I did have a brief poke around yours when i worked on it, i think they were mostly fine, certainly nothing to worry about.

I also do my own version of them now, currently un-released to the public but they are out there on a couple of cars now ![]()

I did have a brief poke around yours when i worked on it, i think they were mostly fine, certainly nothing to worry about.

I also do my own version of them now, currently un-released to the public but they are out there on a couple of cars now ![]()

Worth knowing ( on both parts! ) thanks!

More good progress. looks very good indeed👍

I may have hit a snag, not in total panic mode quite yet - but starting to prepare myself for getting the gearbox out again…

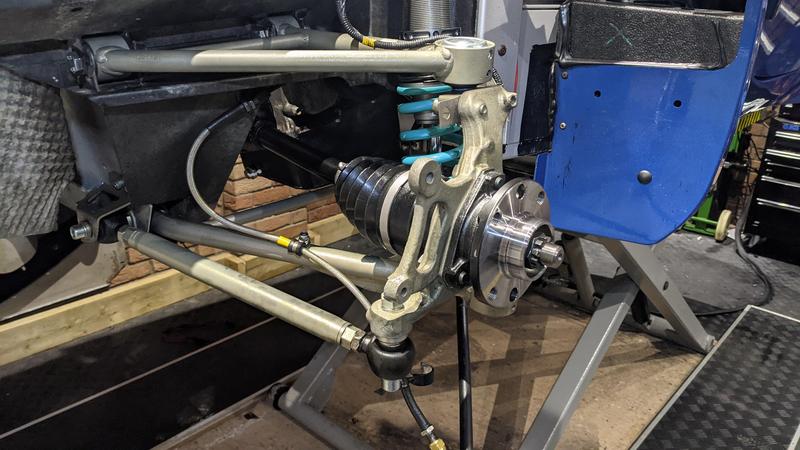

I got the rear suspension fitted up over the last couple of days, very satisfying and love the overall look.

With support for the driveshafts, I could now finally start the car. Bit of a nervous moment, I’ve had my grubby hands on a lot of important stuff but it fired right away and purred away nicely. Result ![]()

Things soured a bit when I tried to use the gearbox. It appears my clutch is constantly engaged, with the pedal fully to the floor I can shift into the forward gears but the hubs immediately get drive. Getting into reverse is a no-no as it just grinds. Bugger…

I’ve inspected the clutch fork as the pedal is depressed and it seems to be getting a healthy range of motion, but with no reference point as to what is the “full” range, I can’t really say.

Plan is to get the front uprights all assembled and get the brakes and clutch system bled. Maybe I introduced some air into the clutch circuit when removing the calipers (not sure how, but fingers crossed it is that). Aside from that, I’m open to suggestions about what I could have messed up inside the clutch assembly.

Release bearing had free movement on the shaft

Pressure plate bolts all done up in a star pattern to spec

Clutch must have been aligned well enough because the gearbox slotted straight in

Not sure what else I could have messed up in there?!

I assume the friction plate could only go on one way? IE , not sided?

I assume the friction plate could only go on one way? IE , not sided?

I’m not sure if it’s possible to go the wrong way in, but i’m 90% sure it’s in the right way… (and I did check with somebody else to be sure as the competition clutch had no labelling!).

As the days go by without a solution the 90% will start slipping I’m sure…

Every clutch I have changed let me put it in both ways. Only a sticker on a face saved me…

That looks right to me.

Next logical point is the fluid. Did you pre oil fill the master cylinder?

I’ve not touched the MC at all, when the Slave was removed from the box it remained plumbed in at all times.

There’s a chance the clutch circuit has always had a bit of air in it, and the stock softer pressure plate was maybe compliant enough to work regardless, so I will be bleeding the system fully later today to rule it out.

Another potential pitfall that’s just been brought to my attention is that I did not use the Competition Clutch supplied release bearing, I went out of my way and paid a not-insignificant price for a new Toyota one under advice which I’m sure was well intended… I guess there’s a chance that the CC one was slightly thicker, meaning it would pressure the plate earlier in the “throw”.

If that is the case, there’s a potential workaround that doesn’t involve dropping the box. A number of Toyota/Lotus parts places sell extended pushrods for the slave cylinder to solve this exact issue. Apparently it’s not unheard of for aftermarket clutches to cause different disengagement points, so this is a bit of a hamfisted way of fixing it: https://www.monkeywrenchracing.com/product/speed-source-clutch-push-rod-toyota-1zz-2zz-all/

Didn’t realise the two bearings were different thicknesses! Hopefully its a red herring and its not the case, it seems unlikely, but you never know

When you mentioned the MWR shaft I did have a look for local supplier, but couldn’t find one - is it their product only?

I’m still hoping a bleed will give you what you need and you can sit back laughing by tonight

The differing psuh rod lengths does seem to have some weight to the arguement about the clutch not disengaging

I’m not sure if the CC bearing is/was a different thickness to the Toyota one. I had both in my hands at some point, but never thought to measure. I think if they were different I’d have noticed… maybe.

I only have one photo, and annoyingly it’s top-down…

I did find one UK retailer with the pushrod, but it’s out of stock. I’ll give them a shout this afternoon: http://www.se7enmotorsports.co.uk/store/p112/Extended_Clutch_Push_Rod_1ZZ(140)_&_2ZZ(190).html

Actually another one here, in stock… but no idea what car it’s for ![]()

clutch extended push rod, mr2 gt4 glanza

Price: GBP 12.00

A few MR2 people are telling me that they almost always have to mess around adjusting their master cylinder throw when they change clutches. No idea if ours is adjustable up front, but again the longer slave rod would prove it one way or another.

Also lotuslee has told me not to panic and not do anything rash until the car has been dropped onto the floor on all four wheels. The viscosity of the oil and no load on the transmission can lead to weird engagement things…

Also @lotuslee has told me not to panic and not do anything rash until the car has been dropped onto the floor on all four wheels. The viscosity of the oil and no load on the transmission can lead to weird engagement things…

Open your garage door first before turning the engine over with drive engaged, just in case. Maybe move the focus too.

Not saying he’s wrong but no one wants to ring the insurance company reporting you’ve driven one car into your other one…

![]() Good idea.

Good idea.

He does have a point though. I had the same problem with a focus way back when on my first clutch change, I had real problems with it but it was on my dads drive and he needed me to move the car when he got home so told me to push it out the way. Putting it on the floor it just worked… I put that down to my incompetence rather than an actual solution

I got the brakes/clutch bled this afternoon and it hasn’t fixed anything unfortunately. I also tried a test where I fully locked the rear wheels (handbrake + foot brake was enough) and as soon as I try to shift into first gear, even with clutch fully depressed the car stalls. With the brakes off, it shifts into gear fine but sends drive straight to the hubs.

I’m fairly sure I’ve got an issue inside the clutch, either the friction plate is jammed stuck and isn’t sliding up and down the shaft, or the fork/bearing is not putting enough force on the pressure plate. I think to rule out the latter I’ll try one of these slave cylinder extended rods - it’s cheap and by all accounts easy to drop in, so I might as well rule it out.

Aside from that, I guess the box is coming back out. ![]()