I’ve been maintaining a thread on Pistonheads before I knew Exiges.com even existed. Figured this might be appreciated here too so will copy/pasta it and keep it up to date going forward. Also as it’s written for a generic audience, there are some pretty “duhhhh” comments in it about the Exige ![]()

I bought a Laser Blue 2006 Lotus Elise 111R (190bhp NA Toyota 2zz) back in 2016. It was a great car, and I’d have loved for it to be a keeper but it was doomed from the day I collected it, I’d “invested” part of our new house deposit into it so it was always going to be fodder once we were ready to buy another house.

That time came in early 2018, so the car went onto a new owner after I’d had 2 great years out of it, plenty of track time and plenty of DIY servicing/fixing/improving including a suspension refurb, new radiator and front clam repair after hitting a bunny.

I’ll always view that car as unfinished business, so hopefully I can continue where I left off with my new toy.

I did think about some non-Lotus choices, stepping up to Exige budget opened up some new doors including Zenos, Caterfields and even a chubby Porsche or two crossed my consideration… but ultimately it was always going to be another S2 Lotus. The S3 (V6) Exiges are creeping into S2 Exige territory nowadays so I could have stretched to one but ultimately I want a car that I’m comfortable working on, comfortable chucking round a track and the known low running costs of the S2 platform won out for me.

I’d kept my eye on the market and one particular car was loitering around at a popular Lotus trader, priced a bit too high for me initially after just moving house but as winter approached the price slowly came into a reachable range - so I went for a look… and well, the rest is pretty obvious!

From the ad alone it ticked my boxes, Laser Blue (again!), low mileage (just under 16k) and didn’t look to be particularly hacked up or modified (that’s my job).

Whilst sat with the trader it had a couple of changes:

- Black painted front splitter, sidepods and rear spoiler

- Aftermarket “long scoop” roof

- 260bhp upgrade, offered by Lotus as a dealer upgrade but this one has been done with a Spitfire fuel pump and 550 injectors (rather than the Lotus 440cc ones) and it has a Lotus reflashed ECU.

Other details on the car are Avon ZZR tyres, it has the factory Sport and Touring option packs which I can never remember what included what but the general spec of the car is:

Electric Windows

Aircon (and it works!) *

Carpets

Probax seats with harness cutouts *

Harness Bar *

Traction Control *

Twin oil coolers *

“*” all stuff the Elise didn’t have.

The oil coolers were subject to a Lotus recall in 2014 as the crimped connectors were failing and spraying oil everywhere (nicely positioned in front of front wheels too!) but I had the paperwork to show this had been done. The other paperwork was all in order, I can’t find any record of this car on forums/clubs etc but it’s generally only done a couple hundred miles per year for most of the last decade. The only notable item in the history is a new supercharger fitted in 2012, no idea if these are a weak point or what - but the car had 9k miles at the time, so seems strange.

I test drove the car on a pretty wet day, so not ideal but it was clear (if the stats weren’t already obvious) that this was a big boy step up in performance from the Elise. Aside from the performance I noted a really slick gear change on the Exige compared to the rather vague one on my Elise, I guess this is just down to the low mileage but I’ll keep my eye out for any obvious modifications which may have contributed.

The car needed a touch of paint before we completed the transaction, the rear clam had a bit of a crack in the gelcoat typical of a car that’s had a little bumper brush in a carpark but that’s now sorted and the car is settled in the garage at home! Happy days.

I learned a fair few lessons with the Elise, spending money where it probably wasn’t needed being one big one so I hope to learn from that and get this project off to a strong start. I’ve already had the car jacked up for a poke around, mainly checking for any issues that a test drive may not have identified but also on the lookout for any sneaky modifications (none found yet, but I learned this lesson after buying a load of Whiteline goodies for my “stock” Impreza and then jacking it up to fit them, finding the car already had the entire Whiteline catalogue on it )

Inspection suggests that the car is fitted with EBC red stuff pads - they’re new to me, but so far don’t seem to be squealing or dusting too much so that’s 2/3 tests complete. If they can survive a few laps without fade then I’ll keep hold of them till they die.

Whilst the wheels were off, they got a clean and seal (freshly powdercoated, so now the ideal time to do it)

… and that’s about it so far. I have some plans already, two trackdays already booked one of which is a trip to France in May so I have some prep work to do:

- Give it a good going over with the DA and get it waxed up

- Change the toelinks to Spitfire jobbies - both a known failure point on the Elige platform with sticky tyres, but also an MOT advisory.

- Fit a baffled sump - known weakness of the 2ZZ with sticky tyres

- 4pt Harnesses, maybe

- New backbox, maybe - need to figure out if this Lotus Stage 2 one will indeed fail the trackday limits. [This was later identified as a 2bular, not Stage2. It was too loud though so gets replaced later]

Some longer term stuff I’m expecting to need doing at some point:

- Front Clam off and replace radiator (plastic end caps are known for failing)

- Use this opportunity to fit braided brake hoses and replace any rotten steelworks under the nose.

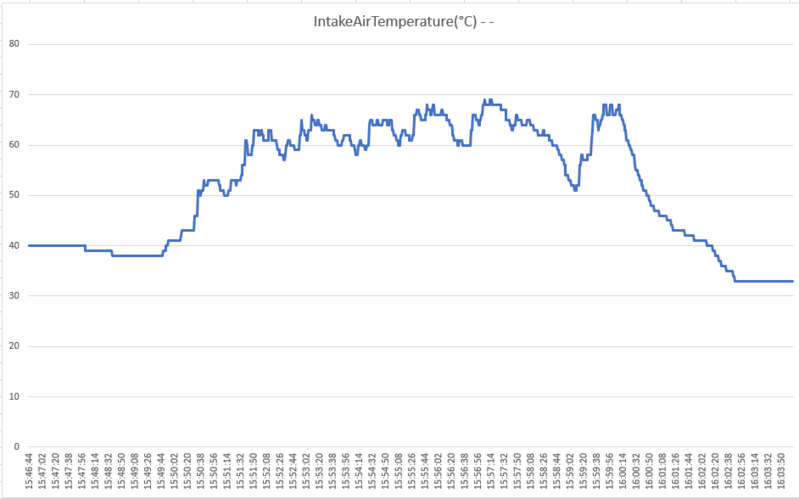

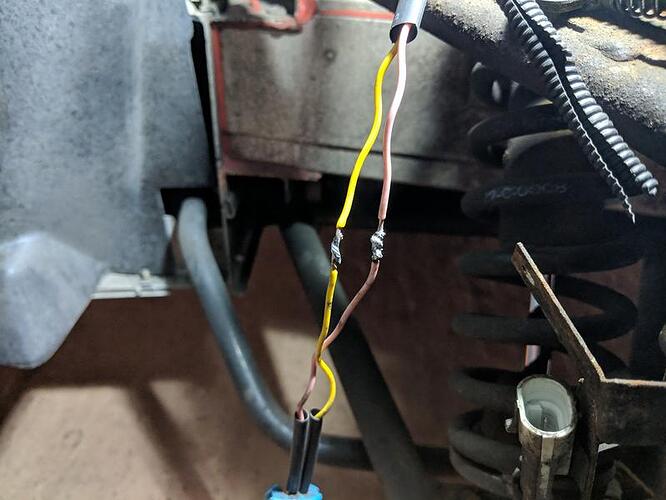

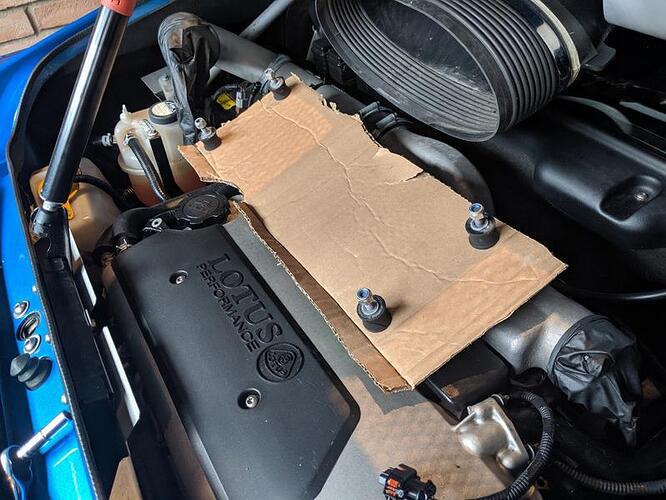

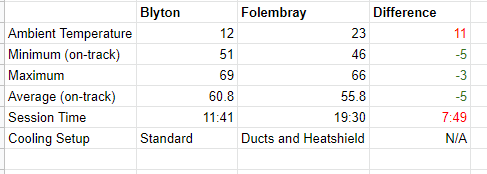

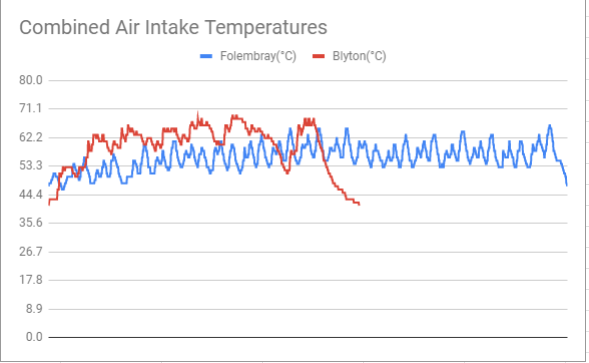

- Monitor and address airflow to the intercooler, these cars are known for bad heatsoak and poor airflow to the intercooler - but there are a few options ranging from a bit of hosing through to a fill chargecooler setup.

Ultimately the C64 gearbox fitted to this car is very close to it’s limits with a car running the 260bhp Lotus upgrade, so chasing power isn’t going to be on the agenda and I really don’t think it’ll be needed. The car feels ballistic compared to all of my previous reference points (400bhp Impreza being my previous quickest car, and I think this Exige would have it beat). The Lotus factory update also has the 440cc injectors running close to maximum, so the fact my car has 550’s gives a little headroom which may push the gearbox over the edge with the wrong supporting modifications! That said, if/when the gearbox does fail there are uprated options which may open the floodgates further… let’s see how that goes though eh.

Hopefully I can get out for some better pictures in the next few days, but on a technical note I’m going to try image hosting on instagram this time around so this thread may have a bunch of broken links… sorry about that in advance, I’ll figure it out. But for real time updates - feel free to follow @k.townend. It’ll be all car stuff, no baby photos or pictures of my breakfast - promise.