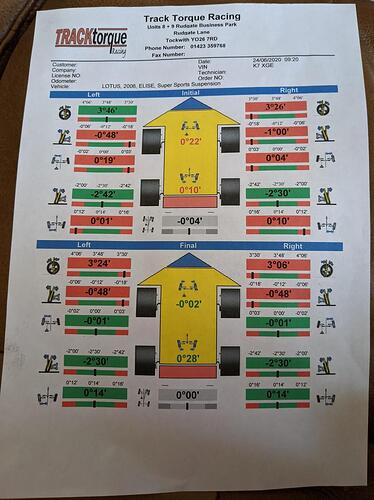

Went for Geo again today, mainly to correct the toe and ride heights after my messing around.

Back to my local haunt for this one.

Other than getting a socially distanced tan in the carpark there wasn’t much to report, cup of tea and a few laps of the estate later and I had a car and print out.

Couple of surprises here, first the OSF camber reading. I specifically recall Dan@HPE saying that my camber was ‘one shim out’ on that corner so he took an extra shim out. It seems the TrackTorque equipment disagrees with that and the shim has been refitted again  It would seem either TT or HPE have got a calibration issue somewhere, but I guess I need to hand in my race driver card as I can’t tell the difference anyway

It would seem either TT or HPE have got a calibration issue somewhere, but I guess I need to hand in my race driver card as I can’t tell the difference anyway

Front toe was always going to be a bit out, but wasn’t expecting a discrepancy from side to side. I know Dan prefers a more neutral toe at the rear as he likes his cars to be a bit tail happy, seems TT have dialled some toe back in to stabilise it at that end.

Ultimately I know what to expect from this geo, TT have done my Elise and the original geo on my Exige with settings very similar to the above so not expecting fireworks, but good to know everything is back in line after my tinkering.

I paid my respects to Grandma while I was there

Car felt well on the way home, still feeling that the addition of the rack riser plates was well worth it. Car just feels like it’s goading me on a bit through quicker corners now, a confidence I didn’t have before.

Back to my AC/Blower issue for a moment, my AC worked flawlessly all the way there, approx 45mins of driving. On the way back the ‘hot/cold’ cycle seemed to return. As it happened I arrived home with the blowers on ‘hot’ so decided to have a quick peek inside again to see if I could catch the blend door in the act and sure enough it was sat on full hot despite the knob being on full cold. Once again I wiggled some wires about and the issue seemed to resolve itself… for a bit.

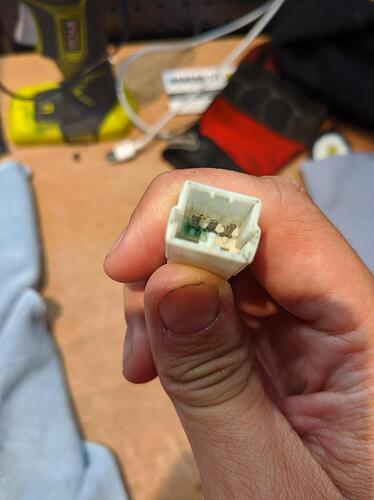

I disconnected the wiring harness for the actuator flap, quite difficult from above but got there in the end. The wires all look tidy enough and there’s no sign of a pinched wire or loose connection but one of the connectors did have a bit of corrosion in it.

I gave it a good clean out and sprayed the connection on the loom with contact cleaner and hooked everything back up… no dice, in face the flap seems to stick more now than it ‘unsticks’  I’m fairly sure that the actuator or flap is not mechanically stuck, but the wiring inside could be questionable if it’s taken on water in the past. Heck the issue could even be further up the loom somewhere, but trying to see that with the clam on just isn’t going to happen.

I’m fairly sure that the actuator or flap is not mechanically stuck, but the wiring inside could be questionable if it’s taken on water in the past. Heck the issue could even be further up the loom somewhere, but trying to see that with the clam on just isn’t going to happen.

Now that I know I can disconnect the wiring ok from the actuator from above, I may just buy a new actuator and hook it up (without attaching it to the heater box, because that’s impossible with clam on) but I can at least see if a new actuator… actuates reliably and then just stick it on a shelf till the clam next comes off.

In the meantime, I may disconnect the wiring from the actuator completely and just fix it in the 50:50 position. In this position with the AC on, the air is nice and cool but not the coldest, but once the AC is switched off, a bit of warm air drifts through - so it should see me through the majority of conditions. Might also try it full cold, actually struggling to remember the last time I used the heater, and it’s a 15min job to push the flap the other way if it gets to October and the car is still taxed etc.