As always, I am mystified by a lot of the technical aspects of this but as a “whodunnit, whatdunnit”, it’s as enthralling as a detective novel.

Great to read and hear of the cooperation offered by Exigers. And, once again, highly impressed by the methodical Fonzey. Hope you are proved right on all counts.

Meanwhile, my biggest problem has been the failure of the wipers on Mrs T’s TT during a downpour of biblical proportions. Required AA tow home ![]()

TRACKDAY UPDATE!

After the “VTEC Clatter” debacle I was all ready to service my Civic (which hasn’t moved since February) for the Blyton trackday I had booked on Sunday. After finally getting satisfaction that the car was healthy, I switched back to Plan A and got the Exige prepped… which consisted of a quick wash and setting the dampers up (7 clicks from hard all round, for the record).

I also noticed something which predates the new ECU, my IAT’s seemed to be recording 10degrees higher all across the range. I checked back on some old ODB logs I took earlier in lockdown and sure enough on an 18degrees ambient day, the IAT’s were 28degrees the moment I started the car. With the EMU I could now log this a little better, so took the IAT probe out with the log running and blew on it, sure enough the temp went up. I then sprayed it with contact cleaner, temp went down. When it dried/evaporated off - it settled back at ambient temperature… problem solved? :lol:

/Yawn, yes I know it’s Blyton again but options have been really limited this year. I had “store credit” to spend from cancelled Angelesey (x2), Cadwell and Oulton and Blyton always seems to be on the dates I can make with availability. Still, it’s good to benchmark myself and the car against a known quantity I guess.

The car didn’t miss a beat all day, I did take the laptop and had fun checking on various logs between sessions. Proper geeky stuff really and I felt like a bit of a berk in the paddock, but secretly I was loving it :mrgreen:

Some statistics:

Ambient: 16-18degrees C all day

IAT: Averaged in the mid 30’s and peaked at low 40s towards the end of a session.

Gearbox temps: 80degrees when up to temp on the motorway cruising at NSL, peak track temp recorded all day was 103 degrees.

There was some really sexy kit in attendance, four(?) Atoms, some radical things and a BAC Mono! Trackday royalty!

As for my car, it felt quick - no real gremlins all day and it showed no signs of slowing during the sessions. Peak speeds certainly are up from previous sessions but overall laptime (based on video, not timing!!) is still down by a second or so on my best from Blyton. Reviewing video afterwards and it’s just a couple of corners that I’m still not carrying as much entry speed into since I was on the OEM bilsteins. I know most people will swear that coilovers immediately drop 5seconds per lap, I’m more realistic/honest and frank about the fact I’m still chasing a setup that I’m comfortable with.

Don’t get me wrong, I love the Nitrons and the variance in damping I can achieve - I just need to keep working on a setup that suits my style, my style being very much dependent on confidence rather than ultimate grip. In the right hands my car probably IS several seconds faster, I just don’t have those hands :mrgreen:

I’m also not saying that the car is a wayward deathtrap, the front end is just too strong for me - it’ll turn into just about anything, and I tend to spend a lot of time waiting for/anticipating the rear coming round on me as a result, subconsciously this is causing me to turn in too early in a few places rather than just leaning on the car and 'chucking it like I used to do with my Elise. This is good news really, as I’m still fairly ‘central’ in my range of adjustability and if anything the S2 chassis will bias towards understeer - so it should be easy enough to dial out a bit of front end to give me some warning signs in future. My biggest failing is not adjusting during the course of the trackday, I just hammer on and try to drive through it.

I have a few ideas starting with more adjustment of my shocks during a day but I’m also coming round to the idea of a thicker ARB in the front to both protect my arch liners a bit more and to bring the bias of the car back to a bit of understeer - plus it’s easy to remove/revert if it turns out to be a disaster.

The new power delivery is noticeable, there’s a few areas at Blyton that previously I knew I could just mash the pedal at lower RPM and let the duller power curve carry me through a corner without upsetting the car too much, now I need to be more careful - through the faster Port Froid particularly I had to be a bit more delicate through the direction change, added a new challenge though and was fun to take on.

Only other niggle is that the brakes are still vibrating when they get warm. I’ve bedded in so many times now, but just can’t get it right. It’s not really slowing me down anymore as I just ignore it, but it’s a bit annoying. They don’t vibrate when going for full anchors-on mode, only when I partially use them from higher speed when trying to scrub a little bit off.

As Blyton is getting so samey, I had a play around with GoPro mounting positions and got some good footage from the rear number plate plinth. It captures a soundtrack of my car that I’ve never heard before as the cockpit is just dominated by SC whine which I find quite tedious tbh…!

https://www.youtube.com/watch?v=IiAakS8--SI

You had me right up to the last line …

Great write up Fonzey as usual. It sounds like I want more of your alignment as I find the front washes out a bit on my Elise

Had an opportunity to take the car out yesterday for a rare non-trackday event. Performance Autocare in Knaresborough put on a meet for coffee and pork pies, so would be rude not to toddle over - especially as Jonny @ Performance Autocare had been so helpful in trying to isolate the “VTEC rattle” a couple of weeks ago.

Some nice Exige content in attendance across all generations, and good to catch up with a few characters too.

Also had a fiddle with traction control on the drive over. By RRR’s own admission the RPM based strategy available with the OEM hardware is very limited - but since it’s functionality that I’ve got, I at least one to know it’s there and working if needed.

RRR had it setup in a very base sense, but it needs calibrating - quite difficult to do without having access to a wet skidpan or something but I could at least look to see if the base settings were working ok. What I found was that this is kicking in on dry roads (albeit cold tyres, so tiny amounts of slip) in a straight line doing 2nd/3rd/4th gear pulls - so it’s clearly far too aggressive.

The way in which it kicks in is much more subtle than the OEM Lotus approach though, it seems Lotus cut spark as part of their TC strategy which leads to the ‘pap pap pap’ soundtrack as it engages. The EMU allows for this to be replicated, but also offers a fuel cut approach which seems to be the preferred option of higher end TC systems such as Racelogic etc for the longevity of the catalyst if nothing else.

So I clearly need to reduce the sensitivity of it so it’s only stepping in for ‘proper’ slip events, despite the ABS S2 cars having wheel speed sensors at all four corners - the ECU/loom only receives speed data from one (NSR) so I can’t use axle speed differential for detecting slip (ECUMaster do have an addon for this though if proper TC is desired) so instead I need to use ‘RPM Gain’ for detection, which is pretty basic really.

The metric tracked by the ECU is “dRPM” (delta RPM = current change in RPM, if it spikes up in such a way that the current speed/gearing should not allow - then this is interpreted as slip). On an open diff car this is particularly useless as you’ll almost always get a spike in RPM during accelerated corners due to the inside rear spinning up. For that reason I won’t invest too much time into this, as realistically TC is never going to be used on track - but maybe if I one day end up with a diff on a wet trackday, it would be good to know roughly how this stuff works.

The ECU also has the capacity to take up to 10 positions from a rotary switch which applies a multiplier to the dRPM figure to either increase or decrease sensitivity. That same sensitivity adjustment can be made via a laptop so I could still probably experiment with it a bit. I think for now I’ll manually change the sensitivity until I find a point in which a dry pull through the gears is not causing TC intervention, then I know I at least have a half decent baseline that might save me if I have a brainfart on a wet road.

Quiet week on the spanners, just used the car for some menial tasks like collecting croissants on Sunday morning…

and a nice evening clean.

…but I couldn’t keep the car in one piece for too long could I?!

I posted about an issue a while back (before the new ECU) in which the car would occasionally stall when cruising up to a stop in neutral or with the clutch in, revs would just drop too far below idle target and the car would shudder and die. The new ECU ‘fixed’ this in a sense, in that the revs still fall but the ECU jumps in and throws a load of timing/fuelling correction at it to prevent the stall and re-establish the idle but it still feels a bit jarring to be honest so I wanted to hunt down the root cause.

I’ve spent some time remotely with RRR and I’ve expanded my learning a bit to make some incremental changes to the idle correction mechanisms to try and smooth it out (it feels a bit like a tank slapper at the moment, idle drops too low - ECU overcorrects, then it goes too high, ECU overcorrects, etc until it eventually settles down). We’re making progress on it but I don’t think I’ll be completely happy with it until the issue is sorted properly.

As the car is DBW, there’s not much at first glance that could be physically wrong. My Elise let me down once by the potentiometer in the throttle pedal failing, and the ECU trapped me in limp home mode for the duration of a 3 day trip around the Lakes :evil:, the research I did at that time suggested that the GM parts used for that potentiometer are known for going bad - so perhaps I’m seeing early signs of that… but as the issue is exclusively at idle, I’m thinking not.

As for the TB itself, there is of course another potentiometer with a motor and some gears - really simple stuff but I decided to take it off anyway for a look.

Other than sloshing a bit of coolant around, it’s not too difficult or awkward to remove even with the chargecooler plumbing in place. Removing CC and catch cans would have made access much easier though.

Once off the mechanism could be exposed and I’ve found a potential path to investigate.

There’s a small “stop screw” which the mechanism comes to a rest at. The butterfly is spring loaded so will always try to default to full close but that screw prevents it from shutting 100% (as otherwise the car would stall at idle all the time).

However if I tweak the flap a bit with my hand, there’s some slack in the mechanism that means it’s closing slightly further than the motors “rest” position. I video’d it here to try and capture it better:

<LINK_TEXT text=“https://www.youtube.com/watch?v=-WfsIj3 … zeyOnTrack”>https://www.youtube.com/watch?v=-WfsIj3VppY&feature=youtu.be&ab_channel=FonzeyOnTrack</LINK_TEXT>

It’s very close, but perhaps winding that screw in half a turn would take that slack out and give the butterfly a slightly more “open” closed position.

Once I understood a bit more about how the mechanism worked, I did a bit more googling and found a thread here which describes exactly this: <LINK_TEXT text=“https://www.lotustalk.com/threads/solve … st-1651381”>Solved my Exige stalling issue! | The Lotus Cars Community</LINK_TEXT> so it’s certainly worth a try.

The coolant lines will make constantly removing/refitting annoying so I’ll probably loop those for now. I know a lot of the Celica guys bypass the TB coolant anyway in a vain attempt to lower intake temps so the car won’t blow up without it.

I also discovered a small support bracket for the TB was broken (before I touched it, honest!!). Not a big deal, I doubt it’s particularly load bearing but it’s always a possible source of rattle so I’ll get that replaced once I can find a non-Lotus premium part number to stick into eBay…

No conclusion to this yet, will do a bit more homework before I adjust anything and will report back with results (or lack thereof).

I don’t believe that screw/stop is used once the engine is running. I’ve had idle issues with a tuned stock ecu and followed the same post on Lotus Talk to adjust the stop point. I tried several adjustment points and none changed my idle problems. When I logged data from the ecu it appears the throttle never even paused at that stop point. I verified this by noting the throttle position % open prior to starting the car. Once the car was started the % open was always less than the value I had recorded. This leads me to believe that stop is only used during starting to allow enough air to enter the engine for it to fire up. If the throttle was completely closed then it would be difficult to get enough air into the engine during cranking.

Best of luck with your idle problems. I had hoped the EMU black may provide a fix for that issue, but it’s sounds like it may just be a Lotus issue…

Cheers Emp that’s useful info, I also wondered that the stop may not even be relevant with the car running as I’d imagine the ecu keeps the throttle more open than that anyway.

Eh well, it’s worth a go for the cost of half an hour. If I don’t get anywhere I can at least say I’ve checked it and get back to trying to smooth the recovery out a bit with the EMU.

I followed this through by adding barely a turn onto the ‘stop screw’ after applying some loctite to keep it in place afterwards (Toyota gobbed the whole log with epoxy which I had to chip off first).

First impressions were fairly late at night, so limited to just firing up the car and making sure it didn’t spray coolant everywhere etc. Revs seemed a little higher than usual, but barely - and it was a cold start so possibly I was just looking for differences that weren’t there.

Today I took the car out for lunch (except we forgot to buy lunch) and tried to get a feel for the car on the road. I kept extending the test drive because I couldn’t replicate the previous fault and I was determined not to get a false hope.

After half hour or so of mixed driving, I forgot about it completely and I’m pretty sure I’ve at least drastically improved it if not fixed it completely. The stop screw could be a complete red herring, perhaps I just inadvertently fixed a slight air leak that I didn’t know I had - or perhaps atmospheric conditions today are just favourable… who knows, but the car felt robust enough at idle when coming to a stop.

I did a bit more testing on the driveway just revving it up and seeing how it behaved coming back down and it’s probably not yet perfect - but perhaps close enough that the rest can be smoothly handled by the ECU now.

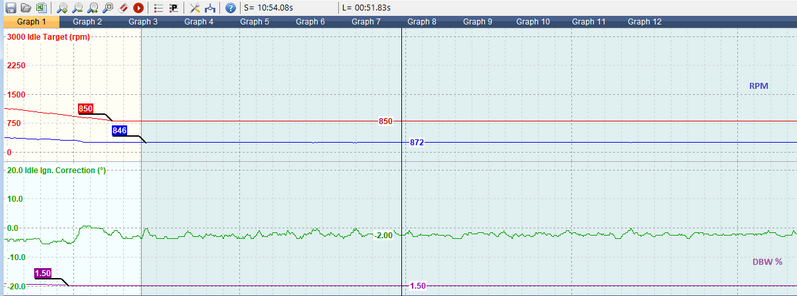

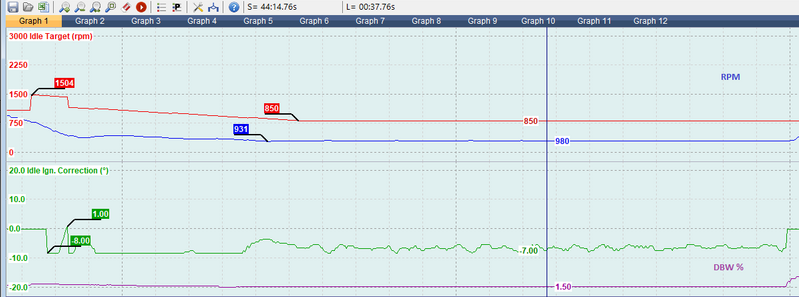

I did some logging of course, and there’s still some follow up activity. My idle has definitely increased by around 80-100rpm, you can see from these logs here (one taken from a few weeks ago)

OLD

RPM is within 25 or so of the idle target and the ECU is retarding ignition by 2deg to try and bring it into line.

TODAY

RPM is a good chunk higher and the ECU is maxing out it’s configured ignition at -7 deg in a vain attempt to get it down (I guess lambda targets are keeping it high).

On both you can see the DBW reported % is at 1.5% - suggesting my physical adjustment has had no bearing on what the integrated potentiometer is reporting. Perhaps it auto calibrates itself somewhat? Or perhaps (as intended) my adjustment was just within the slack that already existed within the mechanism?

I’m now considering raising my idle target up to 950rpm in the ECU software just so that it’s not trying to hard to correct it back down. The car feels ‘comfortable’ at this idle point, no juddering or reverberations (people with stiff engine mounts will agree that certain rev ranges are to be avoided!!) and it’s not excessively noisy either. I’ll run my findings past RRR and see what they say, but only after a few more test drives to confirm whether this success is real or not.

I also took out the bracket that was broken and it’s turning out to be quite the mystery part, it doesn’t seem to show up on any of the Toyota or Lotus parts diagrams so I can’t find a part number to search for. It seems to connect the bottom of the TB to the swan neck adaptor used to connect the TB with the SC. It can’t be overly structural because it’s mounted via an isolation bobbin and it’s been broken for god knows how long. Luckily it’s “all there” as the bolt was in place holding the broken off piece, so shouldn’t be a big deal to get it welded up and refitted.

Hi Kyle! Just FYI, mine is set to idle at about 950rpm by RRR and I have no ‘stalling’ issues (which it previously did have when set to a lower idle rpm), despite having the Fidanza flywheel and lumpy cams. Since fitting bigger fuel injectors I don’t have the cold start problems I previously noticed either… although I’m worried I’m overfuelling now so need to take it back to them! ![]()

Interesting cheers Matt, I just spoke to @andybond and it seems his tuners on his ECU went the same way too.

I guess I’ve gone a long way round of changing the idle, I could have just done it in the ECU without lifting a spanner but at least I’ve given the TB a good check over and clean out. ![]()

With Covid restrictions ramping up again my next trackday of Anglesey at the end of October was feeling threatened so I wanted to try and get out in September. Everything has been fully booked all summer so I put a shout out onto a FB group which is intended for the buying/selling of track time and I got an offer of Croft on tuesday this week. I snapped his hand off, and after not hearing much over the weekend we finally got it confirmed with the TDO on Monday.

The car didn’t need much prep, just lobbed my tools in the back and packed my helmet then I was off! With not much time to think ahead, for the first time ever I didn’t have weather anxiety on the run up to a trackday as the forecast was bob on. Nice early start as the sun was just starting to cut through the mist.

Not many Lotus in attendance but I quite like the colour of my paddock-mate.

(Supercharged K-Series btw, fairly rare configuration nowadays but seemed to go well!)

As this was technically a “bonus” trackday I had decided I’d use it as a day to experiment with suspension setup, something I’m usually reluctant to change mid-trackday because I don’t want to lose track time to a naff setup or get myself lost in iterations. I normally stick quite close to the ‘middle’ of the Nitron settings, hovering around the central settings and just tweaking in small increments in an attempt to alter the balance of the car a bit but today I decided I was going to run much stiffer and see if I could find the point where things got too stiff.

My starting settings (taken from my last Croft day) was 8/8 from hard (total of 20 clicks available) and I did the first couple of sessions like this. Car felt good, but maybe felt too soft at the rear as the car was pushing on a little bit and I think I was lifting the occasional front wheel… in fact, I know I was :mrgreen:

Through buying a cancellation I’d also inherited a tuition session in the mid morning which was a great use of 20mins. I’ve never felt like I had ‘Tower’ anywhere near decent and so we focussed on that and got it a bit better, but I know where to keep improving there for next time. Other feedback was generally strong, just said there’s loads of time on the table through commitment in the 'Esses which I’m well aware of, but comfortable with my commitment levels through there for now :mrgreen:

I popped out at lunch for fuel and food and bumped into a fellow petrolhead (not linked to the trackday) in a Clio 182 trophy - don’t see those too often so had a good chat about all things cars before hurrying back to the circuit.

After lunch I’d brought the settings to 5F 2R (from hard) and I remained like this for the rest of the day. Traction felt really good like this, particularly on the hairpin - I still can’t be too heavy footed through there but it was loads better than earlier in summer. The only hint I got that things were too stiff in the rear was that I’d occasionally feel the rear hopping a bit when entering the hairpin too quickly, quickly followed my a small slide on entry, I found slowing things down on entry and being more aggressive on exit was an acceptable response to this.

In hindsight I think I’d have like to take the fronts a bit stiffer. I didn’t realise on the day that my F and R adjustments were a few clicks apart as I’d been making small incremental changes through the day. If I realised it was 5/2 I’d have tried at least one session with 4/2 to see how things changed.

My last two sessions were both brilliant, but I could feel the brakes starting to struggle a bit. I initially thought it was just the fluid getting too hot because the pedal was just going a bit long. I got a bit of footage from the penultimate session:

<LINK_TEXT text=“https://www.youtube.com/watch?v=OytIxLI … zeyOnTrack”>https://www.youtube.com/watch?v=OytIxLI31wo&ab_channel=FonzeyOnTrack</LINK_TEXT>

On the final session I pretty much had the track to myself along with a race prepped MR2. I was obviously a fair bit quicker on the straights but it was clear this guy had a few things to teach me about commitment through the faster bends so we settled in for a few laps, I would give him space on the straights and then we’d follow through the rest of the lap quite closely. We then swapped places and did similar until his tyres faded and my brakes felt like they’d had enough. Unfortunately the GoPro batteries died quite early into this session so didn’t capture any of the good parts, but despite being “not the fastest” laps it was great fun following through and pushing each other on a bit.

As the car cooled down on the way home the brakes started making all sorts of weird and wonderful noises - analysis the following day suggests I got about as much as I could have done out of the RS14s…

These have lasted 5 months and 5 trackdays, I don’t think that’s TOO bad but I’d like to try a different pad next to see if I can find something a little harder wearing. Even if it punishes my discs a bit, as currently they look unharmed in 2 years and 10-12 trackdays.

I’ve raided my box of ‘get me home pads’ to keep me going for now (stuck in the EBC red stuff I got with the car and OEM Brembo rears…) while I canvas some opinion and take a punt on the next brand.

On the ECU front, nothing really to report - car pulled hard and fast all day. I monitored gearbox temps again and it feels like the temps are “settled” at 80degrees C, that seems to be the status quo with regular road driving, then once on track it seems to gain approx. 2 degrees per minute and my sessions usually average 10mins of ‘hot lapping’ which is consistently seeing me peak at 100deg. On the later sessions I had a longer one, and this pattern continued up to 112-113 degrees so it’s reasonable to think that a 20-25min session (way beyond my physical capabilities…) would see temps spiking to dangerous levels.

IATs didn’t go higher than low 40s.

You were flying on that session! Looked really impressive.

Good news about the gearbox temps as well. Great information

you will not go wrong with performance friction pads, bit dusty, but the best pad i used on my Exige and I tried loads over 10 years

![]() According to GoPro I was going about 3 sec quicker than earlier in summer.

According to GoPro I was going about 3 sec quicker than earlier in summer.

So far everyone is making recommendations of whatever they use, so I’ve had pretty much every brand recommended of course ![]() The PF however seem to be the one recurring one, and I’ve also got a friend who is getting about 4x as track mileage out of his PF08s than I am on my RS14s so they’ve got to be worth a shout…

The PF however seem to be the one recurring one, and I’ve also got a friend who is getting about 4x as track mileage out of his PF08s than I am on my RS14s so they’ve got to be worth a shout…

Just trying to get my head around the numbering of the PF compounds now ![]()

PF01 front and PF97 rear I think, but I might be hopelessly wrong, in fact probably ignore me completely, I used those for 4 pots up front and 2 pot rears! Or I might still be right.

Calling JDS to remind me of what is the right compounds, he used to always supply mine…

As per my thread in the tech section, I suspected my aux belt tensioner pulley may be struggling a bit. In hindsight it was probably my imagination but the soundtrack of my car at idle had subtly changed after Croft, it seemed to be coming from the belts and the tensioner had some signs of weapage.

I can only assume it’s time served ‘beyond optimal range’ contributed due to the alternator not being bolted up right, and my belt requiring extra tension for all those years/miles but maybe it’s just one of those things. In any case, I had two options:

1- Replace the whole unit (damper, arm and pulley)- pricing starting at ~ £120 for SKF or many times that for Lotus/Toyota, would also mean undoing engine mounts and lifting the engine for clearance.

2- Replace just the damper, not available through Lotus/Toyota but SKF do one for £40.

Obviously went SKF, mainly due to the easier swap rather than the cost.

Whilst the aux belt was off, I ran the car for a few seconds and I think the noise was still present… I say think, because I’m now starting to believe I was being overly attentive to something that probably has always been there…

Anyway, the old one was definitely ‘passed it’ because when I compressed it on the bench with a g-clamp, gunk came out of it.

With that done, onto my brakes. I posted the photo of my Pagid RS14 remains after Croft and I thought I’d give all four calipers a good clean out ready to accept the replacements when they come. I had to pop a double take when I saw the OSF disc…

![]() This could actually be good news. I’ve never been THAT happy with the brakes since fitting RS14s, their ultimate performance was brilliant, far better than the RS42s but on partial pressure they had horrible vibrations, that no amount of bedding in (or trackdays) seemed to resolve. In hindsight that was almost certainly down to the disc itself, before it cracked I imagine it was probably not running true on its way to failure. It also explains the heavier pad consumption on the OSF corner, the others are still ‘almost dead’ but I could have maybe got one more trackday out of them had the wear been even.

This could actually be good news. I’ve never been THAT happy with the brakes since fitting RS14s, their ultimate performance was brilliant, far better than the RS42s but on partial pressure they had horrible vibrations, that no amount of bedding in (or trackdays) seemed to resolve. In hindsight that was almost certainly down to the disc itself, before it cracked I imagine it was probably not running true on its way to failure. It also explains the heavier pad consumption on the OSF corner, the others are still ‘almost dead’ but I could have maybe got one more trackday out of them had the wear been even.

So hopefully now with fresh discs and pads, I’ll be well on my way.

As for the replacements, Seriously Dave to the rescue - no attempt at all to blame the failure on me/track abuse/poor maintenance/etc - just a straight up “that’s not right” and replacements were with me 18 hours later. Failures happen, but it would be so easy for a vendor to hide behind the “not covered for track use” bollocks that certain other vendors do around the Lotus market…

Obviously the replacements are different, they’re just belled versions of the same blanks which were in stock and the single piece ones were not.

Now, just pads to decide on…

Woah that’s a bit scary, don’t want to imagine what it would have been like if that crack had propagated right though.

I’ve had crack from the drillings on drilled discs before, but never anything like that! I ended up only running AP discs on my Exige, I must admit though the Clio gets Bembo high carbon discs that are solid, nobody really seems to do a decent package for the Clio and whilst my 4 pot Brembo callipers are ok, they are heavy and poorly designed against the AP you get on the Exige. For instance I can only just squeeze 300mm discs under 16s on the clio, but the exige I could run 315mm, this is all down to calliper design.