Whilst waiting for my suspension to return, I got on with the next job on the list… the supercharger.

I’m not doing anything major, but since I’ve discovered a few broken brackets/incorrectly mounted bits I wanted to get it off the car completely - inspect everything and then bolt it back together properly. It also gives me better access to stuff like the starter motor, so there was a nice bonus there when putting the gearbox accessories back in place.

Getting the unit out isn’t that hard with the clam off, with the clam on it’s still possible but you’d need a pretty intimate knowledge of where all the bolts are I think. Inlet manifold comes off first, then the main blower unit can be just pulled out.

The oil inside the supercharger nose has no published service interval that I can find, but some people have found that they can leak either externally (making a mess) or internally causing invisible damage so it’s worth at least checking levels occasionally. With the supercharger on the car your only way to gauge oil level is to stick a syringe in the fill hole and suck it out, but it’s notoriously difficult to get all of it out so you never really know how much oil you’ve got. I’ve tried multiple times and each time can only extract 60ml or so of oil (it should have 110ml), but with it on the bench I could pour it all out and sure enough the full 110ml came out - so there’s a lesson there, I imagine a fair few people overfill theirs as they incorrectly believe they extracted it all first.

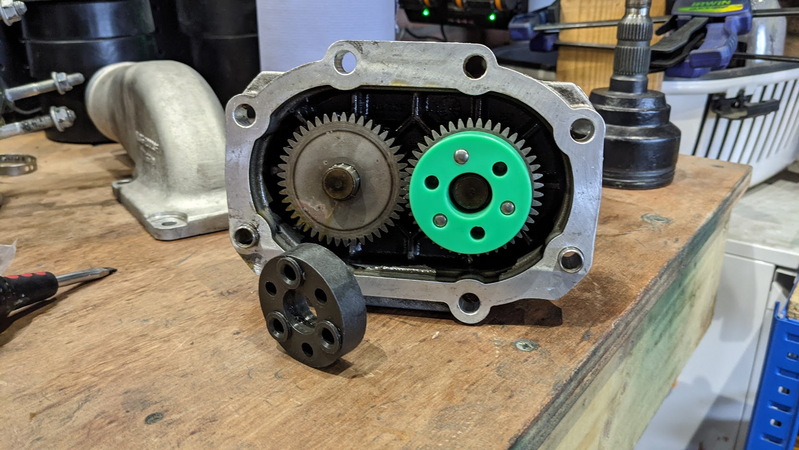

Obviously I then couldn’t help myself having a proper nosey inside.

All looks well, as it should considering I’ve done 90% of the mileage on it (it was replaced in 2012 by a previous owner). I’ve ordered some new o’rings for the various air/inlet adaptors as they’re all a bit crusty and the service kit that I’ve ordered includes the correct oil and a replacement coupler. My coupler is absolutely fine, but they are a wear component that eventually can make for a noisy supercharger (clacking at low RPM) so I’ll stick the replacement in anyway.

Rotors look in fine fettle, the teflon-like coating they have is intact which is better than most pictures I’ve seen of higher mileage units. The needle bearings in the rear of the casing cannot really be serviced, so will just repack them with high temp grease and be on my way.

Removal of the SC also gives easy access to the engine thermostat, so I’ve thrown a new one in whilst in the area. Very cheap part, so just a case of swapping out whilst it’s accessible.

The knock sensor is also right in that region so I took a minute to remove that, clean and refit with the correct torque setting (which can apparently have a big impact on knock detection). For what it’s worth it felt like it was over torqued, but it’s hard to gauge really.

I’m still awaiting the service kit for the SC so I can’t put this part of the car back together yet, so whilst twiddling my thumbs I got the manifold wrapped. Hateful job, and after a summer of running the 2bular manifold I would say it’s not quite mandatory - but the contents of your boot do get a bit toasty.

I’d quite like to get this ceramic coated at some point but budget creep has already gone a bit mental. Maybe one for next year.

There’s been loads of other small activities going on, barely worth writing about but it’s all slowly starting to come together. I expect the wishbones back soon, they’re the main bottleneck now as they prevent me from firing the car up to test whether my gearbox/clutch actually works…