No problem, I originally bought mine direct from them.

I assume “Short axle ratio 5.0: 1 semi helical Evo 3” is Google Translate for the German of “5.1 final drive”?

On tonights’ episode of “Kyle wastes more money on parts that aren’t needed”… Idler Pulley!

When I was changing the crank pulley/seal a few weeks ago I gave all my pulleys a spin by hand and found the idle pulley to be a bit loose and wobbly. Could easily wobble it around on its axis and got a bit of knocking from it, so decided it could go on the Winter20/21 backburner as the belt still ran true etc.

Then lockdown happened, so I went about finding how much a replacement would be, found it was a very common part across a bunch of brands which is great news, as it means it was cheap! (<£30 delivered I think).

I did my research and found a video from an MR2 (2zz swapped) owner doing a similar change and he brought something to my attention, the bolt which holds it on is very long and goes through two tabs on the back of the block with a supporting collar between the tabs. The bolt is so long, you can’t actually pull it out because it hits the subframe. The MR2 fix for this is to pull the bolt out a bit, chop it - then when the replacement arrives simply feed it in the reverse way, as there’s loads of clearance on the “inboard” side.

I asked around to see if this was a done thing, or considered a bit of a bodge and didn’t come up with much… other than one person saying “they all wobble, it’s fine”. After struggling to find a strong opinion either way, I noticed on some old pictures (from when I removed my exhaust last year) that my bolt was already threaded in the “wrong” way, suggesting that the pulley had been off once before… or did Lotus fit them all like that?!

You can just see in the bottom right of this photo a bolt head, well that should be the nut on that side according to the deroure and toyota parts diagrams. My car had the nut on the pulley end instead.

One way to find out, luckily I had a spare Exige sat in my garage so a quick peak down his boot lid vents with a torch showed it was bolted on “wrong” too… so I can conclude from that, Lotus must bolt it in “backwards” to make future maintenance easy… nice one!

Anyway, that’s all a long way round of getting to the point - I fitted the new one tonight and guess what, it wobbles too ![]() When inspecting it on the bench the bearing feels very tight, but as soon as it’s bolted to the block and you can apply a bit of leverage onto it - it gets a slight wobble… fairly less of a wobble than the old one did mind, but I’m sure in 20k miles time it’ll be just the same. So there you go, waste of time and money - but it’s black and not rusty, so points for that.

When inspecting it on the bench the bearing feels very tight, but as soon as it’s bolted to the block and you can apply a bit of leverage onto it - it gets a slight wobble… fairly less of a wobble than the old one did mind, but I’m sure in 20k miles time it’ll be just the same. So there you go, waste of time and money - but it’s black and not rusty, so points for that.

This user has crossed off idler pulley for replacement

I’ve brought a couple of jobs forward from what were supposed to come later in the year (next Winter…).

First of all I received a care package from SeriouslyLotus, not even a global crisis can stop Dave from getting bits to me the following day.

My OEM rubber ARB bushes had been added to my snagging list when I installed the suspension, they were starting to crack a little bit round the edges and the ARB had a fair bit of lateral movement to it. I couldn’t remember from my Elise how much movement was normal, but if I really ragged on it with my hand I could get it to knock a little bit. As it was hard to say whether the bushes, droplinks or both were causing the problem - I just swapped out both. Cheap enough parts anyway.

My ARB is now completely locked in position (can still freely rotate when droplinks are not attached) but there’s no side to side movement at all. I do wonder how many of the odd knocks/creaks/rattles this has eliminated even though the car didn’t sound particularly bad (as far as Lotus’ go) in the first place.

Next I took off my exhaust.

It may be a while before I can update this properly, but I’d been speaking with Chris Tullet Exhausts via Type116 Motorsport recently about potentially having them do a system for my car. Again it was likely to happen towards the end of this year, but with our recently gifted downtime we decided that we could maybe make something happen sooner… essentially I’m getting a mail-order custom exhaust done ![]()

I know CTE have done Lotus/2ZZ exhausts before either through Lotus dealers or as custom one-off jobs but it seems they’ve gone very quiet in recent years on the Lotus side (despite thriving with the VX220’s).

I’ve not gone down the well-trodden path for 2zz exhaust systems for a couple of reasons, I could have just clicked “buy now” and in anywhere between 1 and 9 months could have received a system with known credentials but it’s something I’d like to avoid, at least for now.

The plan is for CTE to use my OEM bits to create a jig. I’m specifically not asking for an emulation of the 2bular backbox hangers because frankly it doesn’t fit right, and that’s not something I want to bring across! Once we have a jig, he’s going to ship my exhaust back to me (if couriers are still running by then…) and in the meantime he can start mocking stuff up. Once lockdown is over, I can take my car down and we can finalise fitment and do some testing.

It’ll be a full system from manifold through to backbox, and hopefully the longer term aim will be to have an off the shelf product that adds to the Lotus community options. Due to the mail-order nature of the jig, getting fitment, performance and sound right may take a few iterations but I feel like I’m in good hands to get that sorted.

Until the jig is built, moving my car around the garage/driveway has become quite a noisy affair ![]()

Ill be following this with interest. Especially the manifold bit.

You are going to have to get a remap after this!

Which rear silencer do you have at the minute? I might like to change mine from the signature to the single oval …

The original plan for the year was to do a few trackdays then look into an ECU to see where the limitations are with the car/engine on a mapping session.

I’m fairly certain the catalytic converter is one such restriction, I think I’ve mentioned it before but it’s an “OEM-style” pattern part unit. With the OEM ones already having history of being “blown out” by SC cars (I can only assume that’s how/why my car ended up with this in the first place) I’ve just got a niggling feeling that this copy one is going to let me down at some point.

So the plan was, ECU/Map → Exhaust System → Remap and see where we’re at. If the car was still loitering around the 260bhp region, then I could be tempted to creep it up with a (slightly) smaller SC pulley but generally I just want to be respectful of the gearbox and have a setup that I know is running bang on.

Lockdown has spun that on its head, I can’t make any progress at all with ECU/Mapping as it stands so I figured I’d get a move on with the exhaust instead. Depending on how scientific I want to get for the sake of the community, I had intended to do a back to back dyno test with the final iteration of the exhaust and my OEM-ish setup without mapping just to get a view on how ‘safe’ it would be to just bolt on and forget.

Once that was done, I’d then go back to Plan A and sort the ECU/Map out to see how much potential the new system unlocks (if any) - this would be useful both for my piece of mind but also for onward marketing if this is to become a new off-the-shelf offering.

My current silencer is an 8" 2Bular, we’ll make sure that the manifold/cat is interchangeable with this to give other people flexibility of which components they want to swap/upgrade, but I intend to end up with a full CTE system on my car.

[quote=Fonzey post_id=239418 time=1586171169 user_id=31614]

New super lightweight exhaust for Lotus Exige - YouTube ![]()

[/quote]

PARDON? :mrgreen: :mrgreen: :mrgreen: :mrgreen:

As previously mentioned, manifolds seem to make a huge difference to mapping on the SC cars, my car ran dangerously lean on a couple of occasions when changing manifolds, interestingly we barely saw any changes with the actual box changes if the pipework diameter stayed the same, just a couple of HP here and there and quite often a lot more noise.

Love the video by the way ![]()

Yep I’ve seen some pretty convincing comparison tests with the manifolds that are already available on the market, clearly strong gains to make.

I wasn’t initially chasing gains, the cat (as I keep mentioning) makes me nervous - options for a drop-in replacement of the cat are limited as many are designed to go hand in hand with a new matching manifold as more elaborate manifold designs require them to be ‘longer’ and hence eating into the real estate of the OEM cat. So then I start looking at manifold/cat combos and then before I know it I’m shipping my stuff off to CTE.

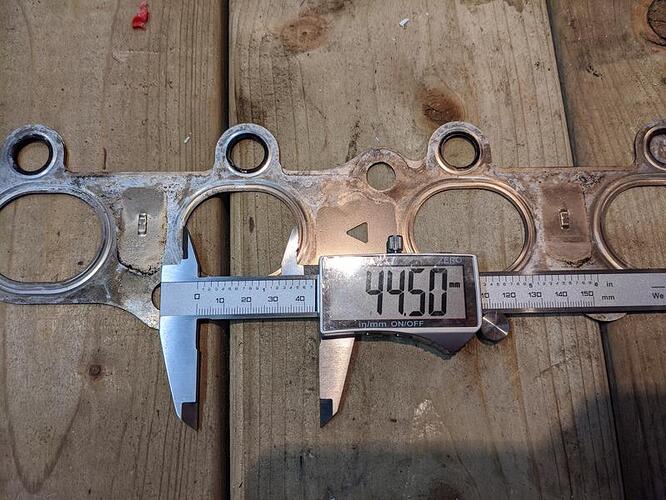

I did some measurements out of interest before it shipped…

Now I know bigger is not always better, and I know there’s a lot of black magic (science) that goes into appropriate manifold length/bore/etc - but it seems to be by just having the pipework be a bit closer to the exhaust port size that there are some easy improvements to make right out of the gates…

Equal length FTW

These were my manifolds that I have made for my c63. Yielded 30bhp/30ibft without mapping.

Woooof, they look a bit of alright don’t they?!

As a long time Subaru fanboy, I’ve been brought up to dislike equal length because it makes the burble go away ![]()

Beautiful pipework ![]()

Like most people I’ve spent the last few weeks cleaning the car to within an inch of its life. Did it over three weekend really just to pace it out:

- Clean and Clay

- Polish

- Wheels and all the other bits (glass, engine bay, etc)

I’ll throw some obligatory pics in, but nothing that hasn’t been seen before. Plus with the combination of lockdown and not having an exhaust, it’s not like I can take the car anywhere pretty for some nice ‘done’ shots…

Car was washed as normal, did a bit of de-tarring but gave the iron-x a miss as frankly it didn’t seem needed. For the polishing I didn’t feel it needed anything too aggressive so went with my tried and tested idiot proof Meguairs microfibre kit, it’s great for getting decent results from a DA polisher but will never get the peak performance of a proper pad/compound setup on a rotary. It’s also really forgiving compound if you get it on “non paint” parts of the car, wipes off dead easy without staining so takes the pressure off of masking considerably.

I certainly got through the bulk of the (very light) swirling but there’s a couple left that are still within correctable range, so maybe next summer I’ll step up the efforts (read: pay somebody else to do it).

The car certainly came up well, Laser Blue never failing to make me warm and fuzzy inside as a really rewarding colour to polish up.

Sealed with Sonax NPT, pretty much finishing off my stock of it so might try something new next year. In the meantime it’ll get topped up every wash via the Sonax BSD quick detailer spray.

Pretty much anything black on the car inside or out got a wipe down with Aerospace 303 protectant stuff, such a good all-rounder.

Wheels all came off during a day in the garden, some generic megs’ wheel cleaner followed by a claying, hand polish with some random compound I had lying around and then coated with the same Sonax NPT as used on the car. I’ll probably be bedding in new brake pads soon(?!) so I might come back to them with a sacrificial layer of something else just to keep on top of the mess.

I’m not a huge lover of satin/matte wheels, had I had them refurbed myself they would probably have been gloss but after cleaning them up they looks pretty nice, picking up just enough of a shine to be satisfying.

I did however find something quite upsetting…

Two things wrong with this, first the screw and second the wear pattern - the outside edge is almost demolished, compared to the tyre on the other side of the car (OS Front) which is almost brand new. Looks like the few miles I did with my “doing it by eye” geo has utterly destroyed it. I guess looking on the bright side at least the screw is in the tyres that’s trashed anyway, but still will replace the front pair and leave the one remaining good one as a useful spare. Rears probably have a trackday or two left in them so can address them later.

Engine bay got a wipe down, plus spotted a bolt missing from the charge cooler which I sorted. Woops.

Interior still needs going, maybe a job for week 4…

When I was laying on the floor polishing the lower parts of the car, I spotted some parts that bugged me as they’re rusty, minging and (sort of) on display so they came off for a rather over engineered process to clean them up and repaint.

5 points for guessing what they are.

Great update. Car looks well.

I am purely guessing here : the parts are the sidepod holders?

Diffuser attachy things. Been there, done that. Car looks great btw ![]()

Cheers Gents,

dingdingding, 5 points to Jonny. ![]()

I forgot to mention, my wheel centrecaps are looking tatty - doubt they’re genuine based on the state of them. I’m not forking out Lotus prices for replacements, so on the hunt for some somewhere-near decent dome gel stickers in 50mm diameter if anyone can recommend a printers or generic knock-off shop. There’s just one eBay shop I can find listing them in 50mm and they’re apparently closed for the duration of the ‘crisis’.

Also on the topic of Lotus logos, my steering wheel hornpush is looking a little faded so might be on the lookout for one of those too which’ll fit my Sparco300.

Good grief, Karl, you’re introducing me to a whole new world of car care products. Never used or handled a clay bar in my life for fear of doing irreparable damage.

When I took off wheels a few days ago I only cleaned the inner rims, intending to clean the whole car and the outer rims later. But I failed to get round to it( I’m awaiting delivery of some foam stuff for my new lance) Instead, I’m sitting about reading copies of Evo and Octane I have had in stock since last year, popping a bit of air in the tyres and occasionally doing a bit of exercise on my turbo trainer.

I need to focus! Top job.

And I notice you have a little helper on hand. . .

I intentionally veer away from using the term ‘detailing’ when I have a go, because it’s discrediting a pretty skilled trade!

Claying in theory should be safe as houses, I think you can get cloths/mitts with “clay” attributes built in nowadays which probably makes it a bit more user friendly. I would never do it though unless I planned to machine polish afterwards, as I find it hard to believe you can thoroughly clay a car without introducing more swirls as a result.

As for polishing, DA polishers seem to be pretty idiot proof. When I first had mine I had a scrap panel lying around that I did some practise on to see just how abusive I’d need to get to cause damage. It turns out, you can only really cause damage if you hold it in one position for a time on a ridge or edge, holding it on a flat surface just seems to dissipate the heat too quickly to cause any harm (which is in turn why a rotary has a better ‘peak’ potential in the right hands).

I’d love to learn it all properly with a rotary, but if I’m honest once I get started - I wish I never did, it’s a lot of work and even if you spend £2-300 for a ‘detail’ by a pro, it’s a bloody bargain to be honest. I probably spent £100 just on bits to top up my supplies to allow me to tackle this work, and when you add in 8-10hours labour it’s just not worth DIY’ing it! Lockdown is obviously a different story though, so I got stuck in regardless.