Bodywork weekend.

Rear clam was fairly straight forward, I loosely mounted the spoiler uprights to the clam and used those to support it in place on the subframe while I ‘folded’ the corners in under the side panels and loosely bolted those up.

I think I mentioned before, but there’s not really any shimming to do with the 2-Eleven for panel gaps, it all seems to be just loosely bolting up, then manhandling bits into position whilst nipping up the fasteners. There’s enough flex in the bodywork to allow you to line it up with reasonable success, and there are startlingly few fixing points to the chassis itself.

Engine cover on to check for panel gaps, pretty good - at least as good as it was before, maybe a bit better.

Onto the front, I needed a second pair of hands here because you can’t carry and support it alone. It’s light enough, just a bit too floppy and ungainly… I could imagine it just snapping down the middle if you tried to lift it solo.

Slots on a fair bit easier than the Elise/Exige versions as it just kinda sits on top, rather than needing to be fed from the front in a hooking motion.

Again alignment was just a case of jiggling it around before bolting it down. It only rigidly mounts to the chassis via the dashboard/bulkhead thing - all other fixings are just into other pieces of bodywork. The final bit of support will come from the front undertray and wooden splitter.

Mounted the oil coolers which have been cleaned up

And fitted the aero spat things to the front corners and the ‘a’ pillar area.

It’s a relief to have the garage floor cleared, not only for the space but also it marks (another) 3 month period without tripping and walking backwards into a load of fibreglass. Also a relief that all of my chargecooler plumbing fits comfortably into the wheel well.

I still have the carbon skinned covers to go here to cover up all of the electronics/plumbing - they just need a final wet sanding and maybe some lacquer before going in.

Arch liners are about ready to go in at the back, but I did spot a couple of things that I think I failed to document in the thread ages ago.

My Sector111 catch cans have been repurposed from the Exige. They can’t mount to the head as they did on the Exige because the CC piping is in the way here, so they’ve been relocated to the roll bar support. Nicely accessible to drain them off from the wheel arch without removing from the car.

Also lurking in the background is the ITG Stab99 airbox. The EMU black runs MAF-less so really frees up your options for induction. This has a nice bit of a induction noise, not that I’ll hear it on the move…

There’s a temptation to run some fresh air to it, you can see at top of shot that there’s the big round opening from the previous clam mounted ducts for the A/A intercooler. They’re now redundant, so could maybe pipe something around in a convoluted U-Bend. I don’t think I’d direct attach it to the airbox because it might throttle the air supply, but having a bit more fresh air blown into the direction of the airbox can’t hurt.

I thought I’d give the brakes another bleed. I’d had a broom handle jamming the brake pedal down for a few days to see if @Elise_Mark 's technique worked for me.

Initial impressions were underwhelming, pushed pistons back and clamped them. Ran 20PSI through from the Sealey and didn’t really get any satisfying globs of air… but the pedal was no question a lot firmer. I relieved the pressure, popped the pads back in and remounted the calipers and gave it one more round of bleeding. Pedal I think is almost there, I think any real road/track mileage will still produce a bit of sponge but hopefully I can get some shakedown mileage on it, lock up the brakes a few times and then give it one last go.

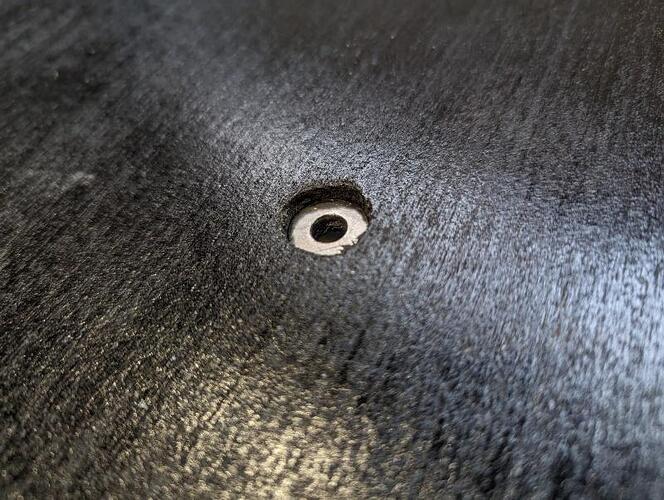

@junks Had been advertising some little gismos, presumable from another OEM that used the same 2-pin connectors for the ABS. These wires are prone to breaking if mishandling them, I know because I’ve done it before. I now treat the ABS wires like I’m diffusing a bomb but these replacement plug-clips should help offer a bit of support for future hamfisting.

I got to spend some time sat in the cockpit to finish off the clam fixings (wee M6 bolts you can just see under the clam line) so I replaced the weather stripping too which the aeroscreen would mount against.

Speaking of which, I decided to break out the spare aeroscreen that the previous owner had supplied with the car. It doesn’t have the hazy/crazed effect of the old one. It does make me very nervous thinking that I’ve now “used up” my spare aeroscreen, so I might be on the lookout for another spare. I imagine once they run out, these will be incredibly expensive to get made up.

A few fixings delicately done up later, and we had giazing back.

You can just see a bit of clumsy rubber trim going around the rear view mirror. It might be some sort of IVA compliance trim but it’s constantly trying to fall off, so I gave it a helping hand. Mirror looks much sleeker now, but still as useless as ever.

With that done I’m now just arch liners, wheels and a splitter away from being able to drive the car. I have Geo booked with @seriouslylotus Wednesday this week so if push comes to shove I can bolt the old splitter on to get it onto the trailer (clam flaps around far too much without a splitter fitted, wouldn’t want to drive it even a few feet like that).

If the weather allows though, I’ll get this finished off. So far it’s primed.

Will give it a fine sanding and then a couple of coats of black then we should be good to go. This is the worst of my attempts, but still pretty damn good. I’ll spend more time (maybe borrow a router) on the better one to give it some nicely finished edges.