I was hoping to have everything back to where I was by the end of this weekend but Royal Mail let me down by not showing up on Friday, which means no pressure plate bolts. I’m 99.5% sure I could have just reused the old ones without drama but I want to leave absolutely nothing to chance this time!

On that note, it did let me have some time to do a little housekeeping on the gearbox.

I mentioned on a previous post that one of my slave cylinder bolts had a bit of a chewed thread. It’s not too surprising, when you refit the slave you’re pushing against the pressure of the spring and brake fluid pressure to compress the piston all whilst lining it up with bolt holes that you can’t really see, and also trying to fit the SC support bracket to the same bolts. I’m wondering if the damage was done years ago when the SC was swapped, might explain how the bracket ended up snapping if it was never bolted in right in the first place.

Anyway… I stole an idea from some other thread I did and put some studs in instead, makes the whole job a lot easier. I did this whilst the box was in the car previously and I was happy with it, but now the box was out I thought it was a good opportunity to see just how bad the threads are:

Hard to see on the photo but the first few threads are missing completely, but the ones further in are sound and will easily take the load… but as I said before, I’m leaving nothing to chance - so I drilled it out and tapped it to M10.

Followed by an M8 helicoil and fresh stud.

Looks exactly the same as it did before, but I’m much happier with the threads now.

I’ve done what I can with the clutch, which is getting it lined up with the pressure plate to within 0.2mm (which is well within the tolerance range for my eBay verniers!). Again I was confident clutch alignment was fine on the first install because the box went back on so easily, but this is bang on.

Flywheel also scrubbed up fine, the burn marks came off with a bit of brake cleaner and scotchbrite so happy to reuse it on that basis. ARP bolts cleaned up, refitted and torqued back up to spec.

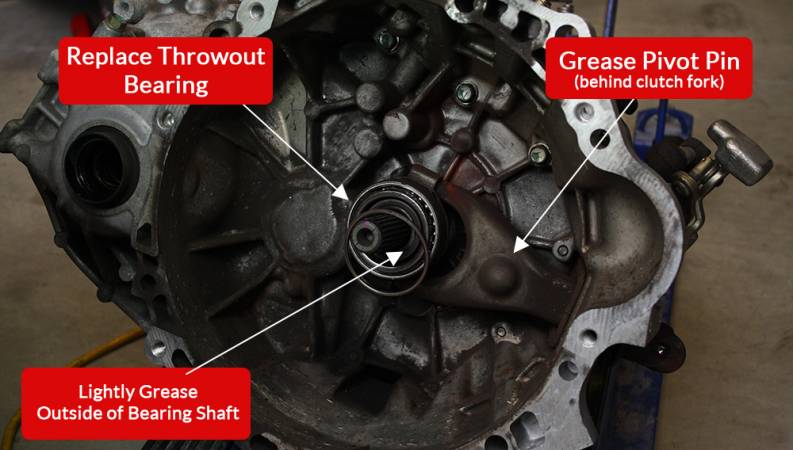

As for the release bearing, this was a bit of a dilemma. One of my early theories on the disengagement issue was the fact I’d used a Toyota OE bearing (under advise that it was likely of higher quality), I’ve since measured and compared it with the two CC bearings I now had and they’re dimensionally identical, but despite this I’m not sure if I want to ‘risk’ putting the Toyota one back in, so just to rule it out completely I’ve gone with a CC bearing instead. If it start chattering away in a few hundred miles I’ll be annoyed, but hey ho…!

Splines cleaned, regreased and ready to go. Gearbox is sat on the motorbike jack ready for install and hopefully that will be tomorrow, then I can spend a few nights rebuilding the car to be back to where I was a week ago.

Really, really hope it works this time!