Trackday report, woo! Sorry if it’s a bit dry, just want to note down my observations for my benefit later.

I attended Blyton Park with Javelin over the bank holiday weekend to shake the car down, and start to get up to speed before the ‘big’ trackdays of the year.

The day before I gave the brakes one last bleed and finally got that glob of air that has been plaguing me! Car felt great on the test drive, but I did notice something worrying… every time I stomped on the brakes to test, my oil pressure gauge dropped to 0bar. I went to bed that night trying to convince myself it was an instrumentation error and nothing more, oil levels were fine and nowt’ was leaking, and the OEM oil idiot light didn’t light up.

On the drive over to Blyton my indicated oil pressure started fluctuating wildly, I pulled over and checked levels/leaks - still nothing - so I tiptoed to Blyton and hoped for the best. By the time I got there, the gauge was completely knackered and just kept flashing “FL”. Either it meant “Fucking Low!” or it was some kind of error code, either way the car was still running and had a sump full of oil so I decided to ignore it and hope for the best.

Spoiler alert, the sender wires had gotten pinched between my sump and one of the undertray naca ducts:

Onto the track, the car immediately felt fine. No fireworks, no questionable handling traits, no weird noises or sensations - it just felt ‘safe’. Pleasant surprise, but I was way off the pace just trying to be on hyper alert to anything falling off.

I gradually built up speed through the day, but still a fair lick away from my best at Blyton. I can’t blame the car for that, just a rusty driver combined with a very crowded track I think.

I’ve spent the last couple of days reflecting, trying to evaluate the car and the various changes. My summary is as follows:

Anti Roll Bar/Suspension Geo/Bushes(?): The showed no particular bias towards under or oversteer, it just works. Perhaps this is a result of me being a little bit slower on entry than I’m used to at Blyton - not pushing hard enough, but it felt like a great base to push forward. I was concerned the ARB would introduce some front end push, but no evidence of it. I had it set to the middle of three settings which in theory should be a bit stiffer than OEM. I’m not sure whether it was the ARB, bushes or both but the car felt a lot more direct when ‘tipping it in’ at higher speeds, makes it feel much more assertive - good change, 8/10. Only thing stopping 10/10 is that I felt I didn’t push it hard enough for proper appraisal.

Gearbox - Ratios: The shorter ratios granted by the final drive change was probably the biggest thing I needed to adapt to, it’s definitely a positive change - but it caught me out in a couple of places. Previously I could lean on third gear powering through Lancaster (long sweeping left) because the power delivery was dull through the tighter part of the corner, and only got into the high torque band once the track opened out a bit. Now the car is much more lairy through the earlier part of the corner where you’re waiting for things to settle down a bit. In other areas I was hitting the limiter (4th at the end of the back straight, 3rd coming up to the first corner) so I need to be short shifting into 5th/4th and carrying more speed. This definitely makes the car feel (much) quicker, easily worth many horsepowers is my not-scientific appraisal. 9/10, maybe a bit compromised at Blyton due to not having very long straights, but expect it to be a solid 10 at Croft.

Gearbox - Differential: I was a bit scared of the diff for much of the day because I didn’t know exactly what the car would do. When pressing on later though, I just couldn’t upset the rear no matter what I tried. The car has bags of grip, where it used to spin the inside rear I was expecting the car to slide with an LSD, but it doesn’t - it just pings me out of the corner and I’m gone. On a quieter track I’ll play with it a bit more and see what else it has to offer. 10/10 - no notable downsides (yet).

Brakes - Carbotech XP8 pads: It seems like a lifetime ago that I fitted these, but this was my first track outing on them. Easily the best braking setup I’ve had in any of my cars, so much more stopping power than the RS42s (should be a given really), but I’m reluctant to compare them against the RS14’s I had purely because I ran those with a cracked disc - so not a fair test. My stopping distances were so short, in the morning I actually had to get back on the gas a couple of times before turning in  Seriously good, they don’t seem to have worn excessively but they did give off lots of dust (which hosed straight off) and they do clatter around in the calipers a bit now they’ve had a few heat cycles in them. 8/10, only the noise stops 10/10.

Seriously good, they don’t seem to have worn excessively but they did give off lots of dust (which hosed straight off) and they do clatter around in the calipers a bit now they’ve had a few heat cycles in them. 8/10, only the noise stops 10/10.

Airbox/Induction Kit: The only negative from the day really, it was really really noisy. Not enough to trip sound meters, I think it’s just limited to the inside of the car but the supercharger shriek is borderline painful now, even with a helmet on. 3/10.

BUT…

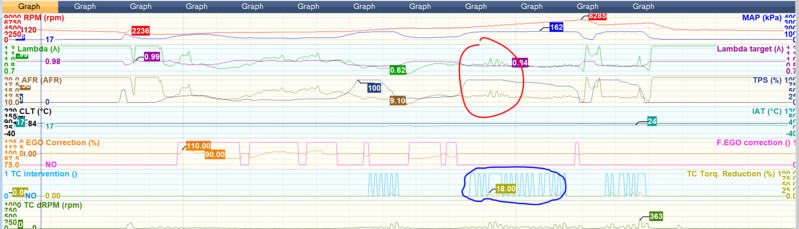

From checking logs from the ECU, my car is making a bit more boost since my winter tinkerings… I’m not exactly sure why, but I can only think it’s the airbox being less restrictive. Car was peaking at 9.6PSI compared to the 8PSI it was making last year…(averaged across all trackdays, ambient temps have no appreciable impact) I only noticed this as my ECU was no longer correcting fuel via wideband (I found the wideband correction to be capped at 160kpa for some reason, so quick fix to up it to 180). This suggests to me that the filter is definitely a positive change as far as the performance of the engine is concerned… so perhaps the 3/10 is a little harsh!

The car suffered a couple of casualties:

-

My internal gopro mount, it’s a bit broken. I thought it was just too slack when I initially reviewed my footage (mostly of the back of my helmet) but it seems like it’s taken a knock and needs replacing. No big deal, but does mean all of the video I’ve checked so far is trash

-

I lost both front centre caps, one was later returned to me - but the other one is long gone. Pretty stupid, every set of wheels I’ve had on every car I’ve ever tracked has had this problem, so normally jam the centre caps in with tape - totally forgot with these wheels.

So pretty successful day really, certainly a good base to build on this year. I also got to meet my cars doppleganger…

Pretty much the exact same spec as me in terms of chargecooler, gearbox upgrades, suspension/ARB etc… he’s just running a smaller pulley so making a bit more power. Didn’t get to share the track with him, but it certainly looked to be flying when I saw it from the sidelines.

Anglesey next (May BH Weekend), will get the gauge fixed and other than that - just a spanner check and hopefully some road miles to enjoy the car a bit between now and then.

![]()