I’ve had an offer to loan some steering arms that are currently sat in a box for a project that’s a little stalled. I may look at them after Anglesey so I can experiment at a circuit a little closer to home.

I had my AC guy back round last thursday. As a reminder, quick summary of my AC journey is as follows:

- AC worked fine

- I destroyed a few parts of it whilst fitting the chargecooler

- Condenser and a couple of pipes replaced, one pipe was custom made to give a bit more room around the CC hoses

- AC worked fine at the start of last year

Towards the end of summer, I noticed some residue on top of my OSF archliner and suspected it was from the new custom AC pipe. I wanted a fully flexi pipe but Lotus had a pressure relief valve fitted so we had to splice in a bit of solid and a bit of flexi together to accommodate it. The AC still worked absolutely fine but I stopped using it until I could get the leak verified.

Fast forward to last week, and I finally verified the leak. AC was still working a treat, but after a few mins of running at max pressure we saw bubbles of residue coming from one of the crimp connections on the custom pipe. Since we made the pipe, I learned that Lotus no longer supply this length of pipe with the PRV as it was deemed redundant, if we knew this previously we could have made it 100% flexi and had no issues, so that was the plan going forward… BUT I have very little faith we can unscrew it from the condenser whilst the clam is on. With the clam on, we can’t clamp the condenser side of the union.

Rather than risking my condenser, we recrimped the pipe without removing it. It seemed to survive the follow up pressure test, and we’ll come back to it the next time my clam is off to replace the pipe properly.

A couple of days later I was headed to Wales via and overnight stay in Cheshire to meet some friends and explore some of the North Wales roads. Not an area I’ve driven before, but so glad I’ve got to experience it.

Some belting roads, good company and no real traffic/cyclist issues all day. Long day though, was in and out of the car for 12 hours so I was pretty broken when I got home but luckily… the car wasn’t!

I did have a couple of snagging issues to address on the car though after so many miles, but should be easily sorted this week before I head back to Wales for an Anglesey trackday:

- Wheel balance is out, vibrating all over the place at

- Engine needs repositioning a bit… not as drastic as it sounds, but the rear engine mount allows some adjustment. Currently the crankcase breather is interfering with the bottom of my chargecooler header tank causing rattles at certain RPM. I can lower the engine a bit, but it’s a tightrope as I only have a few mm clearance between the cat and the rear diffuser.

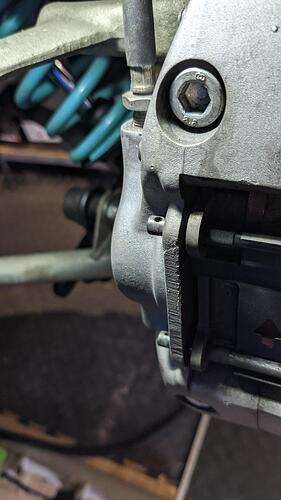

- On the way home when the brakes all cooled down a bit on the motorway I was getting nasty pad chatter up front. Not THAT unusual for these cars but it was particularly bad. Upon inspection I found that only good-will was really keeping my pads in on the drivers side…

Worryingly it seems like both pins have wobbled out, maybe as a result of the poor wheel balance vibrations, maybe the Welsh cattlegrids that we flew over at “speed” but I checked a photo from the ‘AC’ work a few days previous, and they were definitely there then!

Anglesey next weekend, can’t wait

Oh, and AC worked all weekend too. Compressor is rattling a bit though when in use.