I’ve got a bit of progress done on the car over Christmas, just 30mins here and there.

I got the car up on all fours and took the old Bilsteins off. They’re still in really good nick, so I’ll box them up for now and decide what to do with them. Some new spring seats and a dusting with some yellow paint will get them looking mint and at only 20k miles they should have plenty of legs left in them. Maybe a good upgrade for an Elise owner out there somewhere.

For contrast here is how my Elise looked after 40k odd miles…

On my Elise thread (around here: Lotus Elise 111R - Page 8 - Readers' Cars - PistonHeads UK) I went to a lot of effort removing them all, stripping and re-painting with brand new bushes, balljoints, hubs and various other goodies.

I’m not quite ready for that yet on the Exige, the bushes and balljoints all feel good (apart from the track rod ends, nicked boot means they’re up for the chop) and so doing a full refurb would be a bit of a waste at this point. Instead, I’ve soaked the worst bits in Bilt Hamber Deox and wiped the lot down with XCP rust prevention to buy me another summer or two before the big job is needed.

Eventually I had to stop looking at the Nitrons, so went ahead and bolted them up.

Everything fits without drama, as expected. I’ve wiped the threads and coils down with XCP to hopefully keep them nice. In addition to the shocks I threw some new TRE’s on the front and replaced all of the ABS shims (camber shims that are used to hold the ABS wiring harness) with stainless items and replaced the hub-steering arm bolts… earlier cars had a few failures here, so it’s worth changing them for the later 10.9 grade ones for piece of mind.

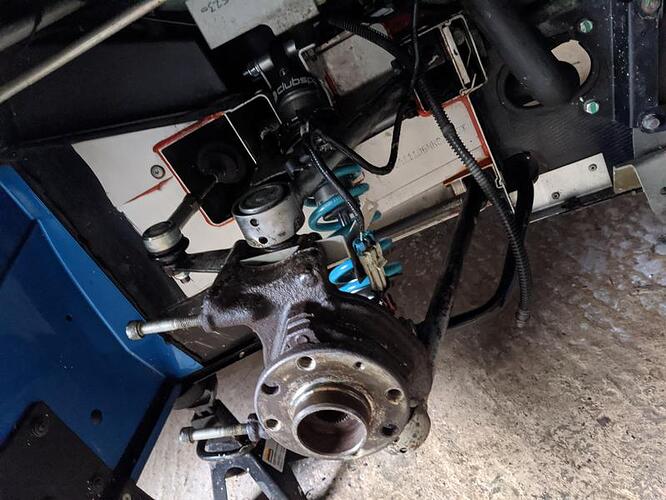

Also in the rear I removed the rubber brake hoses and replaced for some braided steel HEL ones I had. Can just about see it peeking in the background:

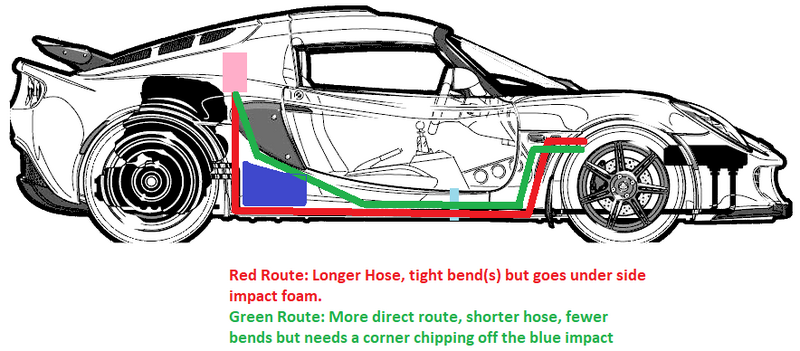

I can’t do fronts yet whilst the clam is on.

As for the brakes, I’ve had them all up on the bench for a nosey. It seems that I’ve chunked through a good bit of brake pad this year during my track antics. Before my trackdays started I put in some almost nearly new Pagid RS4-2’s (same compound I used and loved on my Elise). After finding the inside of my discs rotten I replaced the discs and got a spanking new set of RS4-2’s just to give me a clean start. The Pagid’s I took off still had 5.5mm of material so they’re in the toolbox for ‘get me home’ pads.

Since then I’ve done 3, maybe 4 trackdays and I’ve got the new set down to 3.5mm already… It’s well documented that RS4-2’s seem to perform worse and worse once they get below the half-way mark so the days are numbered on these. I’ve put the old 5.5mm deep ones back in for now till’ I decide what to do.

My Elise never really consumed pads at anywhere near this rate. I’ve done a lot (8.5) trackdays this year and 5000 total miles so perhaps I’m expecting a bit too much - but my Elise seemed to go on forever on the same set of pads and I did similar numbers of trackdays back then too. Perhaps the extra 5-10mph at the start of each braking zone is having an exponential effect… or maybe my driving style (more likely) needs adjusting. Either way, I think I’ll consider some big-boy pads that are perhaps a little more track focused at the expense of my disc life or day to day usability (noise/dust/etc).

With pads and pins out I gave all four calipers a good cleaning, and replaced the anti-rattle pads in the carriers.

As with the wishbones, these calipers with their ‘unfinished’ look often start to look crusty after a few years but these ones are still looking great - so they can avoid the hammerite treatment for this year.

The rears however have splits in the inner-slider boots. Nothing major but I’ve ordered a refurb kit so I can swap these over and give all the sliders a good clean.

All pistons and sliders are moving nicely, so overall a healthy setup.

Somewhere between that lot I got a nice present from the North Yorkshire Lotus Owners Club in the form of our 2020 club calendar, and a particularly nice choice for May…!

That’s about it for now, got some new goodies to unbox and then it’s time for the clam to come off… more updates to come soon.