opinion for a while over how the car/ECU was originally delivered to me and despite Chris not working day to day with the EMU Black nor 2ZZ cars, he fixed some idle/drivability issues that other specialists had really struggled to get the head around. Further to that, he was happy to talk me through everything he did - and even after bringing the Exige home we continued to chat about things for months, I learned a shed load from Chris - so it only seemed right that he get the pleasure of putting up with me again.

Dyno days are supposed to be exciting, but I was apprehensive about this one. I was repeating my Exige path step by step, and that ended in tears. The car had been in bits very recently, with zero road miles to shake it down… was I going to fill his workshop with pressurised coolant, fuel, oil? Was a wishbone going to fall off at 8000rpm? Who knew…

Spoiler alert, none of those things happened.

We did have a drama I hadn’t even considered though… how the hell would we get airflow through the car without blowing Chris’ head off. The big dyno fan would have demolished him over a few hours of tuning so we settled for some little ‘sidepod’ fans. It may compromise the overall airflow through the chargecooler and water radiator, but we could monitor that and adapt if needed.

All rigged up and ready to start.

The map on the car was essentially how my Exige finished off. There was a slight change to fuelling strategy this time, on the Exige I used the aftermarket fuel pressure sensor to add a modifier to the fuel table. This meant for a ‘flatter’ fuel table than you’d see on the OE application, or most other tuned 2ZZ as there’s no fuel pressure data on the stock engine.

This time, as the variable TC switch took up an extra input on the ECU I had to wire fuel pressure to my dash, and send back to the ECU via can network. For this reason I didn’t want to use it as a mission critical sensor, and instead just have it for monitoring/diagnostics. The fuel tables now will rise with manifold pressure instead.

Chris was very aware of my gearbox woes and concerns, so we had a plan to see what we could do and give some options to preserve it. Ultimately you’re playing with fire at any power level above OE, there’s no magic cut off point and it’s not unheard of for cars to smash 3rd gear even at OE power… it’s just a sliding scale of likelihood.

After some initial installation runs, tweaking the idle and refamiliarising himself with the engine and map it was time to start hunting for power. Despite having a base map from an identical spec car, Chris went through his program regardless and spent time revving up to 6k RPM without any cam switch to experiment with timing and optimising the “off-cam” power delivery, then he would reverse and tweak the cam switch before finally overlaying all of his results and finding the best crossover points.

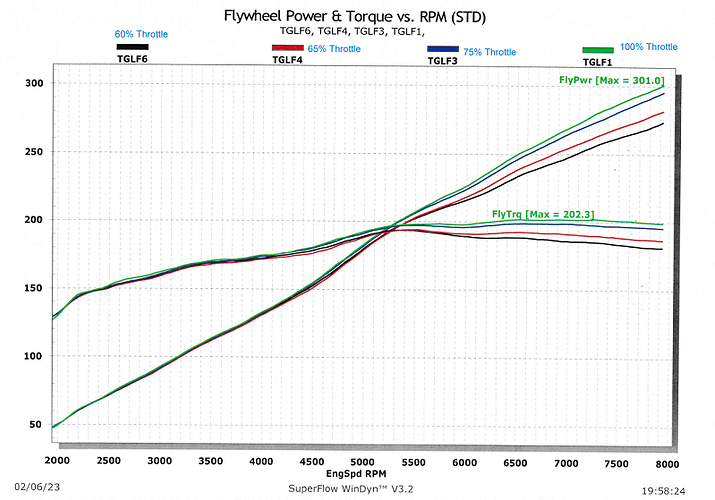

Then it was onto the power runs, with the car in my “race mode” designated map the car quickly made the exact same power as my Exige, within 1bhp and 2ftlbs. The headline figures were:

301bhp and 202ft/lbs torque, calculated flywheel figures.

On my request Chris was doing the pulls in 5th. I think technically it’s the best gear to use in this application because it’s the closest ratio to 1:1, but the dyno figures all that stuff out anyway. For me I just didn’t want him smashing 4th gear all over the place! (3rd and 4th are the inherently weak ones, 5th and 6th are not really heard of breaking).

With that done, we turned to options with the ‘road mode’ map. Following the example set by Lotus with the 2ZZ SC cars we figured the path of least resistance would be to peg the DBW back and figure out what impact it would have on boost, and power.

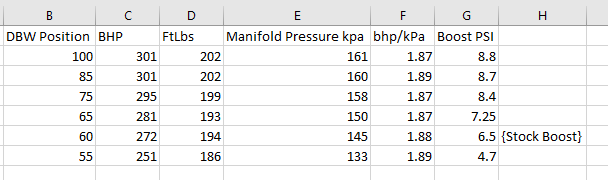

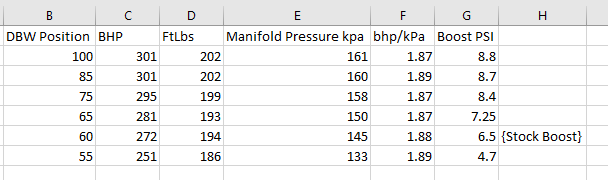

We a did a load of runs at different throttle configurations and came up with the following results

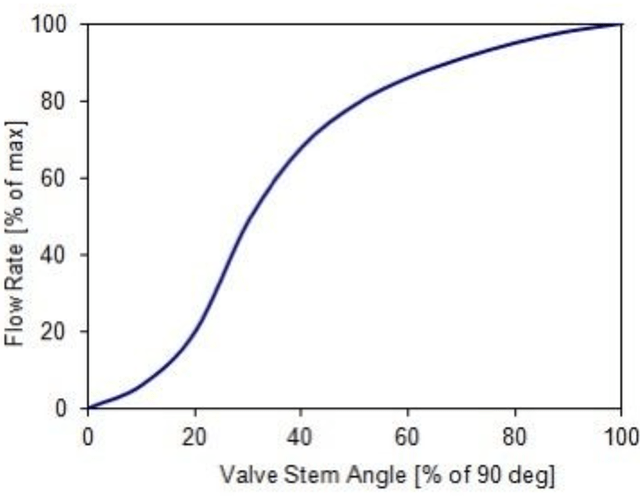

Though probably not surprising to somebody who knows what they’re talking about, I was amazed at how much throttle opening we had to trim to start having an impact. I was introduced to this chart a bit later which describes flow rate vs opening angle of a butterfly valve which correlates and makes sense once you consider that.

To get a 20% reduction in flow, you need to reduce the opening by almost 50%!

Plotted on dyno graphs:

The boost is a bit interesting (to me, anyway) in that the 272bhp and 251bhp maps can’t actually maintain their levels of boost to the redline, and the boost starts tapering off as the engine flows more and more gas.

With all things considered, we decided to go with the 272bhp map as my ‘road map’. It runs very close to OE boost levels, the SC is of course still running at the same very high RPM thanks to the 2.9" pulley but it’s reassuring to think that the other components are only under the stress of stock boost.

We spent a bit of time after this optimising the maps, to try and keep the same levels of BHP and Torque up to around 4.5k RPM, so low speed drivability and responsiveness will be the same but torque will be capped at the slightly lower level once heading into the higher RPM ranges.

Long term I’m also going to have a play with throttle limits by gear. The EMU gives me the opportunity for example to run 60% throttle in gears 1-4, then 100% throttle in 5 and 6. This could be a best of all worlds map, gives me a bit more punch to try and overcome the 2-Eleven straight line speed handicap without threatening 3rd and 4th.

The last thing we had a play with was transient enrichments. The EMU gives the option to add fuel (fairly common wall wetting technique) during quick jabs of the throttle. It also gives the option to retard timing at the same time, usually used for knock control. We played with using this to pull a few degrees whenever there was a sharp jab of throttle, this retard event would only last a fraction of a second but acts to smooth out the generation of torque. Chris tuned this by feel, it’s not a “tune by numbers” thing which my inexperience struggles to apprehend but it’s something for me to play with. Chris has defined the ‘safe’ limits for this, and the rest will be up to me tweaking it to come up with a power delivery I’m happy with. Whether it will substantially reduce shock loading on the gearbox or not? Probably not, but it can’t hurt to try it.

IATs and CLT didn’t really suffer with the smaller fans, I have logs from my Exige dyno session and they were much the same. IATs for info peaking up to 36 degrees during a pull, then falling down to 20 (seems to be the resting temp for it in these ambients) within 20seconds after a pull. The big test for chargecooling obviously comes on track where there aren’t 20 second breaks between pulls, so we’ll see what the performance is like, but I don’t expect it to be any worse than the Exige was - and that coped with everything I threw at it, pulling 1degrees of timing at the most on a very hot day.

Got the car back onto the trailer, it clearly makes too much power now as my rear right spat one of my ramps back about 20 feet! Luckily I didn’t have bodywork on… that might have been messy if I did.

Drive home was tiring, but very satisfying. Didn’t have a single ‘installation gremlin’ to deal with, no leaks, no hoses popping off, no sensors unplugged. Everything just worked.

![]()