With winter upon us now is a good time as ever to do a suspension refresh.

Hopefully you can give me some advice as I go along.

Please forgive if im posting in the wrong area and mods move it appropriately.

I want to keep the car drivable on the road but also competent on track.

After talking with Nitron my plan is to replace the shocks and springs with Nitron 46 race pro shocks (1 way adjustable) and 450lb front 525lb rear springs with helpers all round.

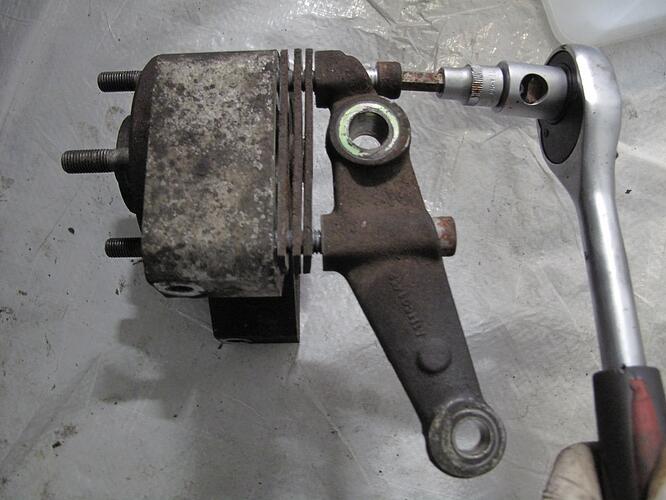

Also I will replace all the original wishbone bushes with bearings and replace the ball joints, drop links, anti roll bar bushes, suspension bolts, uprated toe link kit, new discs and pads.

I am going to refurbish the wishbones by having them sandblasted , zinc passivated then coat with clear por-15.

Apart from the sandblasting of the wishbones I plan to do everything myself, I’m no trained mechanic but I believe there’s more satisfaction to doing it yourself.

I’ll be taking my time (as only a few hours per evening…2-3 times a week) but my aim is to finish beginning of March ready for Angelsey ![]()

Edit: Part way through Day 4 I found an excellent guide tadts.com/instructions/suspension - Replace wishbone bushes and wishbone ball joints (wishbones removed from car)

Day 1

Removed all the non-essential items from the sides of the garage.

Loosened off the wheel nuts, jacking up at point A to put the car on ramps on one side.

Removed the 2 rear under-trays and jacked up the car on the other side at Jack point A. This then allowed me to position axle stands at points B and D.

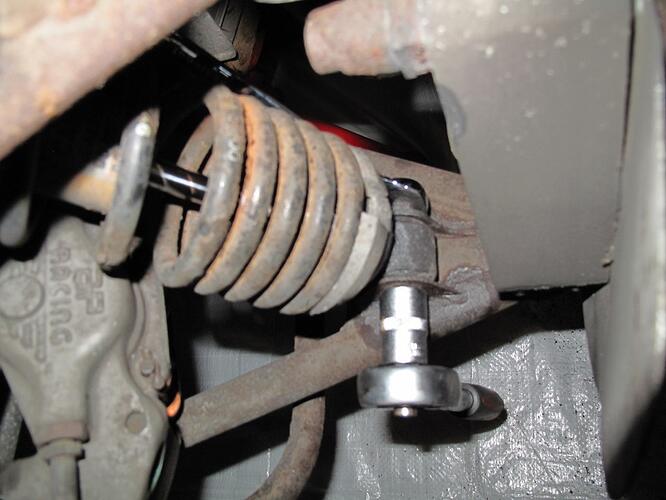

After removing the wheels and placing them underneath the car this is the rear nearside.

…and the front nearside (quite rusty…although the camera flash highlights more than the rear)

Should there be castor washers (shims) packing in the front upper wishbone joints (aft joint of the shock)? Or is that the design?

Do i need to remove the wheel arch liner to gain access to the front wishbone bolt

I sprayed all suspension nuts/bolts and retired for the night.

Day 2

I decided to start on the front nearside.

First off I removed the nut retaining the brake pipe clip.

Then removed the brake caliper with an 8mm allen socket.

…and using a cable tie secured it to the anti-roll bar for now. I will be removing the anti-roll bar later to clean and replace the bushes and give it the anti rust treatment

I then removed the brake disc (no further screws/bolts holding it on)

I then removed the upper strut support bolts using a 17mm socket and 17mm spanner

…and then the lower one

Removed the shock assembly

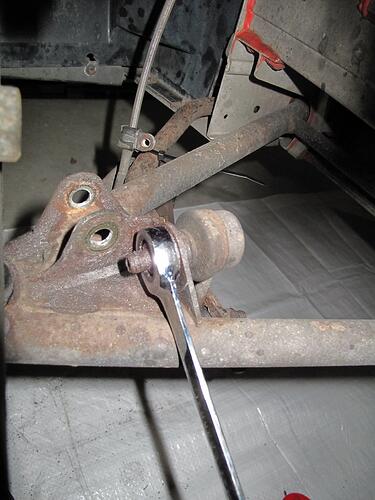

I then loosened off the front tie rod end bolt using a 17mm spanner and lubricated the dust cover (these were replaced last year and will be reused)…

before freeing off the joint using the joint splitter.

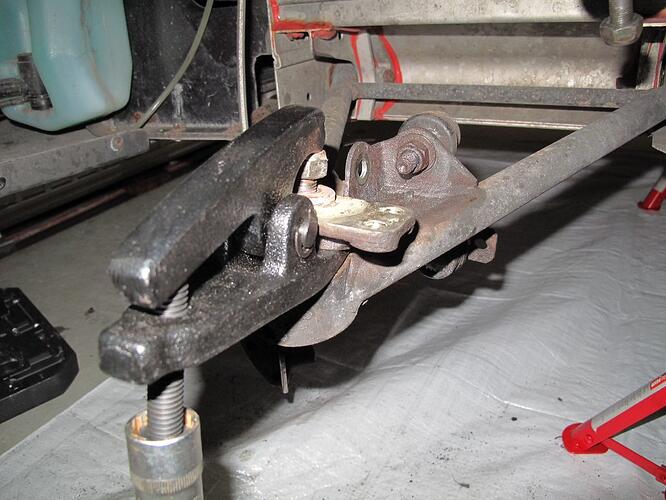

I loosened off the nut holding the upper wishbone to the Hub using a 19mm spanner (wishbone kept in place for now)

…and then the same with the bottom using a 19mm spanner (wishbone kept in place for now)

I then tried to loosen/remove the drop link but the threaded bar just rotated with the nut…

So in summary:

Can the upper wishbone bolts be removed without removing the wheel arch liner?

Should there be any castor shims in the aft upper wishbone joint or is that the design to allow movement/deflection in that area?

How can i remove the droplink to the anti roll bar (I could try putting another nut on it and using 2 spanners)?