Some good progress this weekend.

Got my replacement door switch fitted, 5 second job which once done allowed me to put the interior back in and together. No pics but you’ve seen the interior plenty of times before.

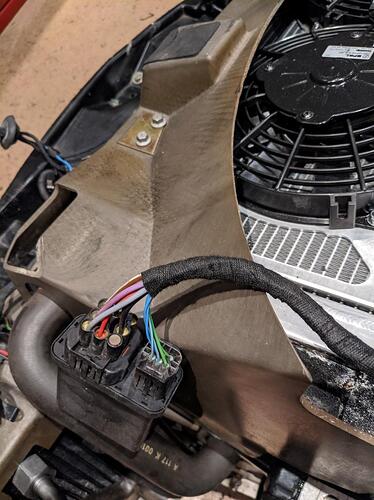

I then got a replacement plug for the charge cooler pump, so got to work rewiring that. I’m no spark, but I’m much happier with it now.

I still had problems getting a good amount of flow through the coolant circuit as referenced a few posts ago, Pro Alloy advised that it was probably an air pocket nullifying the pump but I was fairly sure I’d bled it all through as much as I could. In a final act of desperation I disconnected the feed pipe from the header tank and fed it into a cup, set the pump going and then put my mouth(!) over the top of the header tank and blew into it. My ears popped, then a second later the tone of the pump changed drastically immediately followed by a splutter and then torrent of coolant coming out into my cup. Quickly re-attached the hose to the header tank, job done. Now getting a really healthy flow around the circuit.

With the charge cooler now fundamentally working I could get to work tidying everything up, routing wiring properly, actually bolting the charge cooler to the car, etc. Lots of small jobs signifying that the end is nigh.

Of course I had to spend a bit more money, I’ve never been happy with the silicone hose joiners on the intercooler as they’re very short and I feel don’t allow any tolerance for vibration/movement. From the OEM rubber joiners I’ve seen on stock cars I think they’re about 1/2in too short so I got some new ones bought.

These have made a huge difference to how secure the boost pipes now feel, not only are the joiners longer but I think the old outgoing ones were also marginally too wide as the new ones are a much tighter fit… honestly think they’d hold boost now without any clamps!

The aesthetics of the install are growing on me, ultimately it’s a great big block of aluminium on the top of my engine so it’s never going to look amazing - but it’s about as tidy as I can get it now.

The last remaining major milestone before the car would be road worthy was to refill the brake/clutch fluid system and bleed. This is a pain in the arse at the best of times but with the system effectively empty due to a prolonged period without calipers attached, I was expecting even more of a fight.

Pressure bleeder helps a lot, and after 1l of fluid I’ve managed to get the clutch working again and I’ve got just about enough brake pedal to manoeuvre the car around the street - but no serious driving yet. I’m going to see if I can activate ABS at some point in the near future, then give it one more bleeding session. (probably after the clam goes back on)

Whilst tinkering on the brakes, I replaced the secondary part of the handbrake cable. I had the same issue on my Elise, the wishbone hangers wear through the rubber and the cable gets rusty, then starts expanding - eventually to the point it catches on the inside of your wheel rim whilst cornering. It didn’t get that far yet in the Exige, but it’s on its way.

Whilst at it I cushioned the offending wishbone hangers with some tape.

The clam can’t go on until I get this AC pipe sorted, so that’s pretty much now what I’m waiting for - which means the jobs I’m doing in the garage are getting more and more ridiculous. Highlight of the morning was re-taping some wiring loom that was looking a bit tatty:

I’ve also been p-clipping the shit out of everything. After fitting stainless hoses the factory clips for the ABS wires will no longer fit, so fitted some p-clips there to secure them:

Par for the course with Amazon Prime, I couldn’t just buy the 2 p-clips I needed so I ended up with an assortment of 100… so I’ve now been going back over any questionable wiring that either I did myself (such as during the gauge install) and securing stuff nicely with p-clips. So many cable ties now in the bin!

Finally I lobbed some new spark plugs in, old ones looked ok but I think they’re 8 years old now from what I can see in the cars history. That’s only 8000 miles (5k of which I did myself last year  ) but eh well.

) but eh well.

Next update will hopefully be AC related, and then the clam can go back on. Woop!

![]()

![]()