Have done the empty gearbox casing, and have also fitted a lever bar across the chassis/subframe and picked up on the sump lower sump bolts. It’s pretty straight across the mounts so no issue for moving up/down on a ramp, around workshop, etc.

Important bit is to not stress the exhaust or oil/water pipes.

Same as me then ![]()

![]()

![]()

Have done the empty gearbox casing, and have also fitted a lever bar across the chassis/subframe and picked up on the sump lower sump bolts. It’s pretty straight across the mounts so no issue for moving up/down on a ramp, around workshop, etc.

Important bit is to not stress the exhaust or oil/water pipes.

I like the idea of a bar across the sump bolts. I shall investigate (code for: I’ll do bugger all about it and complain about the same thing next time the box comes out).

Clutch out now, nothing too difficult with the removal even with the clam on.

Noticed two things, not convinced either are the root of my issue but still things that I’ll be glad to sort.

First up, needs a little backstory for anyone who has not done a 2ZZ clutch before. Some (most) clutch setups out there use a pilot bearing in the flywheel/crankshaft to support the end of the gearbox input shaft when everything is mounted up. The 2zz does not, and instead the end of the input shaft is “floating”.

This means there’s nothing in the end of the crankshaft to push a clutch alignment tool into - so most clutch kits include a plastic bush that you can seat in the end of the crankshaft. Once the clutch is fitted, the bush can no longer come out, so it’s trapped forever.

First time I did my clutch I left this bush out and aligned it by eye. After the issues I had with my first clutch being faulty, I didn’t want to take any chances second time around so I used the bush. Though I’ve not had it out of the car yet, from what I can feel with my finger I think this has melted/deformed slightly. It was a very flush fit that needed pressing in with a good few taps - but its fallen out and has been rattling about in the small gap between the crankshaft and the clutch hub. :? I’ll have to put this down to install error, maybe I put it in on the piss slightly.

Not sure what to expect after 4k miles, but the pressure plate diaphragm looks pretty worn by the bearing. The OE one I took out last year has nowhere near this much wear. The wear is also off-centre, but since the pressure plate is aligned on dowels and the release bearing is flush on the input shaft, there’s no wiggle room for mis-aligning it, so I guess it’s just manufacturing tolerances of the pressure plate.

Leading to… the throwout bearing that has been howling from cold, it feels pretty ropey to be honest after not many miles.

<LINK_TEXT text=“https://www.youtube.com/watch?v=ZKzT4o- … zeyOnTrack”>https://www.youtube.com/watch?v=ZKzT4o-exT8&ab_channel=FonzeyOnTrack</LINK_TEXT>

This may be normal and to be expected, don’t have a reference point - but a new 'yota one is going in regardless.

I’ll still be sending box off for inspection, I don’t believe this bearing or the pilot bush causing my soundtrack - but already feel like the effort has been justified so pretty happy.

I’m very intrigued by the suggestion that the lightweight flywheel can be the cause of your noise - I never knew this was a possibility and it makes some sense… I have had a very loud noise (metallic chattering/jangling) when not under load and the engine is revving north of 4500rpm, appeared as soon as the Lotus tech swapped my cams, installed the Fidanza flywheel, ACT HDSS clutch and powerflex bushes, but I had no clue what could be responsible for the appearance of the noise. It sounds like the flywheel may be the culprit?

Of all the things I’ve done, the lightweight flywheel had been one of the things I feel most deflated about - it didn’t really make the difference I thought it would? ![]()

Of all the things I’ve done, the lightweight flywheel had been one of the things I feel most deflated about - it didn’t really make the difference I thought it would?

I Feel you. I’m not disappointed in mine as such, but it didn’t set my world on fire. It’s a small incremental improvement but I wouldn’t rush to do it again.

I’m really in two minds about putting the OE one back on.

Very, very rarely use a clutch alignment tool on single plate clutch’s, think the last one was on a Lotus Carlton - an age ago! Always by eye/feel. Don’t ask about a Renault 5 turbo solution a mate used to use to great success! Leaving part of the tool in the end of the crankshaft not ideal, but probably wouldn’t be the cause of your noises.

Twin plate clutch it’s an absolute must - to the point of making/modifiing one recently for an install.

Where’s the edit button gone? As I still can’t spell!!

PS that release bearing noise is not ideal! Not sure what’s going on with the wear on the pressure plate, but does look more than I would expect. What does the friction plate look like?

Where’s the edit button gone? As I still can’t spell!!

PS that release bearing noise is not ideal! Not sure what’s going on with the wear on the pressure plate, but does look more than I would expect. What does the friction plate look like?

Cheers for the pointers, will certainly refit it by eye as I had no issue with that the first time around!

Friction plate looks fine to be honest, barely looks used. Once I got the pressure plate off the car and onto the workbench the wear didn’t look quite as bad but it’s so hard to judge without having any other reference point! It’s a bit odd how the wear is off centre though

Had a couple of opinions on the clutch now, including one from Competition Clutch themselves. Consensus is that the diaphragm wear is very much excessive, and bearing looks/sounds shagged.

CC don’t recommend reusing the clutch but can’t offer any suggestions of a root cause other than generic “fitment” issues regarding either the alignment of the release bearing or the preload on the fork. I really don’t have any scope for adjustability on either, the slave cylinder dictates the bearing preload and it’s not adjustable - unless anyone can think of something I’ve not thought of?

I’m leaning towards the bearing being naff from the get-go. It’s always howled from cold, maybe that was a clue.

In any case, that leaves me needing another clutch. The CC clutch really did have some fantastic road manners, based on its actual performance I couldn’t rate it high enough but I don’t think I have it in me to buy another one. Including the original warranty replaced one, this would be my third clutch in 12 months and at some point enough is enough! All of the go-to names have their share of horror stories with regards to road manners, chatter, etc - so it’s feeling like a roll of the dice whichever way I go.

Gearbox has been dropped off with the specialist for an inspection, so hopefully will have some analysis on that soon.

Wow. Thats a strong clutch / miles ratio there Fonzey

Surely the 2zz / c64 combo isnt that harsh on the clutch?

The actual friction materials look brand new, so it’s not a high wear rate through normal circumstances.

I suspect the throwout bearing was duff from the off, and it’s been wearing away at the diaphragm.

Understood.

Frustrating that!

I’ve had my initial inspection report from my gearbox this week, which has some mixed results. On one hand I’m glad issues have been found, as it vindicates the decision to drop the box. On the other hand, I’m obviously disappointed that the previous build wasn’t up to scratch.

The initial finding was that the inside of the box was covered in/full of loose bits of sealant from where the casing was stuck back together. You can see massive snakes of the stuff on the inside of the flange, and tiny bits floating around everywhere including inside the roller bearings. The builder doesn’t think these caused a problem as such, but it’s definitely not a good thing and is not a sign of good workmanship.

Next he found the circlip for 6th gear wasn’t seated right in the groove. It was still in place, but who knows for how long.

The next issue was an area for confusion, the builder has worked with hundreds of Toyota C60 series boxes over the years but not many running aftermarket final drives. He was concerned that the meshing between the crown wheel and pinion was not letting him remove the output shaft from the casing as he normally would. Luckily Kaaz responded immediately to a support call, and confirmed that this is very normal due to the added tooth count and you have to sort of juggle the diff and the output shaft into the casing as one “premeshed” unit rather than sliding them in independently as you can with original components. So no issue really, but worth writing down in case anybody else runs into the same confusion in future.

Finally with the FD confusion cleared up, he checked the differential preload and found there to be absolutely nothing. I wasn’t invoiced for shims when the box was originally built, which means they either got lucky and the new diff matched the preload of the old… or they didn’t even bother checking and just lobbed it in.

Of the issues found, the lack of differential preload is the most likely cause for the sound effects I complained about. The good news is that the box isn’t full of glitter, and there’s no sign of abnormal wear.

I asked him to inspect 3rd synchro too as I got the odd crunch on a very cold box. He says it looks pretty new, but since it’s out - we might as well swap it. As usual one thing leads to another and I ended up ordering a few more bits too, so gearbox build #2 is proving rather expensive so far!

Some pictures from the builder, bit blurry but you get the idea.

Small gearbox update, went through to Toyota York to pick some synchro bits up. Preventative maintenance, my current 3rd synchro doesn’t have any visible wear despite crunching when cold but “while it’s out” etc etc.

Bit of Toyota C60/C64 trivia - around 2003-04 they changed the design of the 3rd gear synchro, it’s made out of some sort of composite material vs the brass of all the other synchros. Lotus only started using this setup from 2004 so all Lotus cars should have the new version of the synchro, but it can mean you can get caught out if buying a second hand box to swap in if you wanted to transplant your 3rd/4th gears etc. As my builder primarily deals with MR2s running older conversions, he is used to seeing the older brass version.

As much as redoing the gearbox has really annoyed me, at least I could be satisfied that a lot of the other work I did last winter has lasted the year and doesn’t need revisiting. Oh wait, that’s not true.

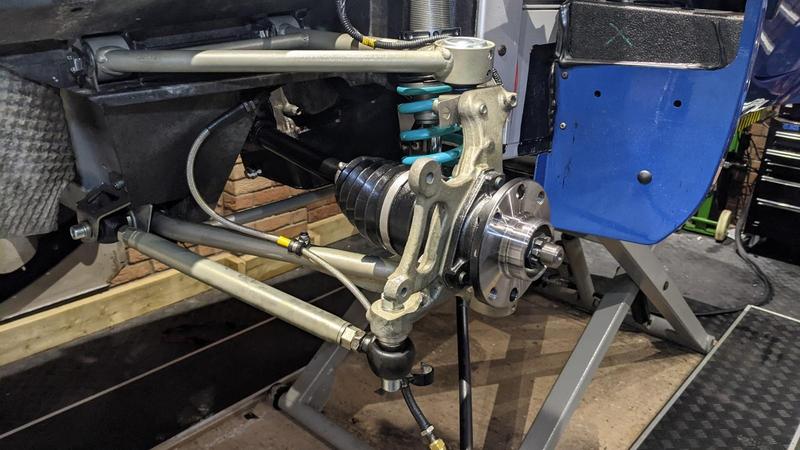

To get the gearbox off I have to remove a bit of the suspension, which allowed me to inspect the zinc plating on my wishbones. As a reminder I had these done last winter, and topcoated with POR15 clear. I absolutely loved the aesthetic of them and IMO looks about a thousand times better than painted or powdercoated wishbones.

I knew they were dirty, but I hoped that a quick degrease and rinse off would have them back to their original finish. Unfortunately that was not the case:

(the black gunk on the non-zinc plated bits did clean off just fine, such as the tops of the balljoints)

It looked like baked on dirt/brake dust at first but it seemed to be under the top coat. I tried all sorts of degreasers, fallout removers and nothing would touch it. Eventually I got a (fairly soft) brush attachment onto a drill and it just scrubbed the finish off in flakes. Absolutely gutted.

I don’t know enough about the zinc plating, passivation process to suggest what it could be. Maybe the finish was fine, just not suitable for my application or maybe some product I’ve used has caused it, brake dust, something like that. Either way, it’s not fit for purpose.

With most of the rear suspension off the car, I decided to suck it up and get the rest off, mask up and paint over with POR15.

I was pretty annoyed throughout this whole process, but I’m fairly happy with the end result.

I wire brushed the remaining visible plating off first

Then went through the POR15 process of degreasing, rinsing, drying, metal prep, rinsing, drying followed by painting. Applied by brush in my fairly convenient carcass of a kitchen that I currently have.

Some other bits got done too, like engine mounts, suspension mounts and anything I could find showing a bit of rust.

We’ll have to see how this lasts, but I’m hoping longer than just one year… One thing I did note is that between phases of the POR15 process the items spend a lot of time just air drying and I didn’t get a spec of rust appear on any of the zinc plated items. I’m wondering if it’s just the gold passivation that failed and the underlying zinc is still doing its job. Maybe wishful thinking, but perhaps they’re at least now double protected.

I haven’t even removed the fronts from the car, I don’t have the motivation to touch those yet. Maybe later.

Dissapointing after the investment in both the gearbox and the coating that you have had to revist.

I do like your new spraybooth though.

Yes very annoying, I love fiddling with my car but hate doing the same thing twice.

In the name of progress I swore never to refit the suspension tab washers ever again, they really are awful. Nordlocks going on with some fresh nylocs.

Some positive steps taken this week, started bolted bits back onto the car which is always a nice feeling. Just small bits like engine mount supports and wishbone mounts, but progress all the same.

Also had an update from the gearbox builder, new synchros are in and everything cleaned up ready for reassembly.

The differential needed two of the thicker shims to get it preloaded, so it was miles out but he’s happy with it now and it’s bang in the middle of tolerance. Various bearings swapped which should have been changed last time, but weren’t - so fingers crossed this will be the gearbox build to see me out!

Waiting for clutch next, SeriouslyDave is sourcing me one from down under so it may take a while yet. I’ve got an opportunity to do some exploratory work for the gearbox cooler I planned to add this winter, so I’ll crack on with that in the next week or so. Hoping I can find a home for the laminova core and get it spliced into a coolant hose somewhere and mounted, run the electrics and mount/mock up the pump location because without a gearbox in the car, the engine bay is lovely and accessible from below.

I collected the gearbox this week, and got the final assessment. The excess sealant inside the casing (and inside of the tapered roller bearings which have since been replaced) I’ve mentioned already, along with the complete lack of differential preload. The final issue explained to me was one with this circlip. This circlip is the final component on the output shaft (it could also be input shaft, I forgot… so consider it interchangeable for the remainder of this post) which essentially holds sixth gear in place.

Paul, my new favourite gearbox builder explained to me that it’s a common issue for this circlip groove to appear “not wide enough” when the output shaft has been incorrectly assembled. If you don’t press the various gears/bearings/etc on to it properly, it means the shaft is allowed to sink too far into the casing which means not enough of this circlip groove is visible at the top. He has methods using heat/cooling etc to expand/shrink the various parts to make this process work, but he says any attempt to press on with brute force will usually end up with a fraction of a millimetre of misalignment. From looking at this circlip, the previous builders’ decided to grind it down to make it fit, rather than align everything on the shaft properly. ![]()

Ultimately this would have meant nothing on the shaft was aligned right, and in theory would have been a slight mismatch to the meshing of the gears. Whether it contributed to my noise or not, who knows - but it certainly wasn’t right.

I’m actually amazed this gearbox lasted the year based on what has been found. Very annoyed, but also relieved that it’s now sorted and I’m confident it has been built to a proper spec.

Obviously we won’t know if the box is any quieter until it’s back in the car. The lead theory is still the lack of differential preload, so hopefully resolving that has sorted it. Paul is still a little nervous that the noise might be an unavoidable result of the final drive that I’m using, as the tolerances between the crown and pinion are much much tighter than an OE setup. Although I’ll be disappointed if it still makes a noise when it’s back in, I can live with the fact its now had a thorough inspection and I’d have a legitimate reason for the soundtrack. It’ll just have to go into the “because racecar” bucket of explanations for stuff.

Opportunity for a cheeky pic of the new daily doing its part to keep an old relic of a bygone era going.

Sounds like it was fortunate you opened it up when you did!