Mine is now supercharged, so not sure it will be the same, but will see what I can find out… could you not give RRR a call… sure they would be able to advise ? (again sorry for thread derail @fonzey)

No apologies needed, I like discussions!

Already tried one remote session with RRR, helped a little, but just not right…

Dropped the gearbox oil and engine oil this weekend, well that took an hour - and then thoroughly degreasing my floor, underside of my car and pretty much all of my possessions (including the cat) to get rid of the gearbox oil smell took the rest of the time up… ![]()

Here’s my new drain plug for the gearbox:

Sensor is just cabletied up out of the way for now, but once the EMU goes in I’ll have it hooked up and reporting gearbox oil temps. Based on what I see will influence what happens next, but I’m fully expecting to be dropping the oil again in the near future for an oil cooler install. If anyone has any pictures of a gearbox cooler install, I welcome the inspiration for packaging/positioning etc. ![]()

While I had the car up in the air and I was making a mess I decided to tidy up an element of the charge cooler install.

I previously had the pump mounted along the bulkhead trim which was nice and tidy and made for a short wiring run.

The downside to this was that the lowest ‘drain point’ I had at the rear of the car was essentially the header tank - meaning any work on the charge cooler system just made a massive mess, filling my alternator with 5 litres of coolant isn’t something I wanted to be doing too often… Clearance between the pump and SC was also very tight so I was a bit nervous about engine movement damaging the pump (lack of witness marks suggests that wasn’t an issue in hindsight).

I also had a bit of a window rattle at certain RPM, so I had half a suspicion that the pump was causing it.

As an alternative location there’s loads of room in the side pod/rear wheel arch area so I thought by moving it down there I could retain easy access for maintenance but also give me a convenient place to drain the system if I need to.

I had to extend the wiring a bit, but no big deal there (as you can see I over extended it a bit…). Conveniently there was a clam fixing bolt right in a good place for a p-clip on one of the hoses, so made use of that.

The good side to this, my window rattle did indeed get fixed - so pretty chuffed with that. The downside is that the whine from the pump became very audible all of a sudden, not helped of course by the fact the pump was effectively mounted to my lug 'ole. You could just about hear the pump over the engine idle and it only took a short drive to get annoyed by that.

Luckily the fix was an easy one, I picked up some M6 isolation bobbin things and mounted the pump via one of those. The pump is now inaudible with the engine running, and has the added benefit of adding clearance between the hoses and the bodywork. ![]()

Pump can now be unbolted/drained from the side pod if needed (don’t tell the local chavs that).

Excellent work.

I always prefer jubilee super clamps on water pipes but that’s just a personal preference ![]()

I save my gucci clips for the engine bay where people can see them ![]() I’d actually be a bit nervous using t-bolt clamps for this, the pump nozzles are only plastic and it’s harder to gauge tightness with them IMO.

I’d actually be a bit nervous using t-bolt clamps for this, the pump nozzles are only plastic and it’s harder to gauge tightness with them IMO.

I picked some new(ish) 225/45/17’s up for the rears this weekend. Got in touch with a lad who has a tyre bay near Sheffield and he buys a load of Avon ZZRs from various race series’ that have done a session or two.

I know part worn tyres are a bit of a controversial topic but I’ve bought them pretty much exclusively since I started doing trackdays, so I’ve normalised it in my head helped by the fact I’ve probably saved 5 or 6 grand in that time ![]() … Got 4x 17’s for £280 and they have just under 5mm tread on the inside shoulders and just under 6mm on the outer edge, so barely used at all. Also date coded late 2018/early 2019 so no issues there either. My last set I bought part worn with a 2016 date code and they’ve lasted me about 12 months and 6 trackdays, so it works out pretty decent.

… Got 4x 17’s for £280 and they have just under 5mm tread on the inside shoulders and just under 6mm on the outer edge, so barely used at all. Also date coded late 2018/early 2019 so no issues there either. My last set I bought part worn with a 2016 date code and they’ve lasted me about 12 months and 6 trackdays, so it works out pretty decent.

The only thing I’m not sure about is whether to keep the two spare 17’s that I bought for next year, or sell them on now - as they’re also dated 2018 (albeit late 2018) they’ll already be 2-3 years old by the time I come to need them.

Whilst messing around with my chargecooler plumbing I noticed something odd with the nose bracket on the supercharger, in that it didn’t seem to be attached to anything.

It’s really well hidden and incredibly hard to see without sticking your head in the sidepod, but I snapped a photo with my endoscope:

I initially assumed there should be a small bracket between this bracket and the alternator, but thanks to confirmation from seriouslylotus I realised the alternator must have swung down from its proper position. Luckily the belt tensioner must have taken up this slack in its stride, but certainly this wasn’t right.

With the car jacked up and sidepod off I got a better look.

Fix is a cheap one, M8x45mm bolt and a 15mm nylon spacer.

Oh, and loctite…

When I took the belt off the alternator, it had no free movement in it at all - so it wasn’t flapping around around the axis of it’s one remaining bolt - but I guess the strain on the belt had gradually over time pulled the alternator down to the point where it can’t go any further (as there’s engine in the way) which probably aided the tensioner in gradually taking up the slack. Had this suddenly have flapped down I’m sure I’d have lost a belt at some point in history.

I loosened off the bottom bolt and it was fairly easy to slot the spacer/bolt in and tighten everything back up again.

Getting the belt back on was much harder than I remember from previous jobs, so I’m certainly working the tensioner harder now! How this came to happen I’m really not sure, it’s such a hidden area of the engine bay that I probably don’t have any old photos to check back on (though I will check…!). The car did get a new supercharger back in 2012, the circumstances around that I’m really not sure but perhaps it was never fitted properly? Or on the other hand the bolt could have fallen out last week, I really can’t be sure.

That’s a pic I took when I first bought the car, I dropped the dipstick and spent hours looking for it - it turns out it had landed in my sidepod…! Anyway, alternator still sat there chillin’ on his own… ![]()

That’s a pic I took when I first bought the car, I dropped the dipstick and spent hours looking for it - it turns out it had landed in my sidepod…! Anyway, alternator still sat there chillin’ on his own…

Ha! Whats the chances of that staying in there.

Have you found any of the 18 sets of 10mm sockets I have lost over the past few months in there?

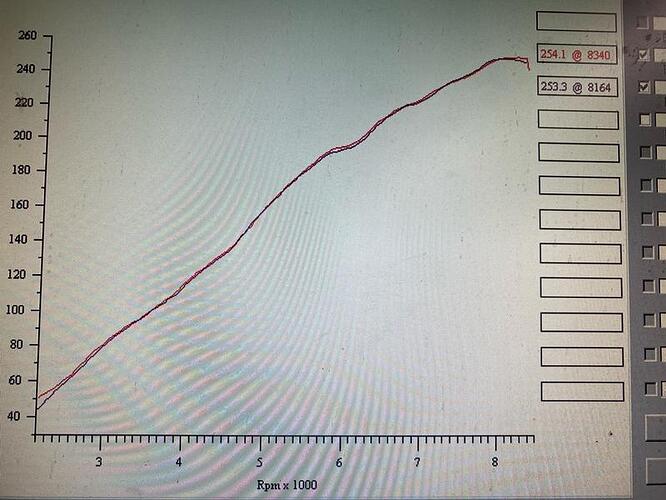

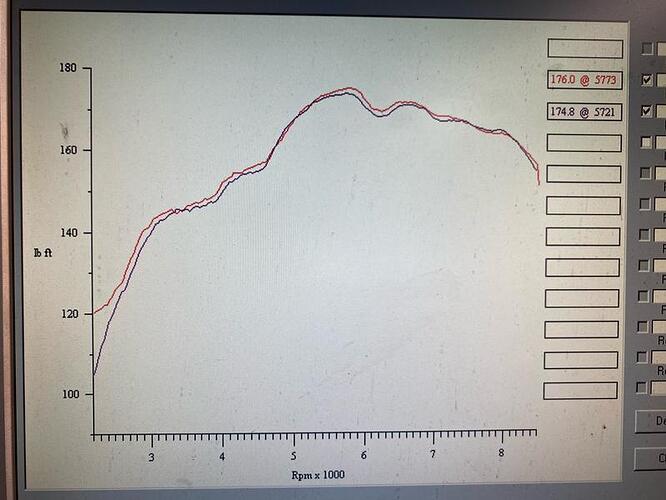

I have some dyno graphs (from March!).

Timely really as the car is in for mapping this week, but although these were taken in (much) lower ambient temps on a different day on a different dyno (rolling road vs hub at RRR) it’s still the only real reference I’ve got for the pre-2bular iteration of the car.

Headline figures will be redundant really, but at least I’ve got an idea of what the visualisation of power delivery looks like.

The two runs plotted represent the first and last of the power runs, so is a good illustration of just how effective the charge cooler was back in March and cooler temperatures.

ECU/Mapping update!

I collected the car on Saturday and although I’ve had very little time in the car, I can at least report on some bits! First off a note on RRR Engineering, very professional from the beginning with good communication, time/booking management and generally just see well organised. All attributes which are not as common as they should be in the car tuning world…

We agreed up front for the to have the car Saturday to Saturday, makes the logistics easier for me and allows them to do proper cold start tuning etc. Other than bolting in the ECU and mapping, I also asked them to supply and fit the ECUMaster EDL1 data logger unit and wire in my gearbox oil sensor that I recently added to the drain plug.

On handover data Roberto was happy to chat for ages about my plans/trajectory for the car and discussed any gremlins I felt the car already had.

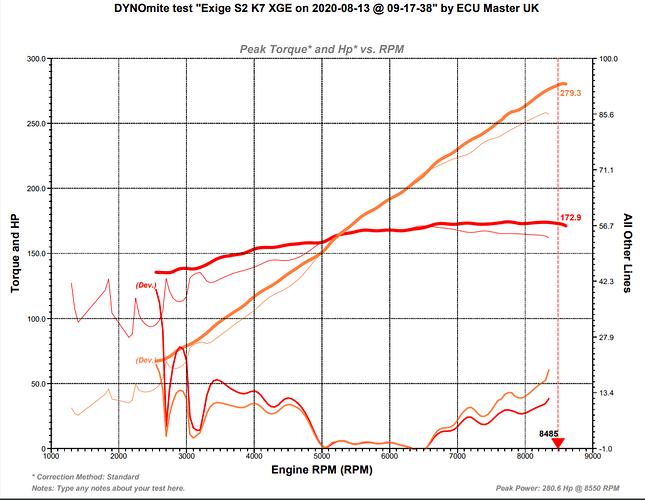

By end of Monday they had benchmarked the car with its ‘as-is’ setup just to make sure I didn’t piss fuel/coolant/oil all over their workshop and the results came back as expected of “260ish”. This matches my butt dyno opinion that neither charge cooler or 2bular system added much of anything on the 260 ECU.

By end of Wednesday the new ECU was in and the base map setup, I got a cagey e-mail back saying “yada yada hottest day of the year, intake temps, small power gain” etc but that they intended to do proper power tuning early on thursday.

I got some results by midday and they sounded both wrong and terrifying. I was told the car was doing “276ish at the hubs”. AT THE HUBS… factoring in 15% or so for transmission losses that would put my pub figure way into the 300s, a figure that I was almost certain my hardware wasn’t capable of (stock pulley and 440cc injectors). I queried it of course, but there was only so much I could argue without sounding like an internet know-it-all so I just let it lie, and assumed there was a terminology mixup and that the car made 276 AFTER loss adjustment, which is much more in line with expectations. They even said “276 at the hubs so will be 320+ at the fly”, so it’s not just me mishearing terminology!

My main fear was that if by some miracle they did get 320+ out of it, gearbox would go from marginal to flat-out suicidal. I’ve already paid for a gearbox upgrade in my head, so I’m comfortable with it happening eventually… but not imminently!

A few hours later the final figure came in of 280bhp, again quoted at the hubs and this time printed on a graph.

I know from a recent posting of a RRR graph from another Lotus owner that their graphs are usually posted ‘at the hubs’ which added up to what I was told verbally, but there are a couple of giveaways that suggest it has indeed been adjusted and is actually 280bhp ATF.

- you can see the original benchmark run on it which is around 260bhp, if these were at the hub figures that would have been more like 215-220bhp.

- the torque figure appears to be pre-adjustment (at the hub). Suggesting maybe BHP has been adjusted but torque has not?

In any case, this is probably just a comms hiccup between the guy doing the dyno/map and the guy communicating with me. If they usually do dyno graphs pre-adjustment then it’s understandable that he would relay that info to me as such.

Anyway, none of that is really important in the end - I was expecting mid 270s, so 280bhp is a result and is right on my imaginary threshold for the gearbox. I fully expect it to fail at some point, but I think I’d be unfortunate for it to go bang immediately. We’ll see eh.

After giving myself a panic induced headache at the thought of a 320bhp C64-eater, I decided to just see how the car drives and then take it from there.

Ignoring the figures, the torque curve looked promising, as it went from a hill to more of a ramp steadily increasing up to the limiter. In both BHP and torque the midrange from the benchmark run yielded minimal improvement, so perhaps the CC/Exhaust can take some credit for that - but the new map added clear gains low down and high up. Apparently the 440CC injectors peaked at 80% duty, so a nice safety net there - but any smaller on the pulley and 550’s would be needed which matches what I expected.

On to collection day, had a quick walk around the car - paid my bills and hit the road just in time for the skies to open…

This basically meant I didn’t go above 4k RPM until I beat the rain and got within 20miles of my house, 2 hours after collecting the car. ![]() Impressions on the A1 though were very positive, car had an urgency at low RPM that it certainly didn’t have before, pulling round slower moving traffic in 6th felt great.

Impressions on the A1 though were very positive, car had an urgency at low RPM that it certainly didn’t have before, pulling round slower moving traffic in 6th felt great.

Once onto dryer roads I gave the car a handful of ‘pulls’ and was impressed with the result, the power delivery has always been linear but the tail-off of torque is something I never noticed before, but was definitely a feature in retrospect. The car now pulls rampantly all the way to the top, each gear feels like it’s been “promoted” and I imagine 2nd gear will be all but redundant at all circuits now due to the potency of third and above. For the record my butt dyno would say its closer to 280ATF than it is 320bhp, so that puts that to bed.

Despite that positive start, I think there may be a bit of ironing to do. The car seems to have some issues at low RPM whilst coasting to a stop. I think I’ve mentioned it on the thread before, but even previously on the Lotus ECU I had issues with the car periodically stalling when coasting to a stop, the revs would dip below idle and the car would just die unless I was quick to poke the gas to revive it.

I did report that to RRR, and the EMU is clearly responding well to this - as I no longer stall, but the initial drop in revs is still happening, the EMU just jumps in and recovers it for me… so an improvement yes, but still feel there’s a root issue somewhere, possibly mechanical or a vac leak maybe? Not sure if the DBW cars have an idle air control valve or something similar, but I’m sure I can do some homework and find some parts to dismantle.

Aside from that I noticed that revs are a little slow to fall when dipping the clutch in first gear, which makes the car feel a little ‘clumsy’ when not used to it. This may have been engineered in to mitigate against the stalling detailed above - but it’s something I can discuss with RRR once I get some more mileage done.

I spent the rest of my weekend fiddling around with the ECUMaster software, and started playing with the logging. I’m going to LOVE this once the car gets back on track!

Gearbox temp sender seems to be working fine, and was logging temps of 79/80deg C all the way home. Temps didn’t seem to leap up when the car is used enthusiastically like you would see with engine oil temps (or intake air temps) but I at least now have a benchmark, so can see how hot it gets on track.

Oh, quick note on traction control - for now the EMU is pretty much emulating the stock TC that I had, in that it’s on or off - and that’s about it. By RRR’s own admission it’s pretty agricultural and is certainly not suited for track use, but I have a couple of options for improving it if I want to:

1- Add a rotary switch at which point it becomes variable, perhaps I could find a sweetspot on a wet track in which it adds value. Again the logging stats for TC look really detailed, so would be interesting to see

2- Add some wheelspeed/CAN adapters and go full motorsport on it. Not sure exactly what that means, but almost certainly excessive for my use so probably something I won’t bother with.

Unfortunately I won’t be back in the car for a week or so, so need to wait to play with my toys later… ![]()

Nice update Fonzey I’m sure that is going to be a blast on track.

Interesting to hear the gearbox temps don’t really move when working the car more. I’m interested to see how much they move on a track day. My 944 gearbox used to get so hot on track that the diff characteristics would change. I never put a temp gauge on it but I did plumb a cooler and pump onto it.

Very nice results mate! Will have to talk cold start parameters with you one day, lol… I noticed you’re set to 10 degrees BTDC ignition, same as me - if yours starts nicely when cold then mine must have a problem with something related to fuelling rather than timing… ![]()

I’m not surprised the gearbox temps are static on the road, I only ever ran my cooler on track to cool the gearbox or to assist in warming the gearbox oil ready for the first track session. You will be amazed how much the temps sky rocket on track.

Those traces you have look almost identical to mine when I first went to 260hp charge cooler and exhaust with a map to match, as a rule of thumb, every 0.1" smaller on the pulley equates to ~10hp and torque across the entire range >2500rpm! So 310hp ish from the 2.9" pulley, but given correction factors etc. I always used to just say 300hp+ ![]()

Great thread!

Doesn’t the EMU black use a built in MAP instead of the MAF? Where did RRR tap for this reading? I always though the exige idle issues were caused by the long intake tract behind the throttle body. I’ve wondered if putting a sensor right on intake manifold would improve the sometimes wonky idle.

Great thread!

Doesn’t the EMU black use a built in MAP instead of the MAF? Where did RRR tap for this reading? I always though the exige idle issues were caused by the long intake tract behind the throttle body. I’ve wondered if putting a sensor right on intake manifold would improve the sometimes wonky idle.

RRR put a hose between the EMU Black’s MAP and the intake manifold on mine (done in March this year). Mine still showed stalling issues until they mapped it out - partly with an increased idle. I’m sure that if they had more time with my car they could get things better and better, but it’s dramatically better than the standard setup was on my car…

Nice update @Fonzey I’m sure that is going to be a blast on track.

Interesting to hear the gearbox temps don’t really move when working the car more. I’m interested to see how much they move on a track day. My 944 gearbox used to get so hot on track that the diff characteristics would change. I never put a temp gauge on it but I did plumb a cooler and pump onto it.

Yep the car was no slouch on track before but as ever I look forward to seeing how this development works out. I just need to resist the urge to actually spend time on track, and not squinting over a laptop between sessions ![]()

Very nice results mate! Will have to talk cold start parameters with you one day, lol… I noticed you’re set to 10 degrees BTDC ignition, same as me - if yours starts nicely when cold then mine must have a problem with something related to fuelling rather than timing…

I’ll take your word for it o the BTDC! I’ve only done one cold start so far and then have had to park the car up for a week anyway, so I don’t want to claim success quite yet, but early impressions look good.

I’m not surprised the gearbox temps are static on the road, I only ever ran my cooler on track to cool the gearbox or to assist in warming the gearbox oil ready for the first track session. You will be amazed how much the temps sky rocket on track.

Those traces you have look almost identical to mine when I first went to 260hp charge cooler and exhaust with a map to match, as a rule of thumb, every 0.1" smaller on the pulley equates to ~10hp and torque across the entire range >2500rpm! So 310hp ish from the 2.9" pulley, but given correction factors etc. I always used to just say 300hp+

Yeah I’m expecting the temps to creep up on track, not sure what my cut-off would be yet for oil cooling. From my research it sounds like gearbox oil is less dependent on a minimum temperature because it’s a closed system and doesn’t need to worry about evaporating moisture etc, but it still need a certain level of heat to meet optimum viscosity… whatever that is! I think once I have a cooler in place, I’ll manipulate the pump in such a way that I aim for 100deg max temperature… because y’know, its a round number!

As for the pulley, it’s tempting now as an option for cheap and easy power! I’m impressed with the 280bhp made on stock pulley and I can have confidence that SC is still operating in its sweet spot. I could have probably achieved this same power for much cheaper (add injectors/pulley and remove chargecooler/exhaust) but I feel happy that I’ve done things the ‘safe’ way. When the inevitable occurs and I end up spending on the gearbox, a pulley and injectors won’t be far behind…

Great thread!

Doesn’t the EMU black use a built in MAP instead of the MAF? Where did RRR tap for this reading? I always though the exige idle issues were caused by the long intake tract behind the throttle body. I’ve wondered if putting a sensor right on intake manifold would improve the sometimes wonky idle.

Cheers! Yes it used built in MAP, mine is tapped into the intercooler piping so I guess the MAF is now totally redundant (and hence ruled out as being an issue for the stalling). I’ve not had much time this week yet but I know for sure the cable throttle cars have an IACV that is worth a good cleanout… just not sure if the DBW cars retained that?! Other than that I guess I might have a trace of a vacuum leak, but as the car is running otherwise spot on - I find that unlikely.

the fuelling looks a bit… all over, did they not give you a separate fuelling graph which displays the AFR ?

a smaller pulley will generate more heat and intake temps will skyrocket, you will have a gain to start with but wont last as soon as it gets 60+ IAT the ECU will probably start to pull timing leaving you with less than you have now. (we suffer the same situation on the VX220 circa 300bhp on 2.9" pulley is great, for 2 laps and then your sat at about 280bhp if not less.)

my advice would be to monitor the IAT see what you are getting now and try find out what IAT the ECU retards the ignition at, then you can look at using a smaller pulley… or do what i did and fit water injection.