Anyone that’s read ‘my’ thread will know that I’ve experienced a bit of an inconsistent flap recently, my AC works great -blows icy cold but occasionally the electric actuator for the heat/cool blend door in the heater box decides to move to the ‘heat’ position, meaning my AC chilled air is routed through a red hot heater matrix before meeting my sweaty face.

The fix for this is probably to change the actuator, it seems like it’s on the blink - but that’s (another) clam off job, draining the AC system, removing a load of AC parts (that are highly likely to break when being unscrewed, ask me how I know) and frankly the problem I have is not frequent or annoying enough for me to go to those lengths unless I have a different additional excuse to remove the front clam.

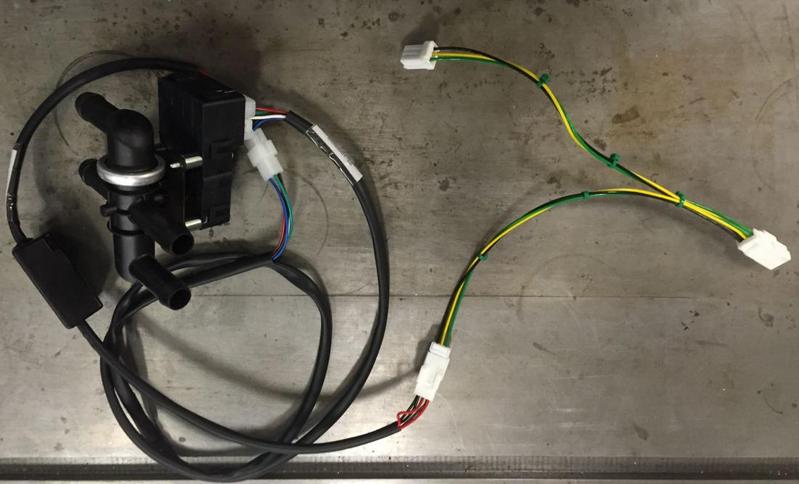

My research on the matter brought to my attention a modification that seems popular in the warmer US States in which a bypass valve is fitted before the heater matrix so that you can actually switch the heater matrix ‘off’, that way regardless of what the blend door flap is doing you can still get cold air through the system.

I’m going to start collecting bits/research and look at doing this to mine - it can be done ‘from above’ and so will be an interim solution to my glitchy flap but even with a fully functional flap this should be considered an upgrade as you can stop the heater box from heatsoaking in summer, degrading the performance of AC and the cold air blowers.

I’ll document it in this thread, both to help other people who may not read my Owners Car thread but also in the hope that it attracts the attention of people who have already done it!

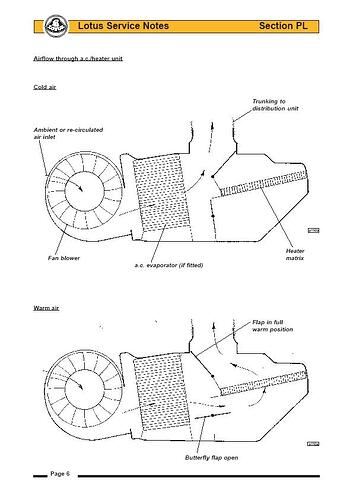

First up, this is how the system is supposed to work.

You can see that the air from the blower always blows through the AC evap unit, and is then either directed straight up to the vents, or via a back door through the heater matrix depending on the position of the blend flap(s). The heater matrix of the Elise/Exige platform ALWAYS has hot water flowing through it, which is what this modification aims to fix, by starving it of hot water, even if the flap was stuck in the lower heat position, the air should still be nice and cool.

The heater matrix cannot be simply blanked off completely as the Toyota engined cars have a feature in which water continues to circulate round after the car is powered off to avoid hot spot damage so whatever solution is used should default the system to “non-bypassed” when the car is switched off.

The first published implementation of this is documented at length here: Heater Core Bypass Mod (Tony Wa) [How To] | The Lotus Cars Community

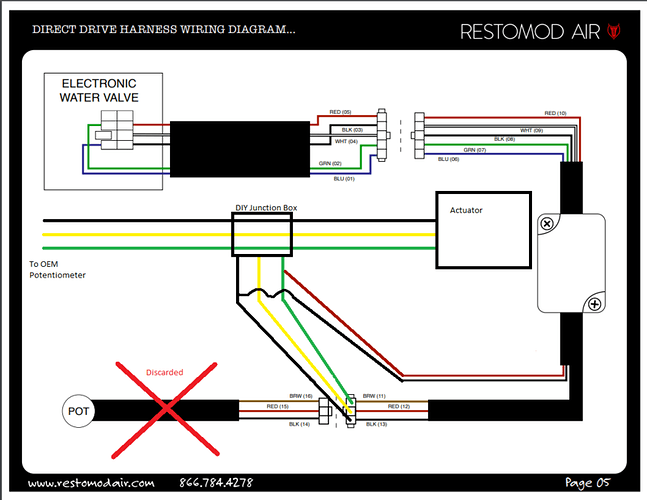

In short, it takes a vacuum feed from the brake booster to deal with the “should only bypass when car is on” requirement, then uses a rocker switch to the cabin to allow the occupants to switch the bypass on or off independently of the original temp dial potentiometer.

That solution is fine, in fact it’s brilliant - but the addition of the extra switch is something I’d like to avoid if viable. It seems like somebody else has investigated that (Electronic Switch for Heater Core Bypass Mod | The Lotus Cars Community) and has essentially converted the variable resistance signal from the potentiometer dial to a binary “hot/cold” signal. This means that no extra switch is needed, and when the dial is set to ‘full cold’ the bypass kicks in, when set to anything else - the bypass is removed. I really like this approach, but by far my weakest area is electronics so I may struggle to get my head around it (alone!).

My plan is to start collecting parts and setup a test rig on my bench, should be easy enough to simulate with some buckets of water, a power source and a potentiometer (can cobble together a long extension lead to the car if needed and use the one in the dashboard).

Once this is done, my hope is that I can have got or cold air regardless of my flap issue. I would potentially disconnect the electrics from my flap and leave it in the ‘warm’ position, then use the bypass exclusively for controlling heat. Obviously I won’t get granular control like this, and I expect the turnaround between heat and cool will be quite slow as the residual temperature in the matrix would need time to drop - but it would work, and once the flap/actuator is returned to service (whenever that is) I will end up with a system that’s a fair lick better than the factory effort.

Welcome any encouragement, experience or thoughts.