We did manage to get the patio finished to a usable state for that intermittent summer of 2019. First the patio retaining wall was built.

IMG_20190515_171527652 by zimbarbaluba, on Flickr

IMG_20190515_201131531 by zimbarbaluba, on Flickr

IMG_20190515_202008392 by zimbarbaluba, on Flickr

It got several coats of paint

IMG_20190616_192747495_HDR by zimbarbaluba, on Flickr

IMG_20190616_192717087_HDR by zimbarbaluba, on Flickr

We had to dig out a drainage channel at the back wall of the house. Some time in the past there was a lean-to on the back here and they had put this concrete slab in at the same height as the damp proof course. I had to get back below that level so I can put a drain in (also still not done yet in 2021).

IMG_20190629_110119365_HDR by zimbarbaluba, on Flickr

IMG_20190629_113814647_HDR by zimbarbaluba, on Flickr

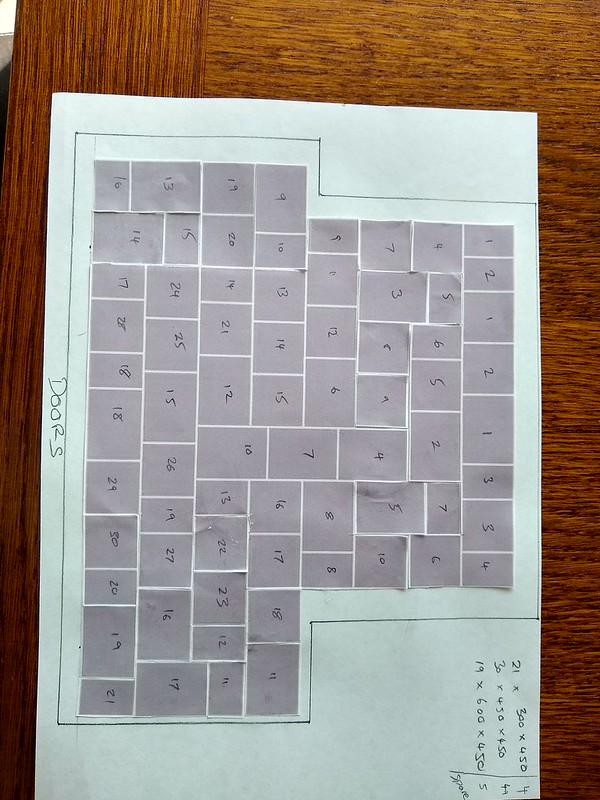

Then I created a template plan for the patio slabs - I bought two kits which included a pre-built pattern so had to make it work for the shape we had.

IMG_20190629_083740538_HDR by zimbarbaluba, on Flickr

Finally, and unfortunately, on the hottest day of the summer 2019, the slabs went down

IMG_20190629_133033844_HDR by zimbarbaluba, on Flickr

IMG_20190629_142015254_HDR by zimbarbaluba, on Flickr

And a few days later I did the pointing

IMG_20190630_185134891_HDR by zimbarbaluba, on Flickr

IMG_20190630_185702070_HDR by zimbarbaluba, on Flickr

I still have a bit of pointing to finish and I need to finish fixing in the capping stones on the top of the wall (using the leftover patio slabs) but it was very nice to have this done and be able to relax outside on nice days. - It’s 2021 and I still haven’t done this. Do you see a pattern emerging!?

That was a bit of a diversion from the garage build but following the purchase of a new daily driver which I want to keep off the street, I need to finish the driveway in front of the garage.

We cleared all the overgrown weeds away again, removed the temporary ramps which had helped get the Elise in and out and started putting in the framework for the concrete pour.

IMG_20190907_162914486_HDR by zimbarbaluba, on Flickr

Put in a drain in front of the garage doors

IMG_20190907_162926582_HDR by zimbarbaluba, on Flickr

Finished the framework, put in the dpm and steel mesh. It’s separated down the middle in order to provide a fall in both directions for the water to drain off.

IMG_20190907_183708985 by zimbarbaluba, on Flickr